Supply system for sub-cooling and nano particle jet flow minimal quantity lubrication coupled grinding medium

A technology of micro-lubrication and supply system, applied in grinding/polishing equipment, grinding/polishing safety device, metal processing equipment, etc. It can solve the problem of not establishing convection and heat transfer in the grinding zone, and not establishing the mechanism of oil film formation on the surface of the workpiece. , Unable to exert the advantages of grinding wheel/workpiece interface lubrication and heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention is described:

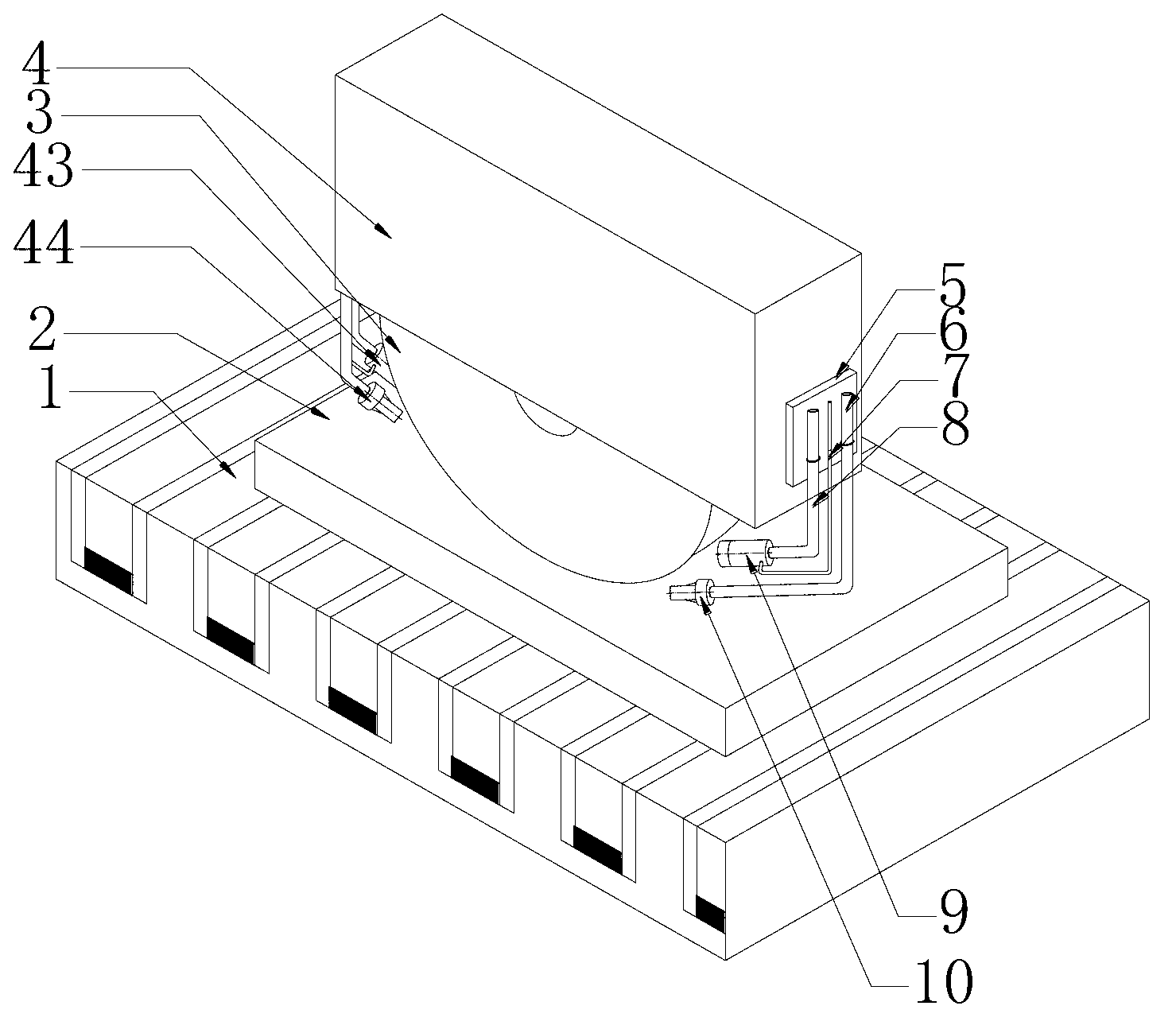

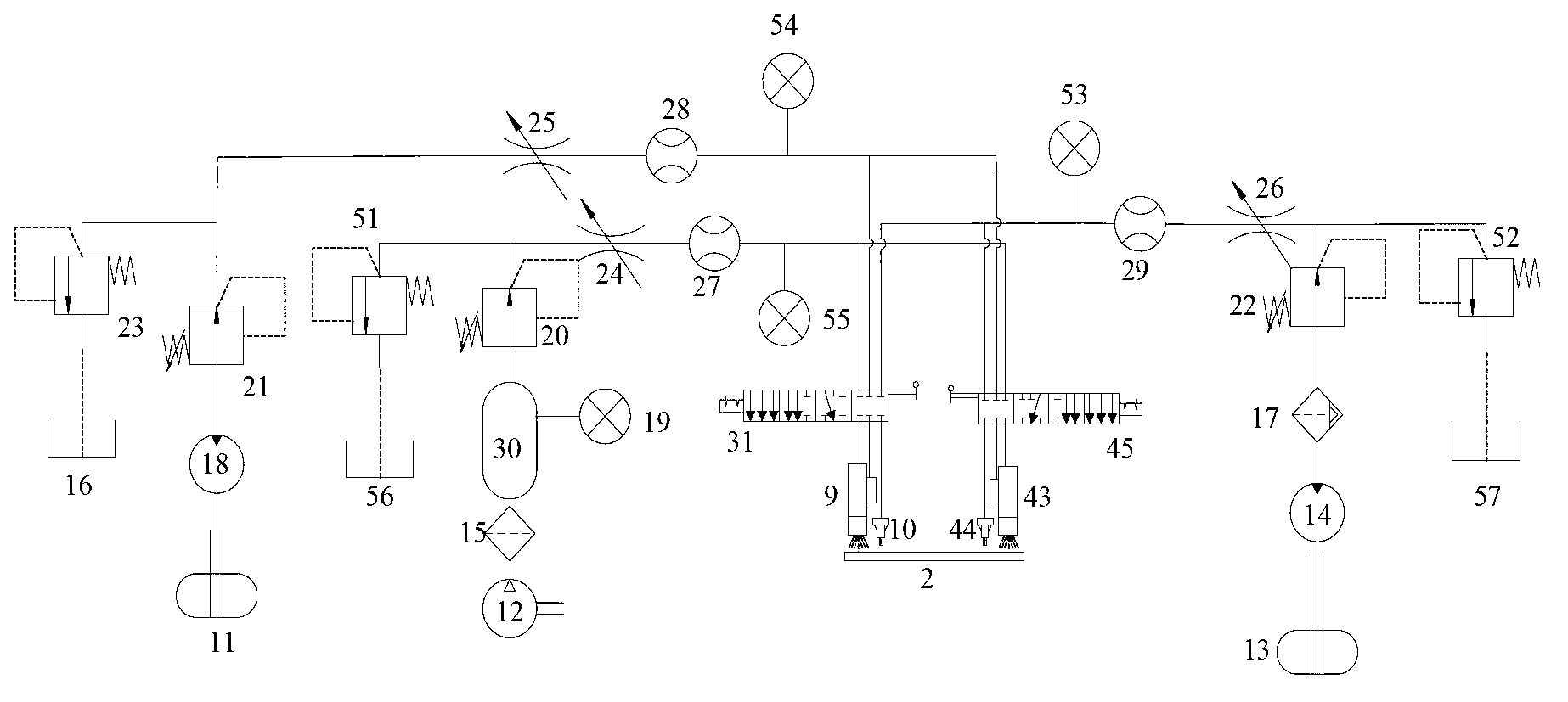

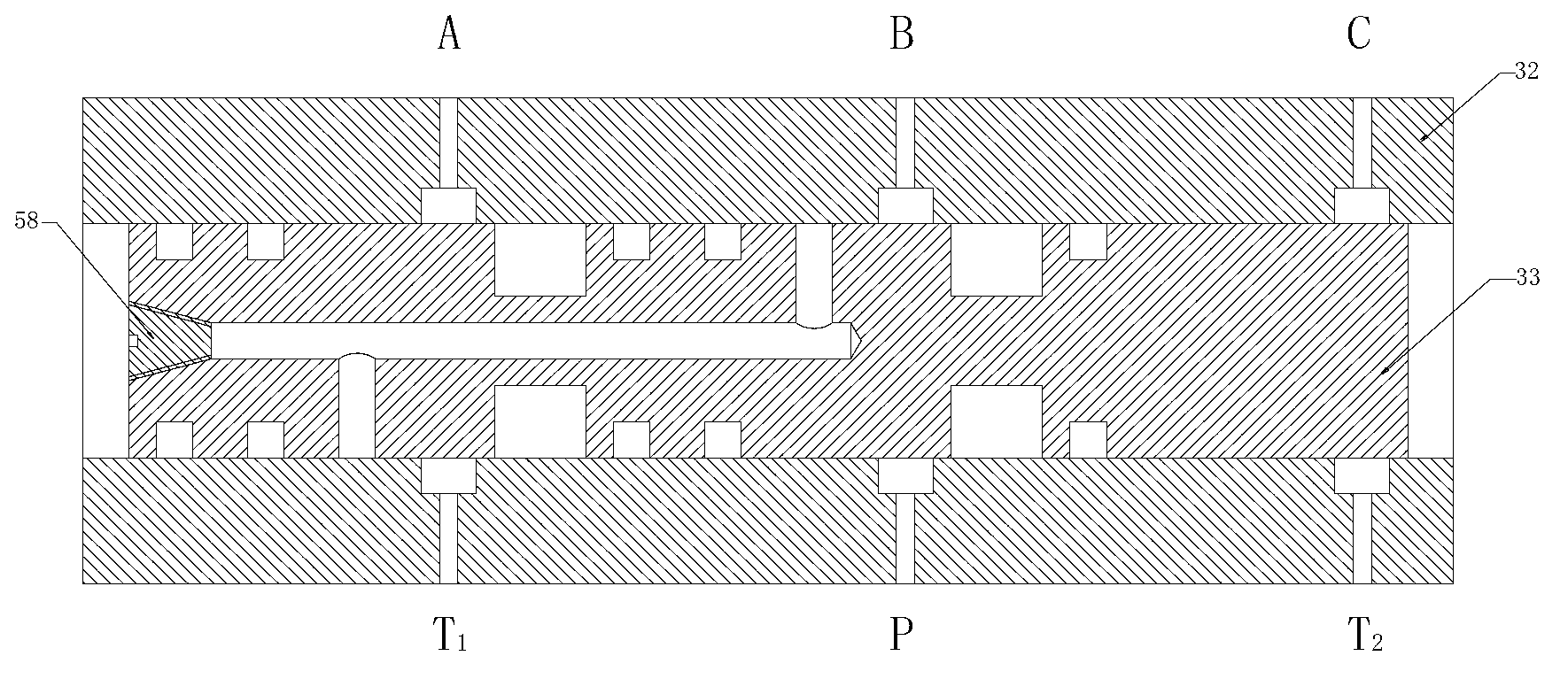

[0055] From figure 1 It can be seen from the figure that there are two sets of nozzles in this embodiment, which are the micro-lubrication atomizing nozzle I9 and the low-temperature cooling nozzle I10 on the right side of the grinding wheel, and the micro-lubrication atomizing nozzle II43 and the low-temperature cooling nozzle II44 on the left side of the grinding wheel. The minimal quantity lubrication atomizing nozzle I9 is connected with the nanofluid delivery pipe 7 and the compressed air delivery pipe 8 , and the low-temperature cooling nozzle I10 is connected with the low-temperature medium delivery pipe 6 . The minimal quantity lubrication atomizing nozzle II43 and the low-temperature cooling nozzle II44 are also connected to the delivery pipe on the other side. The magnetic fixed suction cup 5 is adsorbed on the side of the grinding wheel 3 and is used to fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com