Positive material for magnesium cell, preparation method of positive material and magnesium cell

A positive electrode material, magnesium battery technology, applied in battery electrodes, dry batteries, circuits, etc., can solve problems such as environmental pollution and high production costs, and achieve the effects of alleviating resource shortage, high voltage, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Weigh 9.0075g of ferric oxide, 0.5004g of acetylene black, and 0.5021g of graphite, and put them into a corundum ball mill jar with a ball-to-material ratio of 5:1, use 30ml of absolute ethanol as a dispersant, and The ball mill was intermittently milled at a speed of 400r / min for 4 hours, and then the slurry mixture after ball milling was dried in an oven at 60°C to obtain the precursor of the positive electrode material for magnesium batteries, and then the precursor of the positive electrode material for the magnesium battery was dried at a speed of 300-500r on the ball mill. Grinding at a speed of 1 / min to obtain a cathode material for a magnesium battery.

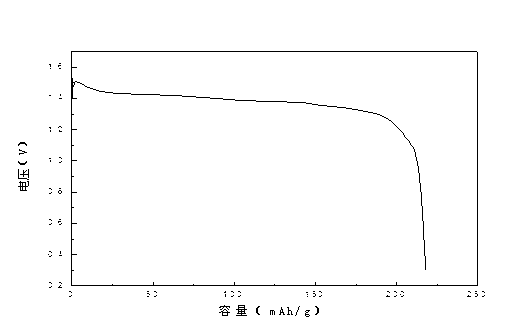

[0034] Weigh 0.1507g of the aforementioned magnesium battery positive electrode material on an electronic balance and attach it to the stainless steel current collector as the positive electrode of the magnesium battery, configure 1mol / L sodium nitrate as the electrolyte, pure magnesium as the negat...

Embodiment 2

[0035] Embodiment 2: Take by weighing 9.0025g of ferric oxide, 0.5064g of acetylene black, and 0.5023g of graphite, and put them into a corundum ball mill jar at a ratio of 5:1 with the ball-to-material ratio, and use 30ml of absolute ethanol as a dispersant. The ball mill was intermittently ball milled at a speed of 400r / min for 4 hours, and then the slurry mixture after ball milling was dried in an oven at 40°C to obtain the precursor of the positive electrode material for magnesium batteries, and then the precursor of the positive electrode material for the magnesium battery was dried at a speed of 300-500r on the ball mill. Grinding at a speed of 1 / min to obtain a cathode material for a magnesium battery.

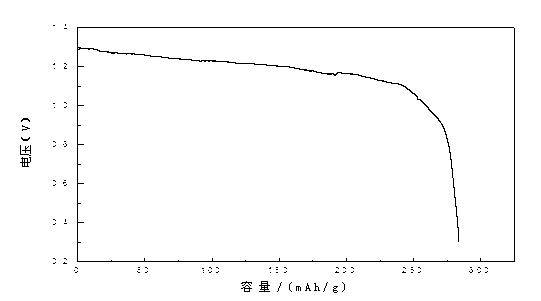

[0036] Weigh 0.1521g of the aforementioned magnesium battery positive electrode material on an electronic balance and attach it to the stainless steel current collector as the positive electrode of the magnesium battery. Configure 1mol / L magnesium acetate as the electrol...

Embodiment 3

[0037] Embodiment 3: Weigh 8.5065g of ferric oxide, 0.5014g of acetylene black, 0.5003g of graphite, and 0.5021g of manganese dioxide, put them into a corundum ball mill jar with a ball-to-material ratio of 5:1, and use 30ml of absolute ethanol As a dispersant, on a planetary ball mill, intermittent ball milling at a speed of 400r / min for 4h, then dry the slurry mixture after the ball milling in an oven at 60°C to obtain the precursor of the positive electrode material for magnesium batteries, and then Grinding on a ball mill at a speed of 300-500r / min to obtain a cathode material for a magnesium battery.

[0038] Weigh 0.1221g of the aforementioned magnesium battery positive electrode material on an electronic balance and attach it to the stainless steel current collector as the positive electrode of the magnesium battery. Configure 1mol / L magnesium acetate as the electrolyte, pure magnesium as the negative electrode and current collector, and add an alkaline diaphragm in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com