Method for accelerating solid-liquid separation of nanometer particle suspension

A nanoparticle and solid-liquid separation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of nanomaterials that are difficult to settle, affect the quality of effluent water, and low separation efficiency, so as to reduce the turbidity of effluent water, ensure the quality of effluent water, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Access to N 2 Under these conditions, iron nanoparticles were mixed with deionized water, APAM and NPAM with a molecular weight of about 4 million to 5 million in three beakers, and the reaction concentrations of iron nanoparticles, APAM and NPAM were 2 g / L and 0.02 g / L. L, 0.02 g / L, with a G value of 800 s -1 Stir for 20 s, then use G value for 50 s -1 Stir for 5 min. After the stirring is completed, take 50 mL of the mixture in three 50 mL graduated cylinders and let it settle for 20 min. The results showed (Table 1) that after 1 h of reaction, the turbidity of the effluent without flocculant PAM was 21 times and 13 times higher than that of NPAM and APAM respectively.

[0026] Table 1. Comparison of sedimentation effect and supernatant turbidity in three groups of experiments in Example 1

[0027]

Embodiment 2

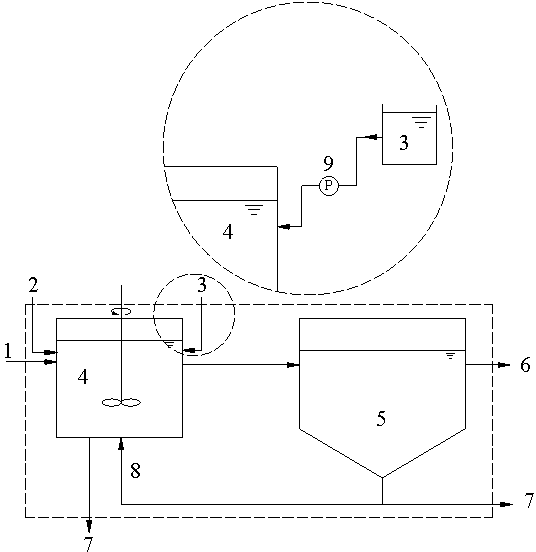

[0029] Such as figure 2 As shown in the process flow, feed water 1 and nanometer zero-valent iron 2 enter the reaction zone 4 from the same side of the reaction zone 4, and PAM is added to the upper part of the reaction zone 4 through a metering pump; the outlet of the other side of the reaction zone 4 is connected to the precipitation zone 5 One side of the sedimentation zone 5 is the water outlet 6; the bottom of the reaction zone 4 is the outlet of the remaining sludge 7, part of the sludge at the bottom of the sedimentation zone 5 returns the return sludge 8 to the bottom of the reaction zone 4 through the pipeline, and the other part of the sludge at the bottom of the sedimentation zone 5 Mud connects the remaining sludge 7 outlets. The continuous flow test was carried out in the small test device of the closed continuous nano-iron particle reactor. The nano-iron particles reacted with the copper smelting wastewater of a factory in the reaction zone. The concentration of...

Embodiment 3

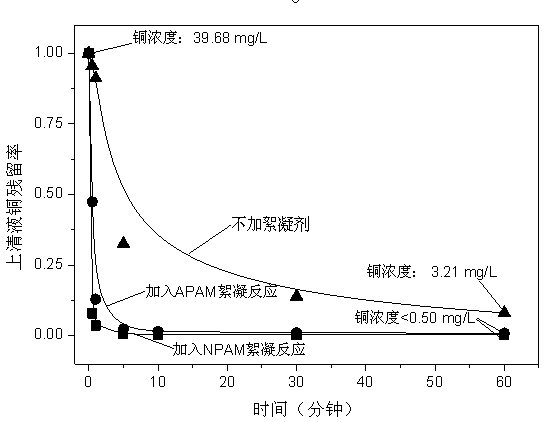

[0031] Access to N 2 Under the conditions, the nano-iron particles were reacted with a copper mine smelting wastewater in a conical flask. The concentration of copper ions in the wastewater was 50 mg / L, the concentration of nano-iron particles was 500 mg / L, and the G value was 80 s -1 . After reacting for one hour, take 50ml of the mixed solution in three beakers, and then add a small amount of equal volume of APAM solution, NPAM solution and deionized water respectively. The reaction concentrations of APAM and NPAM are both 5 mg / L. In access N 2 Under the condition, the G value is 800 s -1 Stir for 20 s, then set at a G value of 800 s -1 Stir for 5 min. After the stirring is completed, take 50 mL of the mixture in three 50 mL graduated cylinders and let it settle for 20 min. The supernatant was taken at the same height at the same interval, and the copper concentration in it was measured with an inductively coupled plasma emission spectrometer (ICP-Agilent720ES). The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com