Multifunctional underground roadway tunneling locomotive

A multi-functional technology for underground tunnels, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as slow progress, inability to realize medium-depth blasting, and low utilization rate of blasting holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

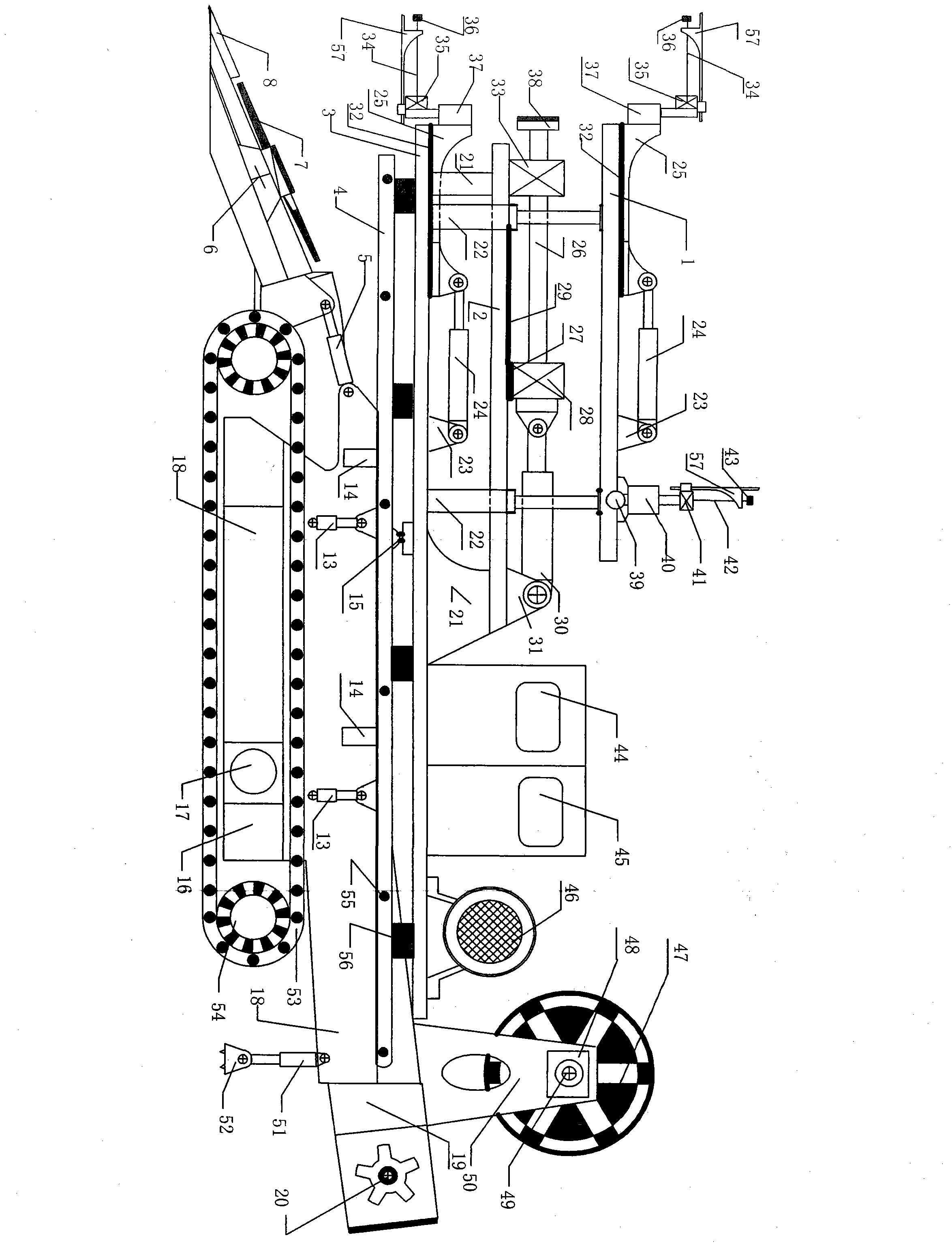

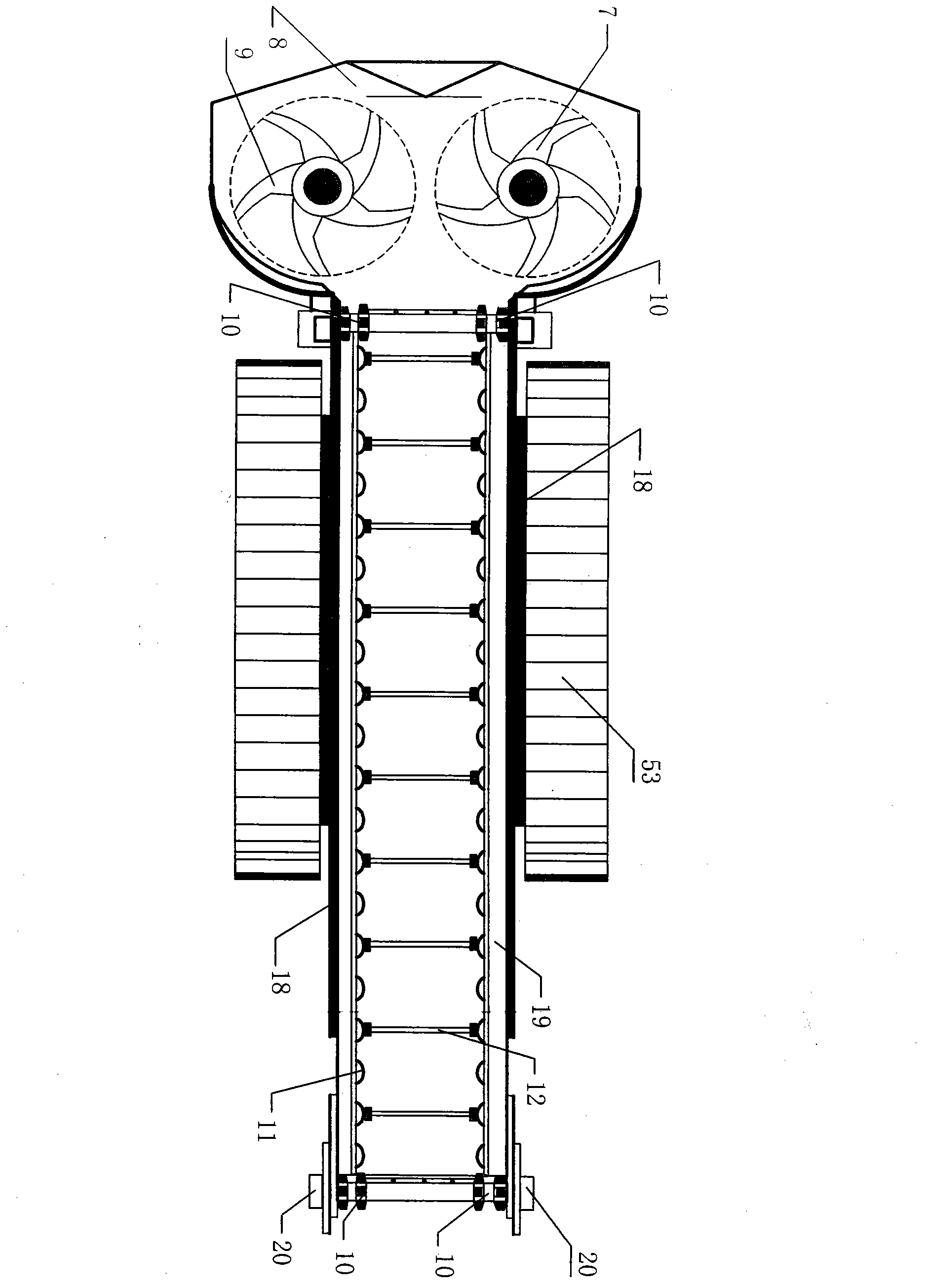

[0057] Such as figure 1 , figure 2 Shown

[0058] The rear supporting cylinders 51 of the main body are vertically installed at the rear on both sides of the main body frame 18 of the main body part, and the rods of the rear supporting cylinder 51 are connected with the rear supporting feet 52.

[0059] The hydraulic motor 17 and the reducer 16 of the walking part are respectively installed on both sides of the lower part of the main body frame 18. The hydraulic motor 17 and the reducer 16 are connected through the output shaft, the reducer 16 and the sprocket 54 are connected through the output shaft, and the sprocket 54 is connected to the crawler. Chain 53 is connected.

[0060] The shovel plate 8 of the loading part has a driving star 7 and a driven star 9 on the upper surface, and two hydraulic motors 6 on the back, which are respectively connected with the driving star 7 and the driven star 9 through output shafts. The two sides of the rear end of the shovel plate 8 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com