Reversible temperature-sensitive cigarette packing paper preparation method

A technology for wrapping paper and cigarettes. It is applied in the fields of cigarette boxes, tipping paper printing, and cigarette paper. It can solve problems such as lattice structure discoloration and achieve the effect of enhancing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

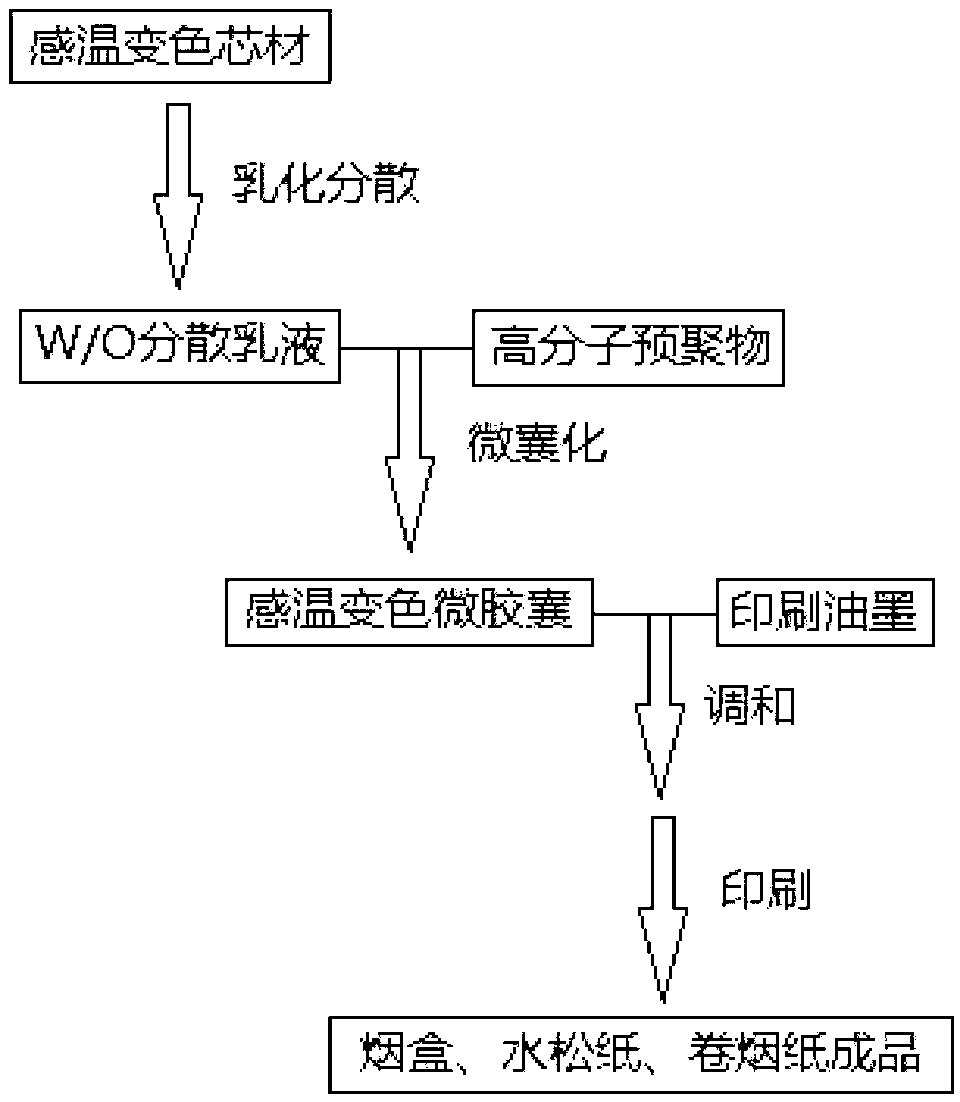

[0033] Such as figure 1 As shown, the steps of the preparation method of the reversible temperature-sensitive cigarette wrapping paper of the present invention are as follows:

[0034] (1) Choose color-changing pigments of inorganic reversible heat-sensitive materials, organic reversible heat-sensitive color-changing compounds, dye leuco color-changing systems, cholesteric liquid crystals, polysilanes or polythiophenes, and use solid-phase methods and liquid-phase methods , Prepared by magnetron sputtering method, chemical vapor deposition method or sol-gel method to obtain a thermochromic core material;

[0035] Among them, the color-changing pigments of inorganic reversible heat-sensitive materials are iodides, complexes, and double salts containing Ag, Cu, and Hg; or compounds formed by copper salts, cobalt salts, and nickel salts hexamethylenetetramine; or metal Solid solution of oxide Cr2O3 in α-Al2O3 / Ga / Ga-La / Y-Al; or vanadate, chromate, tungstate, in which the metal io...

Embodiment 2

[0043] Such as figure 1 The method shown in Example 1 is repeated, and the thermochromic core material is synthesized according to the method described in the above step 1, and then the emulsion is dispersed, and then mixed with the polymer prepolymer shell material at a ratio of 90%, and the microcapsule is carried out. Chemical reaction, after cooling, washing, and drying, temperature-sensitive color-changing microcapsules are obtained; mixed with printing ink in a ratio of 85%, adopting the method described in the above step 4, printing on cigarette wrapping paper, and drying. The thermochromic core material accounts for 20% of the total mass of the thermochromic microcapsules.

Embodiment 3

[0045] Such as figure 1 The method shown in Example 1 is repeated, and the thermochromic core material is synthesized according to the method described in the above step 1, and then the emulsion is dispersed, and then mixed with the polymer prepolymer shell material at a ratio of 70%, and the microcapsule is carried out. Chemical reaction, after cooling, washing, and drying, the temperature-sensitive color-changing microcapsules are obtained; they are mixed with printing ink in a 50% ratio, and the method described in the above step 4 is used to print on cigarette wrapping paper and dry in the air. The thermochromic core material accounts for 95% of the total mass of the thermochromic microcapsules.

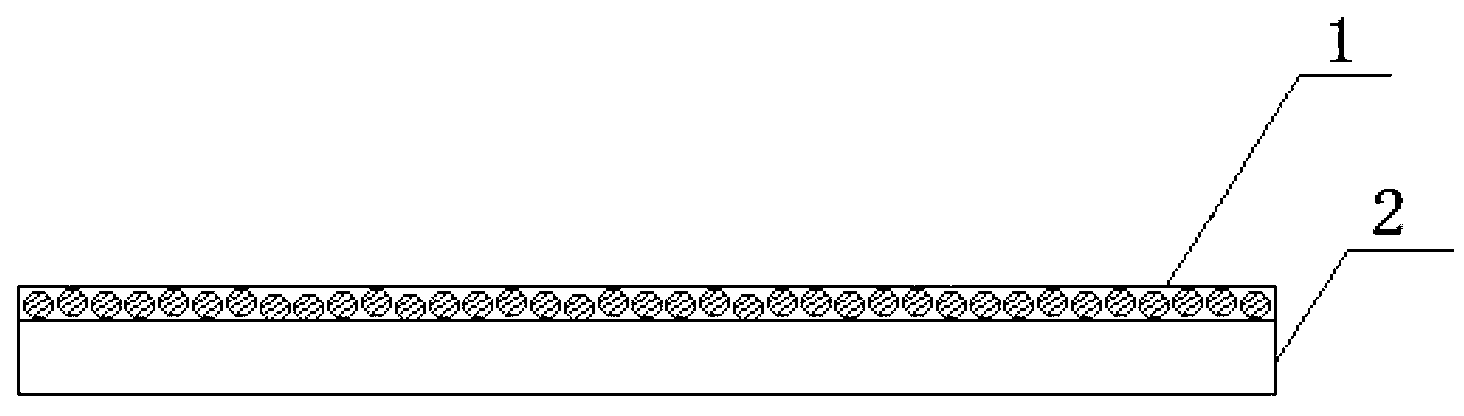

[0046] Such as figure 2 As shown, the schematic diagram of the cigarette structure printed with the reversible thermochromic paint wrapped in microcapsules. The surface of cigarette wrapping paper is coated with microencapsulated temperature-sensitive color-changing dyes, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discoloration temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com