Chirality graphite phase carbon nitride polymer semiconductor photocatalyst

A graphite phase carbon nitride and photocatalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical/physical process, etc., to achieve good activity stability and good controllability and broad-spectrum, the effect of improving the performance of photocatalytic hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

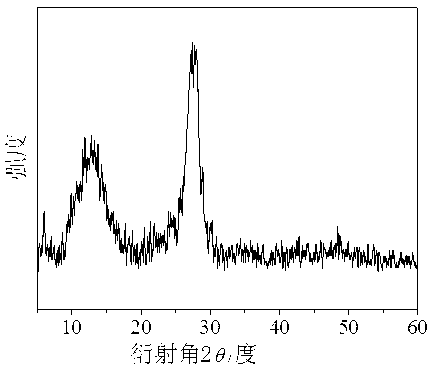

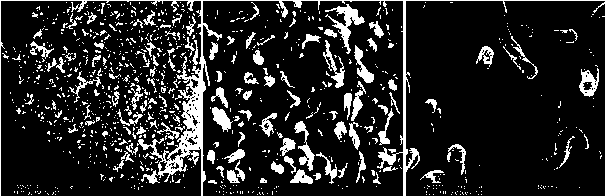

Embodiment 1

[0026] Mix L-alanine, sodium hydroxide solution, and 30% acetone solution, add tetradecyl chloride and NaOH solution dropwise at 0°C, and maintain the pH at 12. After the reaction, add HCl solution to adjust the pH to 1. Stir, wash, and dry to obtain C 14 -L-AlaA. Take 0.3g C 14 - Add 10g water and 10g NaOH (0.1mol / L) solution to L-AlaA, stir at room temperature to dissolve, then add 10g HCl (0.01mol / L) solution, stir at 22°C for 1h, add 0.23g 3-aminopropyltriethyl The mixture of oxysilane and 1.46g ethyl orthosilicate was stirred for 0.5h, allowed to stand for 1 day, centrifuged, washed with water, and dried. Chiral mesoporous silica was calcined at 550°C for 6h, ground, added 1 mol / L HCl, stirred at 80°C, centrifuged, dried, and ground. In a round bottom flask, add cyanamide and treated chiral mesoporous silica (mass ratio: 6:1), vacuumize, heat and sonicate, and stir at 60°C. Wash with water, take the precipitate, dry and grind. The solid powder in N 2 Calcined at 550...

Embodiment 2

[0028] Mix L-alanine, sodium hydroxide solution, and 30% acetone solution, add tetradecyl chloride and NaOH solution dropwise at 0°C, and maintain the pH at 12. After the reaction, add HCl solution to adjust the pH to 1. Stir, wash, and dry to obtain C 14 -L-AlaA. Take 0.3g C 14 - Add 10g water and 10g NaOH (0.1mol / L) solution to L-AlaA, stir at room temperature to dissolve, then add 10g HCl (0.01mol / L) solution, stir at 22°C for 1h, add 0.23g 3-aminopropyltriethyl The mixture of oxysilane and 1.46g ethyl orthosilicate was stirred for 0.5h, allowed to stand for 1 day, centrifuged, washed with water, and dried. Chiral mesoporous silica was calcined at 550°C for 6h, ground, added 1 mol / L HCl, stirred at 80°C, centrifuged, dried, and ground. In a round-bottomed flask, add cyanamide and treated chiral mesoporous silica (mass ratio: 7:1), vacuumize, heat and sonicate, and stir at 60°C. Wash with water, take the precipitate, dry and grind. The solid powder in N 2 Calcined at 5...

Embodiment 3

[0030]Mix L-alanine, sodium hydroxide solution, and 30% acetone solution, add tetradecyl chloride and NaOH solution dropwise at 0°C, and maintain the pH at 12. After the reaction, add HCl solution to adjust the pH to 1. Stir, wash, and dry to obtain C 14 -L-AlaA. Take 0.3g C 14 - Add 10g water and 10g NaOH (0.1mol / L) solution to L-AlaA, stir at room temperature to dissolve, then add 10g HCl (0.01mol / L) solution, stir at 22°C for 1h, add 0.23g 3-aminopropyltriethyl The mixture of oxysilane and 1.46g ethyl orthosilicate was stirred for 0.5h, allowed to stand for 1 day, centrifuged, washed with water, and dried. Chiral mesoporous silica was calcined at 550°C for 6h, ground, added 1 mol / L HCl, stirred at 80°C, centrifuged, dried, and ground. In a round bottom flask, add cyanamide and treated chiral mesoporous silica (mass ratio: 8:1), vacuumize, heat and sonicate, and stir at 60°C. Wash with water, take the precipitate, dry and grind. The solid powder in N 2 Calcined at 550°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com