Manufacturing technology of R4 grade mooring cable used on deep sea drilling platform

A drilling platform and production process technology, applied in the field of R4 mooring chain production process for deep-sea drilling platforms, can solve problems such as increasing energy consumption, reducing production efficiency, tempering cracks, etc. The effect of energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

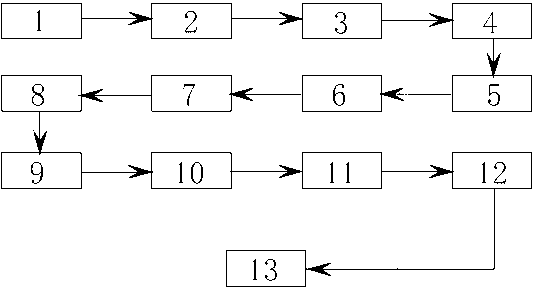

Image

Examples

Embodiment Construction

[0027] Specific steps are as follows:

[0028] 1. Blanking: According to the production notice, the sawing machine is transferred according to the process documents for cutting, and self-inspection and random inspection are carried out. The qualified materials are placed on the material rack and counted, and sent to the intermediate frequency furnace for heating;

[0029] 2. Heating: adjust the heating power and furnace hall according to the specifications and models, and carry out continuous production to ensure that the hot rod material is at about 800°C, and send the hot rod material into the ring weaving machine;

[0030] 3. Ring weaving: adjust the tire mold of the equipment according to the process requirements, weave the heated bars into chain rings, and meet the process requirements, and then send them to the welding machine by the rotary machine;

[0031] 4. Flash welding: Adjust the welding parameters and transformer gear according to the process requirements, weld t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com