Multiphase flow erosion local corrosion testing apparatus

A technology for localized corrosion and testing devices, which is used in measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of electrochemical signal differentiation and uneven distribution of corrosion samples that cannot be eroded, and achieves a simple structure. , Low production cost, good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the drawings.

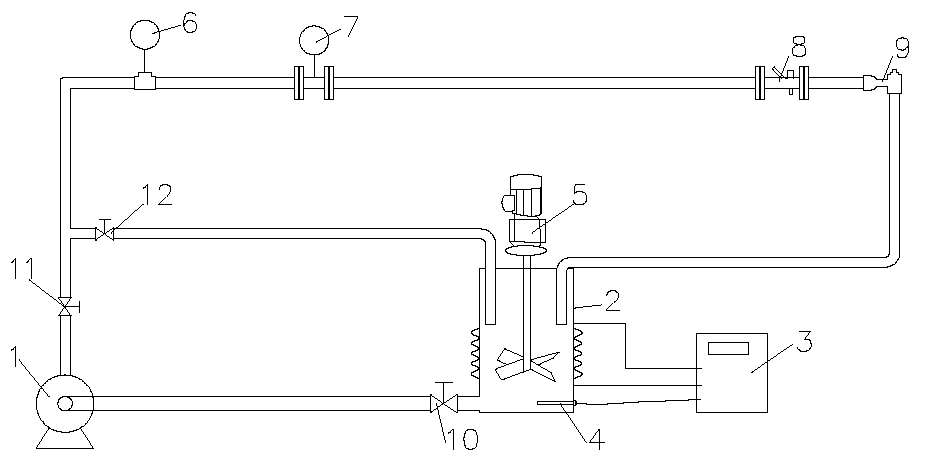

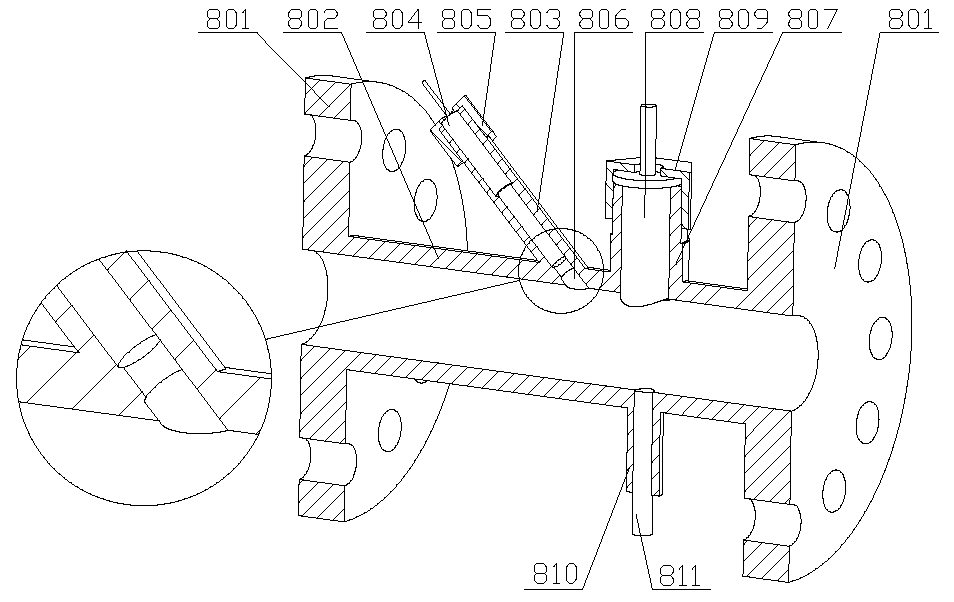

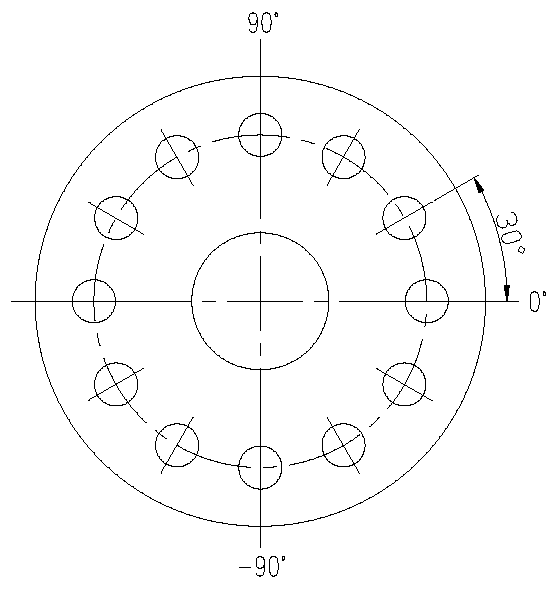

[0025] Such as figure 1 As shown, the multi-phase flow erosion local corrosion test device includes slurry pump 1, slurry tank 2, agitator 5, pressure gauge 6, electromagnetic flow meter 7, pipe flow scouring pipe section 8, jet scouring pipe section 9, thermocouple 4. Low temperature constant temperature circulator 3; slurry tank 2 is used to contain the test medium, and a stirrer 5 is installed above the slurry tank 2 to stir the medium in the slurry tank 2; the slurry tank 2 is equipped with a thermocouple 4, The thermocouple 4 is connected to the low temperature thermostat circulator 3. The thermocouple 4 monitors the temperature of the medium in the slurry tank 2, and the low temperature thermo circulator 3 controls its own working state according to the value measured by the thermocouple 4 to adjust the temperature in the slurry tank 2. Medium temperature; the bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com