Connecting method for aluminum-steel dissimilar materials

A technology of dissimilar materials and connection methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reducing the stability of the welding process, failure of welded joints, reducing the bonding of aluminum-steel interfaces, etc., to achieve the suppression of brittle intermetallic compounds , Low welding heat input, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

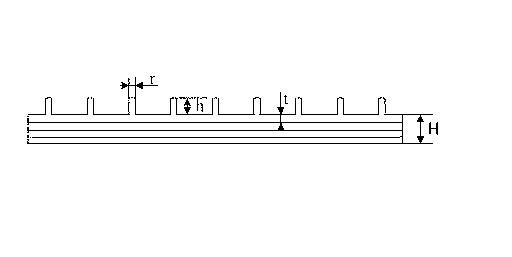

[0020] As shown in the figure, a method for connecting dissimilar materials of aluminum and steel, through CMT power supply and numerical control programming, realizes the stacking of three kinds of welding wires of steel, nickel and aluminum according to a specific walking path, and finally produces steel parts 1, nickel-based alloy metal Aluminum-steel transition joint composed of layer 2 and aluminum part 3, aluminum part 3 can be pure aluminum or aluminum alloy material, steel part 1 includes non-alloy steel or austenitic stainless steel or martensitic with carbon content less than 0.25% Stainless steel or duplex stainless steel, including the following steps:

[0021] Step 1. Clean the contact surface of the parts to be welded and within 30 mm around them by mechanical means, such as using electric wire brushes, emery cloths, etc. The parts to be welded can be pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com