Biological active microsphere and preparation method thereof

A biologically active and microsphere technology, applied in the field of biomedical material preparation, can solve the problems of cumbersome preparation of microemulsions, unfavorable industrial production, and complicated preparation methods, and achieve excellent fluidity, adjustable particle size, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

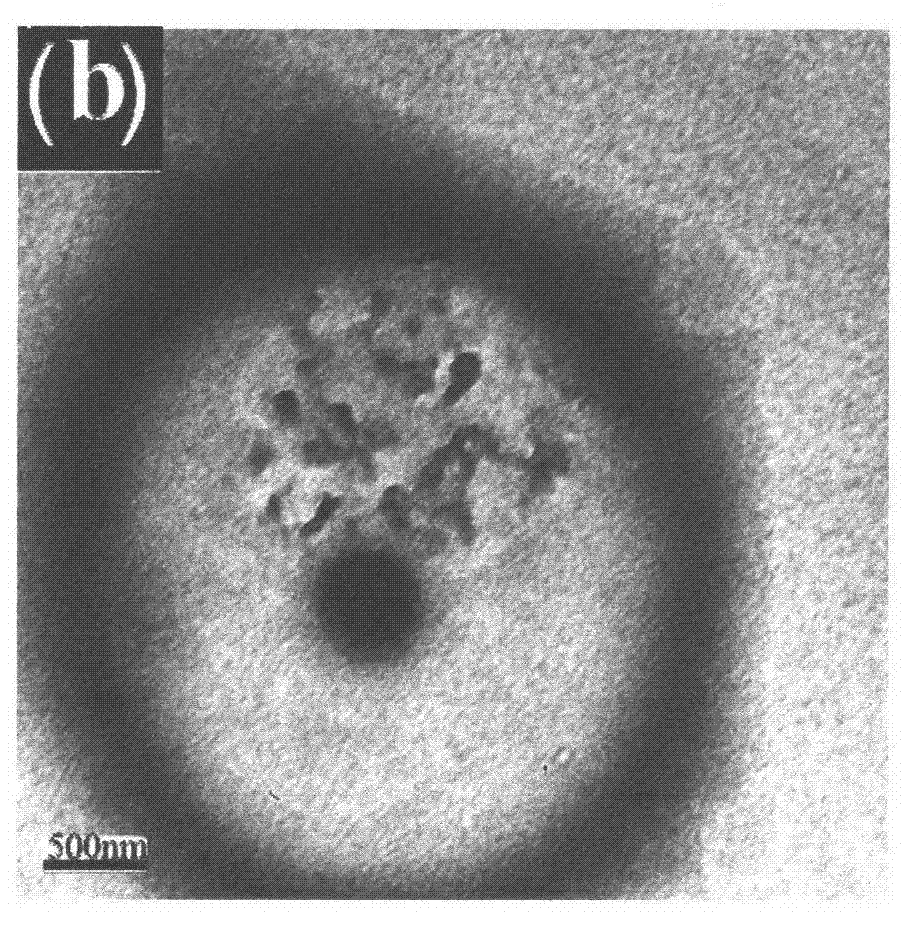

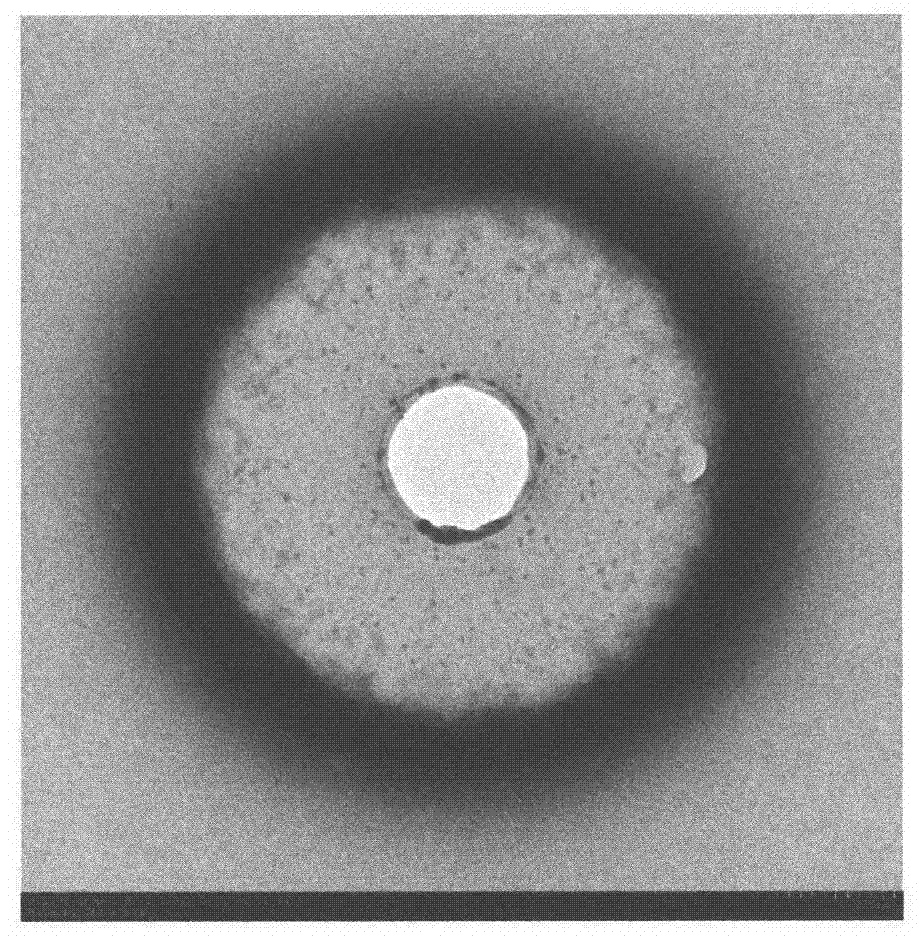

Image

Examples

Embodiment 1

[0034] (1) Dissolve 0.2 gram of citric acid in 30 milliliters of absolute ethanol in the aqueous solution, the mol ratio of citric acid and tetraethyl orthosilicate is 0.017, stir magnetically for 10 minutes and mix well, then add 1.04g polyethylene glycol 6000 , continue stirring for 1 hour to form solution A;

[0035] (2) Add 12.5 grams of tetraethyl orthosilicate (TEOS), 1.45 grams of triethyl phosphate (TEP), and 8.501 grams of calcium nitrate tetrahydrate to the solution A obtained in step (1) in order. A raw material is fully hydrolyzed at an interval of 30 minutes, and sol B is formed after being fully stirred evenly;

[0036] (3) Put the sol B obtained in step (2) into a sealed 50ml plastic centrifuge tube and age at 60°C for 24 hours to obtain a wet gel;

[0037] (4) Washing the wet gel obtained in step (3) with deionized water and absolute ethanol three times to remove impurities, drying at 37°C for 24 hours, and then freeze-drying for 24 hours to obtain a xerogel; ...

Embodiment 2

[0041] (1) Dissolve 0.2 gram of citric acid in the aqueous solution of 30 milliliters of absolute ethanol, the mol ratio of citric acid and tetraethyl orthosilicate is 0.017, stir magnetically for 10 minutes and mix well, then add 1.25 gram of polyethylene glycol 4000, Stirring was continued for 1 hour to form solution A;

[0042] (2) Add 12.5 grams of tetraethyl orthosilicate (TEOS), 1.45 grams of triethyl phosphate (TEP), and 8.051 grams of calcium nitrate tetrahydrate to the solution A obtained in step (1) in sequence. A raw material is fully hydrolyzed at an interval of 30 minutes, and sol B is formed after being fully stirred evenly;

[0043] (3) Put the sol B obtained in step (2) into a sealed 50ml plastic centrifuge tube and age at 60° C. for 24 hours;

[0044] (4) The wet gel obtained in step (3) was washed 3 times with deionized water and absolute ethanol respectively;

[0045] (5) drying the wet gel in step (4) at 37° C. for 24 hours, and then freeze-drying for 24 ...

Embodiment 3

[0049](1) Dissolve 0.88 milliliter, 2 mol / liter hydrochloric acid in 30 milliliters of absolute ethanol aqueous solution, the molar ratio of hydrochloric acid to tetraethyl orthosilicate is 0.025, stir magnetically for 10 minutes and mix well, then add 1.82 grams of polyethylene Diol 10000, continue stirring for 1 hour to form solution A;

[0050] (2) Add 14.58 grams of tetraethyl orthosilicate (TEOS), 1.45 grams of triethyl phosphate (TEP), and 6.202 grams of calcium nitrate tetrahydrate to the solution A obtained in step (1) in order. A raw material is fully hydrolyzed at an interval of 30 minutes, and sol B is formed after being fully stirred; (3) The sol obtained in step (2) is put into a sealed 50ml plastic centrifuge tube and aged at 60° C. for 24 hours;

[0051] (4) The wet gel obtained in step (3) was washed 3 times with deionized water and absolute ethanol respectively;

[0052] (5) drying the wet gel in step (4) at 37° C. for 24 hours, and then freeze-drying for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com