Silicon microstructure processing method based on femtosecond laser treatment and wet etching

A technology of femtosecond laser and wet etching, which is applied in the processing of silicon microstructure, deep silicon groove processing based on femtosecond laser processing and wet etching, can solve the problems of complicated process and achieve simple process and deep Large, good corrosion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the processing of deep silicon grooves is taken as an example, and the details are as follows:

[0036] Raw material: N-type monocrystalline silicon wafer polished on one side, crystal orientation, thickness 500μm.

[0037] The detailed implementation of the preparation steps of high aspect ratio deep silicon grooves is described as follows:

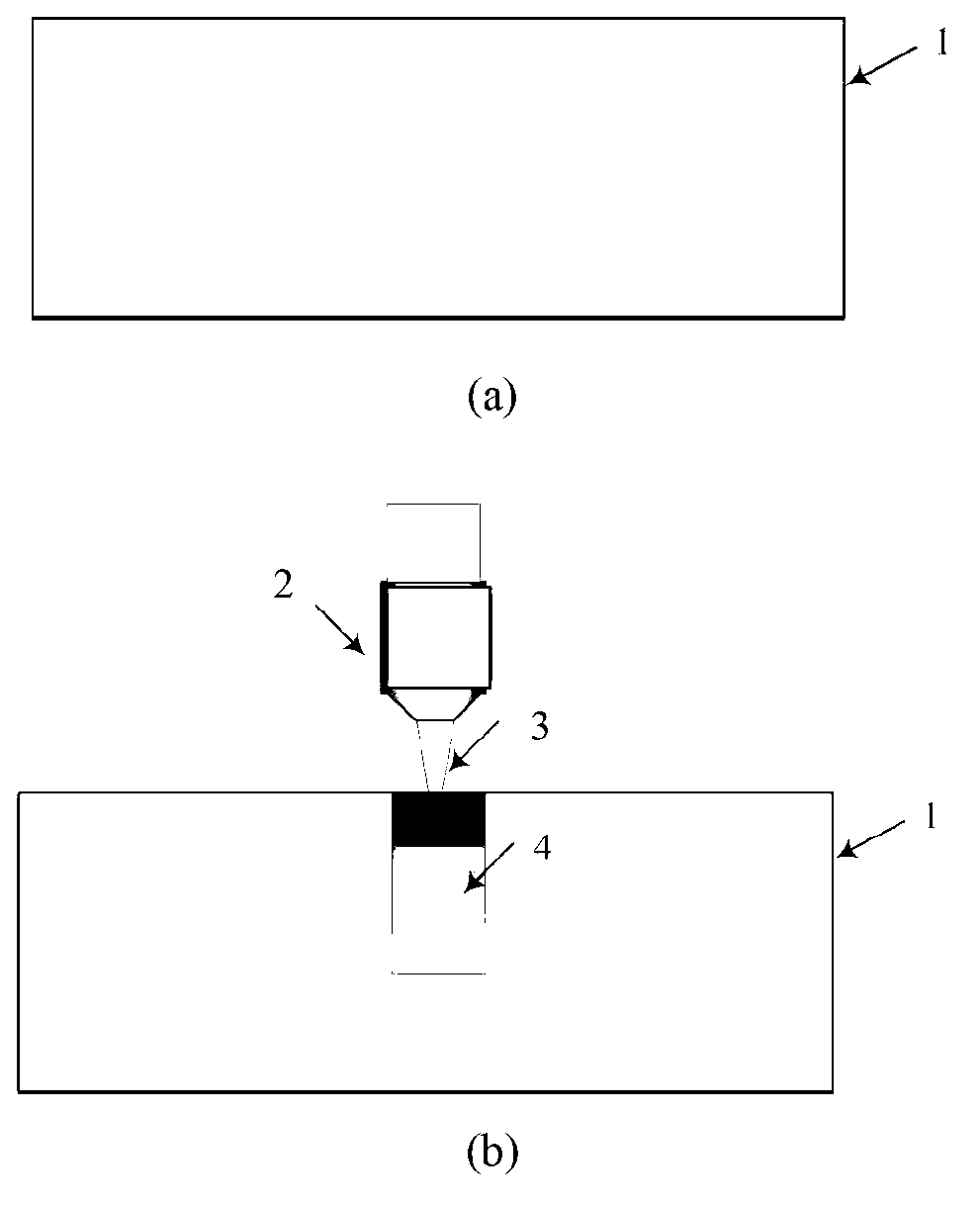

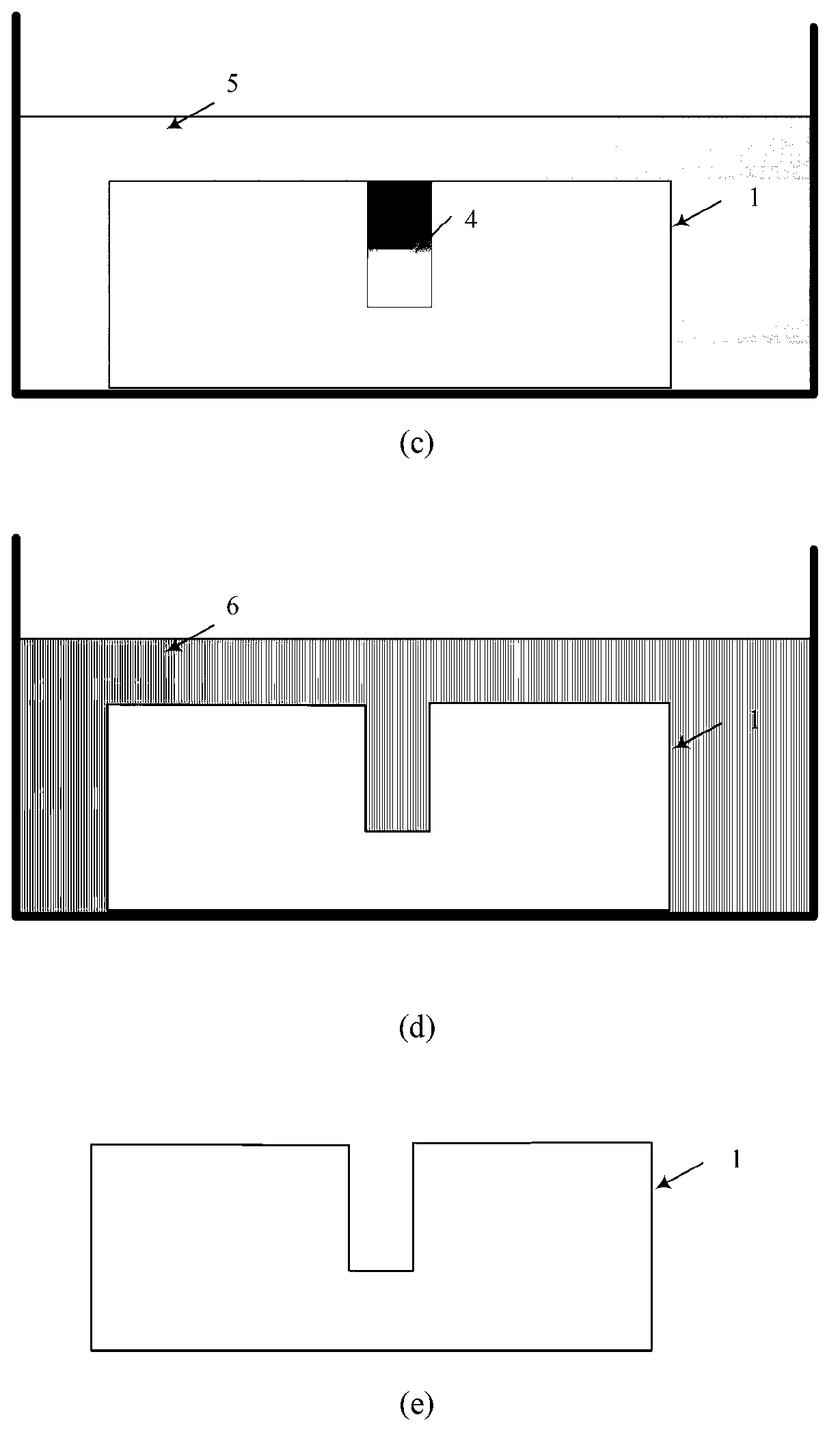

[0038] (1) Use acetone, alcohol and deionized water to carry out ultrasonic-assisted cleaning on the single crystal silicon substrate 1 in sequence, and dry it after cleaning, see figure 2 (a).

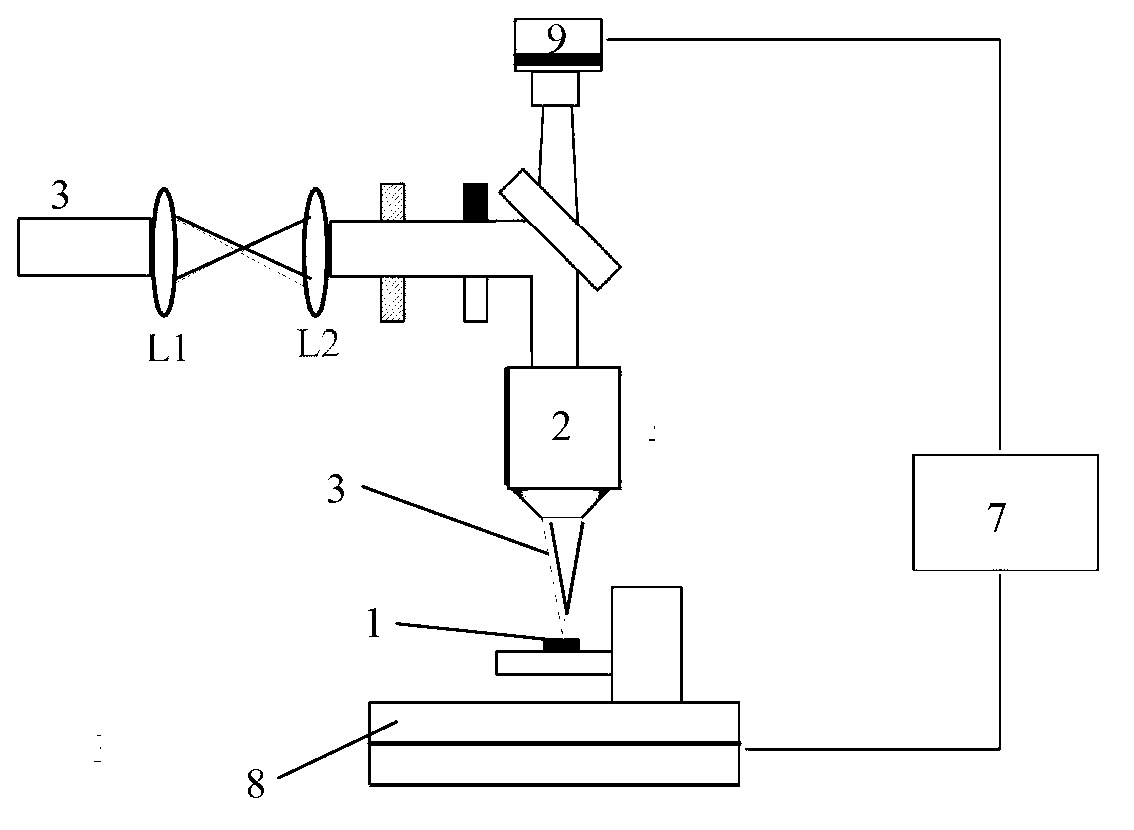

[0039] (2) The pulse width of the femtosecond laser 3 is 50 fs, and the power is set to 30 mW. A microscopic objective lens 2 with a value of 10× and a numerical aperture of 0.3 is selected to focus the femtosecond laser 3 on the single crystal silicon substrate 1 through the microscopic objective lens 2, and the scanning speed of the three-dimensional electric translation stage 8 is 2 μm / s. Use the femtosecond la...

Embodiment 2

[0043] Raw material: N-type monocrystalline silicon wafer polished on one side, crystal orientation, thickness 500μm.

[0044] (1) Cleaning of the single crystal silicon substrate 1 refers to the corresponding process of the first embodiment.

[0045] (2) The process of scanning the monocrystalline silicon substrate 1 with the femtosecond laser 3 refers to the corresponding process of Example 1, and the parameters are: the pulse width of the femtosecond laser 3 is 50 fs, and the power is set to 30 mW; A microscope objective lens 2; a three-dimensional electric translation stage 8 with a scanning rate of 2 μm / s.

[0046] (3) Corrosion of silicon wafer after scanning by femtosecond laser 3 Refer to the corresponding process of Example 1.

[0047](4) Cleaning of the silicon wafer after etching refers to the corresponding process of Example 1.

[0048] Figure 4 It is the morphology of the silicon groove finally processed in Example 2. It can be seen from the figure that the ...

Embodiment 3

[0050] Raw material: N-type monocrystalline silicon wafer polished on one side, crystal orientation, thickness 500μm.

[0051] (1) Cleaning of the single crystal silicon substrate 1 refers to the corresponding process of the first embodiment.

[0052] (2) The process of scanning the monocrystalline silicon substrate 1 with the femtosecond laser 3 refers to the corresponding process of Example 1, and the parameters are: the pulse width of the femtosecond laser 3 is 50 fs, and the power is set to 40 mW; select 10 ×, numerical aperture 0.3 A microscope objective lens 2; a three-dimensional electric translation stage 8 with a scanning rate of 2 μm / s.

[0053] (3) Corrosion of silicon wafer after scanning by femtosecond laser 3 Refer to the corresponding process of Example 1.

[0054] (4) Cleaning of the silicon wafer after etching refers to the corresponding process of Example 1.

[0055] Figure 5 It is the morphology of the silicon groove finally processed in Example 3. As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com