Preparation method of super-heat-resistant organic/inorganic composite film

An inorganic composite, super heat-resistant technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of heat resistance, influence and insignificant effect of heterogeneous multi-layer composite diaphragms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

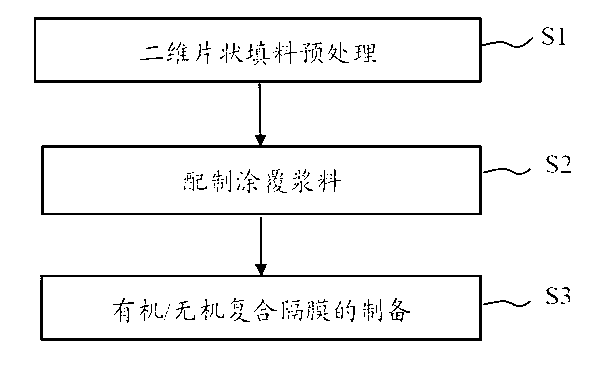

[0039] The embodiment of the present invention provides a method for preparing a super heat-resistant organic / inorganic composite diaphragm, which includes the following steps:

[0040] S01. Pretreatment of two-dimensional flake packing:

[0041]Dispersing the two-dimensional flake filler in ethanol, dispersing it under the action of ultrasonic vibration, washing and drying the treated two-dimensional flake filler for later use;

[0042] S02. Configuration of coating slurry:

[0043] Mix the pretreated two-dimensional flake filler with a binder solution to make a coating slurry, and the binder solution is composed of a binder and deionized water mixed in proportion; wherein, the pretreated two-dimensional flake The mass ratio of filler to binder is 1-20:1;

[0044] S03. Preparation of multilayer composite separator:

[0045] The coating slurry is coated on the surface of the polyolefin microporous diaphragm and dried to obtain a super heat-resistant organic / inorganic compos...

Embodiment 1

[0055] A method for preparing a super heat-resistant organic / inorganic composite diaphragm, comprising the steps of:

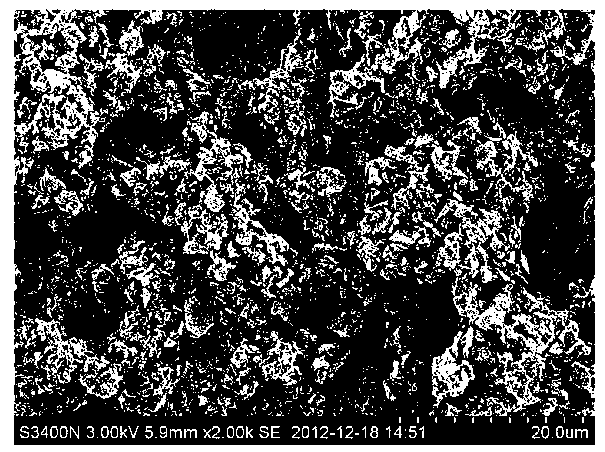

[0056] S11 Treat nano-sized zirconium phosphate and ethanol in an ultrasonic disperser with a mass ratio of 1:10 at a frequency of 5MHz for 2 hours, then reflux the pretreated powder with water for 2 hours, and dry it in an oven at 80°C for 24 hours for use.

[0057] S12 Take polyvinyl alcohol and deionized water at a mass ratio of 1:5 and stir at 70°C for 3 hours to prepare a binder solution. The pretreated powder and the binder are prepared into a coating slurry by stirring according to the mass ratio of 1:8.

[0058] S13: Soak a 20um thick dry-process PP microporous membrane in the slurry for 30 minutes, take it out and dry it in a vacuum oven at 90°C for 30 minutes to prepare a multilayer organic-inorganic composite membrane.

[0059] The heat resistance of the coated separator is better and the improvement is obvious.

Embodiment 2

[0061] A method for preparing a super heat-resistant organic / inorganic composite diaphragm, comprising the steps of:

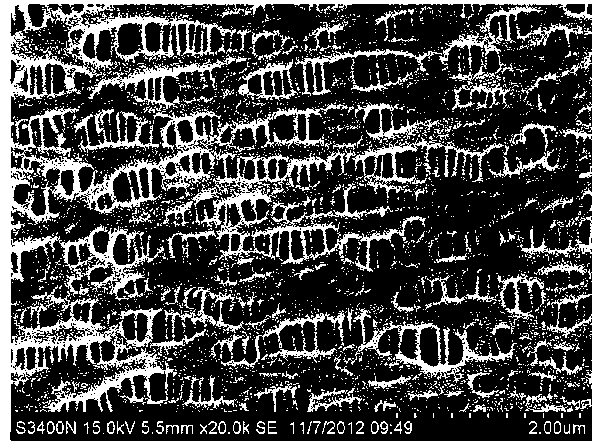

[0062] S21 Treat micron-sized montmorillonite and ethanol in an ultrasonic disperser at a frequency of 5MHz for 2 hours at a mass ratio of 1:10, then reflux the pretreated powder with water for 3 hours, and dry it in an oven at 80°C for 24 hours for later use .

[0063] S22 Take methyl cellulose and deionized water at a mass ratio of 1:5 and stir at 70°C for 4 hours to prepare a binder solution. The pretreated powder and the binder are prepared into a coating slurry by stirring according to the mass ratio of 1:8.

[0064] S23: Soak a 25um thick dry-process PE microporous membrane in the slurry for 30 minutes, take it out and dry it in a vacuum drying oven at 90°C for 30 minutes to prepare a multilayer organic-inorganic composite membrane.

[0065] The heat resistance of the coated separator is better and the improvement is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com