Preparation method of polymer based three-dimensional (3D) biochip

A three-dimensional biological and polymer technology, applied in the direction of combinatorial chemistry, library creation, chemical library, etc., can solve the problems of easy diffusion of microarray points, strong instrument dependence, low fluorescence intensity, etc., to achieve the advantages of activity and stability, Overcoming the effect of being easily destroyed and increasing the fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The LDPE membrane was extracted with acetone (extraction and washing solution) for 72 hours, and dried at room temperature. Cover the BOPP film above the LDPE film, inject 150 μL of isopropylthioxanthone acetone solution (concentration: 0.3M) between the double-layer polymers, and then use two quartz plates to compact the double-layer polymers. Propylthioxanthone acetone solution is evenly distributed between the double-layer polymers to form a sandwich structure, and moved into a high-pressure mercury lamp irradiation device (power 1000W, light intensity 10mW / cm 2 ) at room temperature for 180 seconds. The LDPE film that has introduced dormant groups that can continue to initiate free radical polymerization was extracted with acetone for 12 hours to remove isopropylthioxanthone adsorbed on the surface, and dried in a vacuum oven at 25° C. for 2 hours.

[0024] Drop 150 μL of methoxypolyethylene glycol methacrylate solution (monomer molecular weight 1100, solution conc...

Embodiment 2

[0032] Preparation of UV-Vis Spectrophotometric Standard Curve:

[0033] First prepare 1mg / mL BSA stock solution, and then dilute to different concentrations with PBS solution. A total of 9 groups, the concentrations are 0μg / mL, 100μg / mL, 200μg / mL, 400μg / mL, 500μg / mL, 600μg / mL, 800μg / mL, 900μg / mL, 1000μg / mL. The solution with a concentration of 0 μg / mL is the calibration zero solution.

[0034] After the ultraviolet-visible spectrometer is calibrated and reset to zero, take solutions of different concentrations, put 1mL in a cuvette, and scan the absorption at 278nm at a fixed point, that is, A278. The results were repeated 3 times and the average value was taken.

[0035] Use the obtained A278 value to plot with origin and fit it to obtain a standard curve A=(6.31475E-4)c – 0.01853.

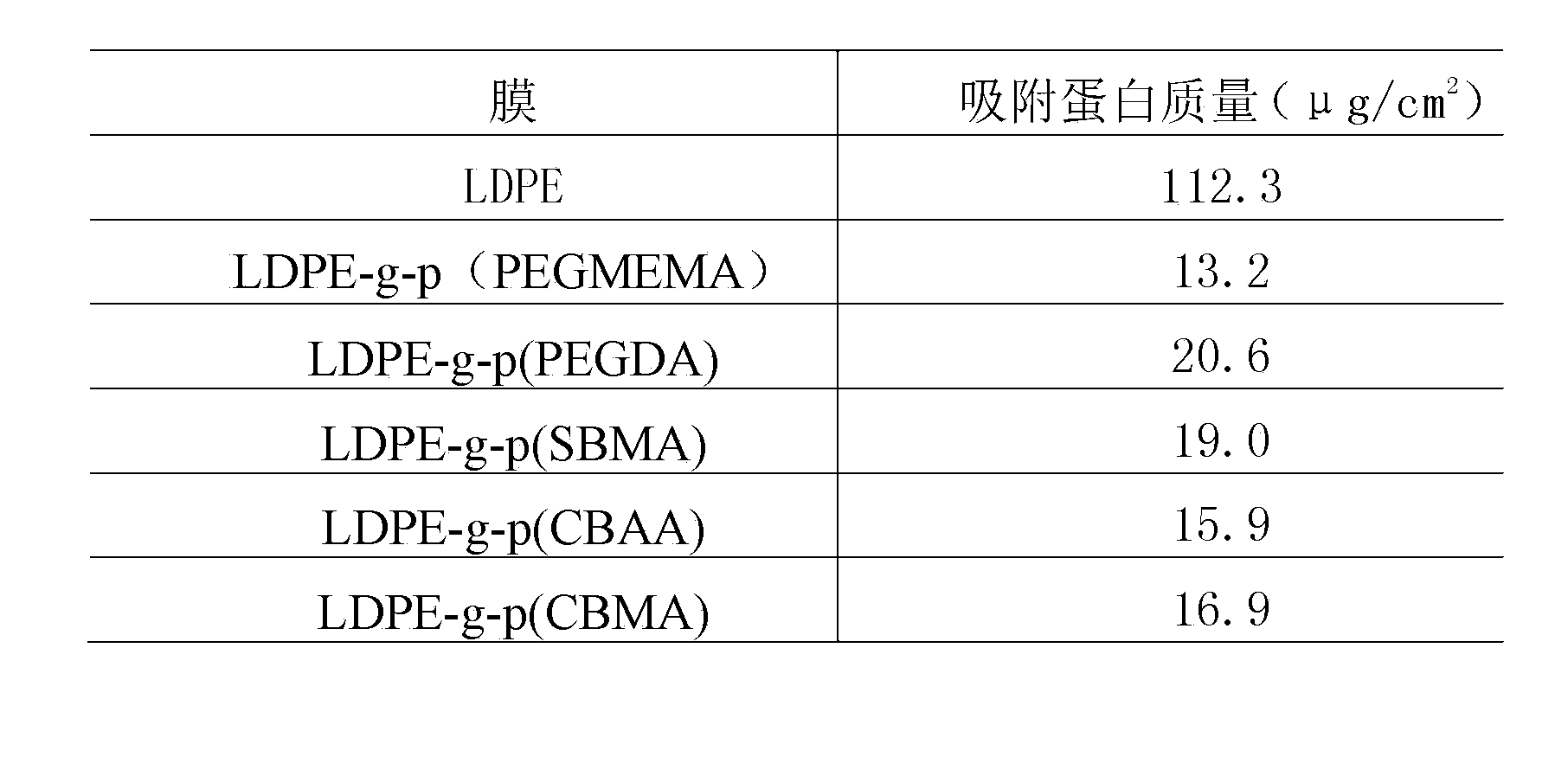

[0036] Anti-biofouling performance test before and after grafting of different anti-biofouling monomers:

[0037] Respectively set the size to 9cm 2 1 sheet of LDPE (No. 1), 1 sheet of LDPE...

Embodiment 3

[0045] The PET film was extracted with acetone (extraction and washing solution) for 72 hours, and dried in a vacuum oven at 25°C for 2 hours. Cover the BOPP film above the PET film, inject 150 μL of benzophenone in acetone solution (concentration: 0.3M) between the double-layer polymers, and then use two quartz plates to compact the double-layer polymers, benzophenone The acetone solution is evenly distributed between the double-layer polymers to form a sandwich structure, and moved into the high-pressure mercury lamp irradiation device (power 1000W, light intensity 16mW / cm 2 ) at room temperature for 180 seconds. The PET film into which the polymerized dormant groups had been introduced was extracted with acetone for 12 hours to remove benzophenone adsorbed on the surface, and dried in a vacuum oven at 25° C. for 2 hours.

[0046] Drop 150 μL of methoxypolyethylene glycol methacrylate solution (monomer molecular weight 1100, solution concentration 0.3M) between the BOPP fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com