Catalyst for macro-porous oxide supported core-shell structure nanoparticles and preparation method of catalyst

A technology of core-shell structure and nanoparticles, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Noble metal particles are not easy to uniformly load and other problems, to achieve the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] Preparation method of three-dimensional ordered macroporous simple oxide support:

[0076] 1) Monodisperse polymer microspheres were prepared by soap-free emulsion polymerization

[0077] Add 50mL of acetone and 150mL of double distilled water to a 1000mL four-neck flask, preheat to 70°C with a 70°C water bath, and add 70mL of monomer methyl methacrylate (or styrene) to the preheated four-neck flask. while preheating the reactants, weigh 0.090g potassium persulfate and 0.1538g azobisisobutyronitrile (AIBN), dissolve in 150mL water to obtain an aqueous initiator solution, and heat the water bath to 70°C; the monomer to be reacted When preheated to 70°C, add the initiator aqueous solution at 70°C, and continue to stir for 2-10 hours to obtain a monodisperse polymethyl methacrylate (or polystyrene) microsphere emulsion with a solid content of 5-10%;

[0078] 2) Preparation of colloidal crystal templates by centrifugal deposition method or evaporative deposition method

...

Embodiment 13D

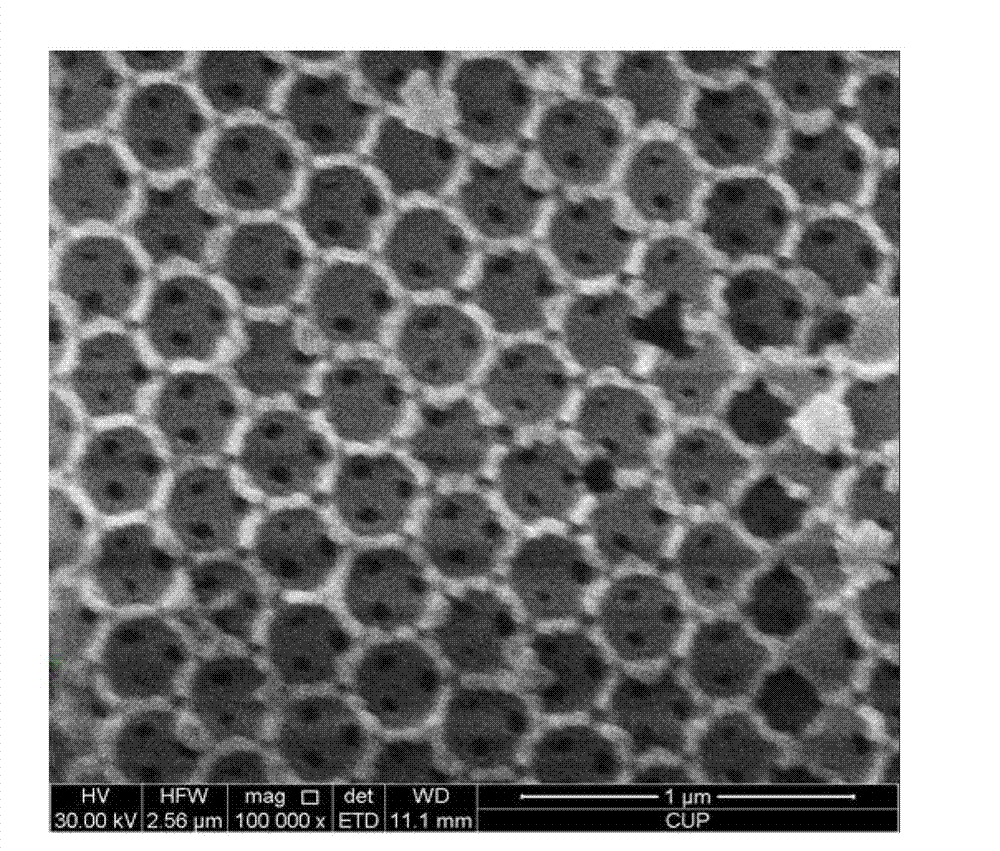

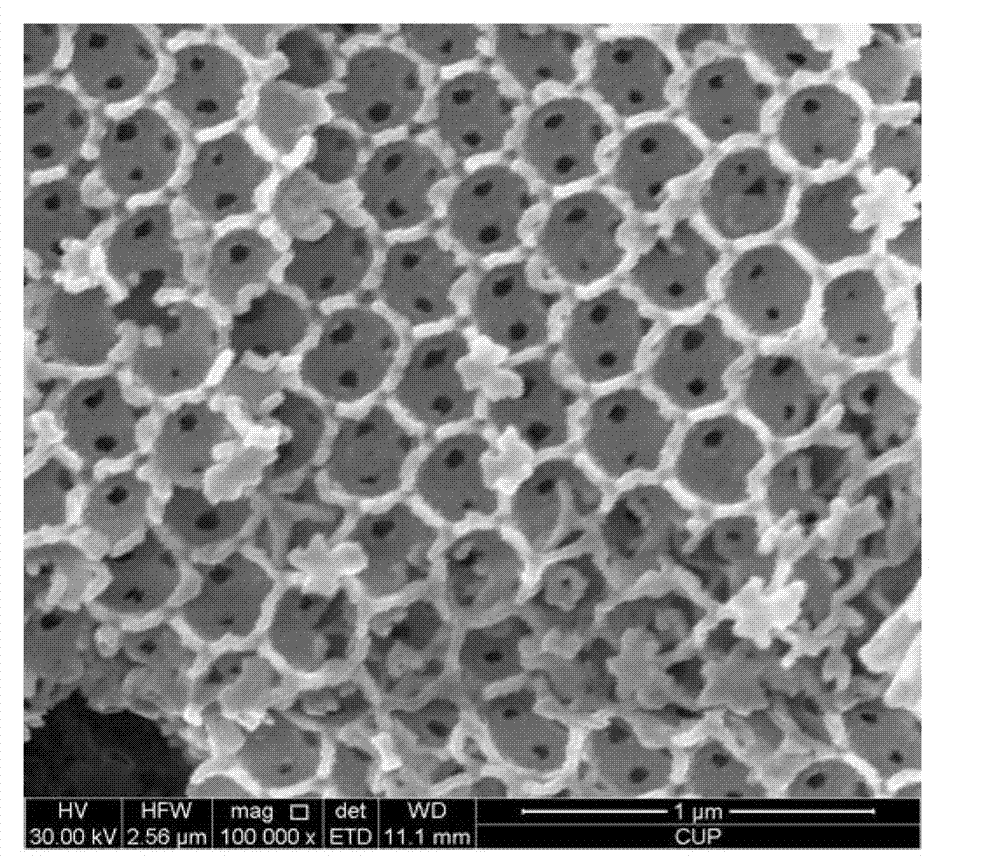

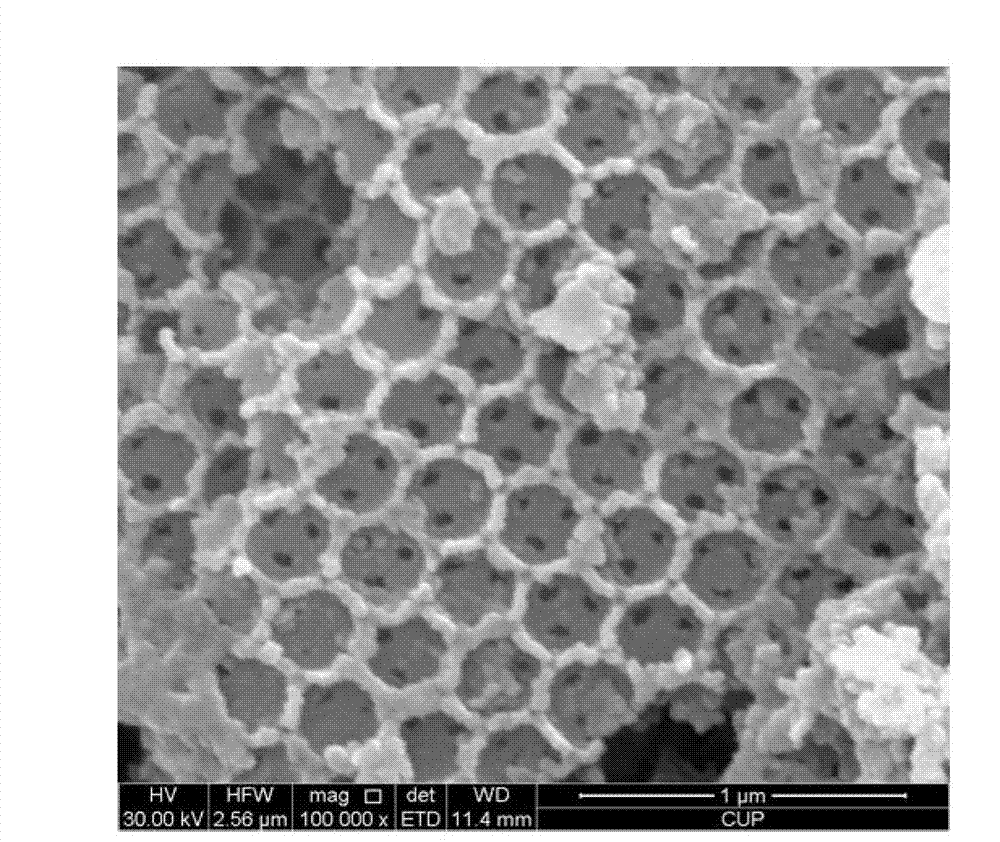

[0084] Example 13DOM AuCeO 2-δ / ZrO 2 catalyst

[0085] This embodiment provides a 3DOM AuCeO 2-δ / ZrO 2 The preparation method of catalyst, it comprises the following concrete steps:

[0086] The precursor salt HAuCl with a concentration of 12.12 mmol / L was 4 aqueous solution, cerium nitrate hexahydrate (with HAuCl 4 The molar ratio of 10:1) with 0.5g of 3DOM ZrO 2 Mixing (the loading amount of Au is controlled to be 0.5-8wt%), and at the same time, a stabilizer PVP with a concentration of 1.2mol / L (the addition amount is the same as that of HAuCl) is added. 4 The aqueous solution is the same) to obtain the aqueous solution of the precursor salt of Au and cerium nitrate, and the ratio of different raw materials is shown in Table 1.

[0087] The aqueous solution of the prepared Au precursor salt enters the membrane reactor under the action of the peristaltic pump, and the hydrogen input device is activated at the same time. Hydrogen bubbles promote the mixing of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com