Device and method for quickly fabricating electrode

An electrode and rapid technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of complex manufacturing of special electrodes, and achieve the effects of low cost, omitting complex processes, and high molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

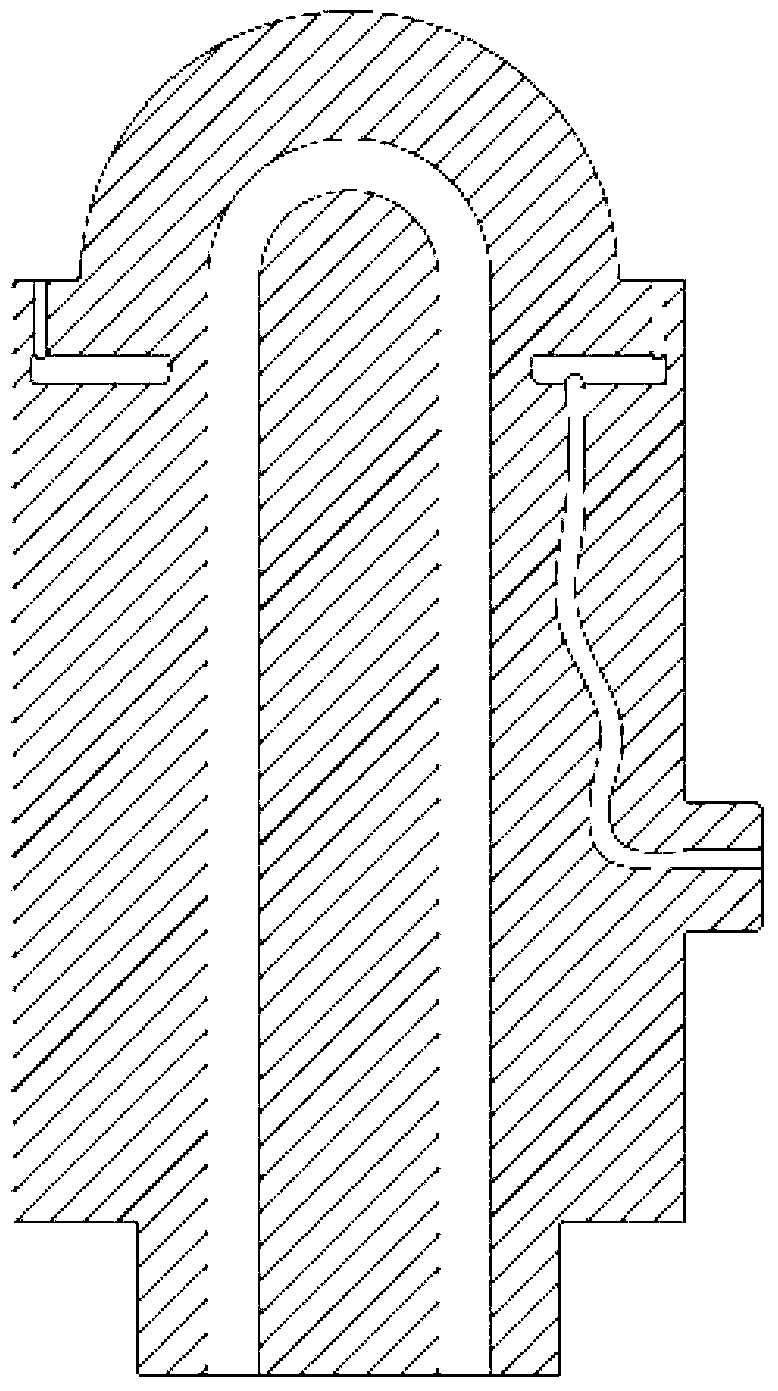

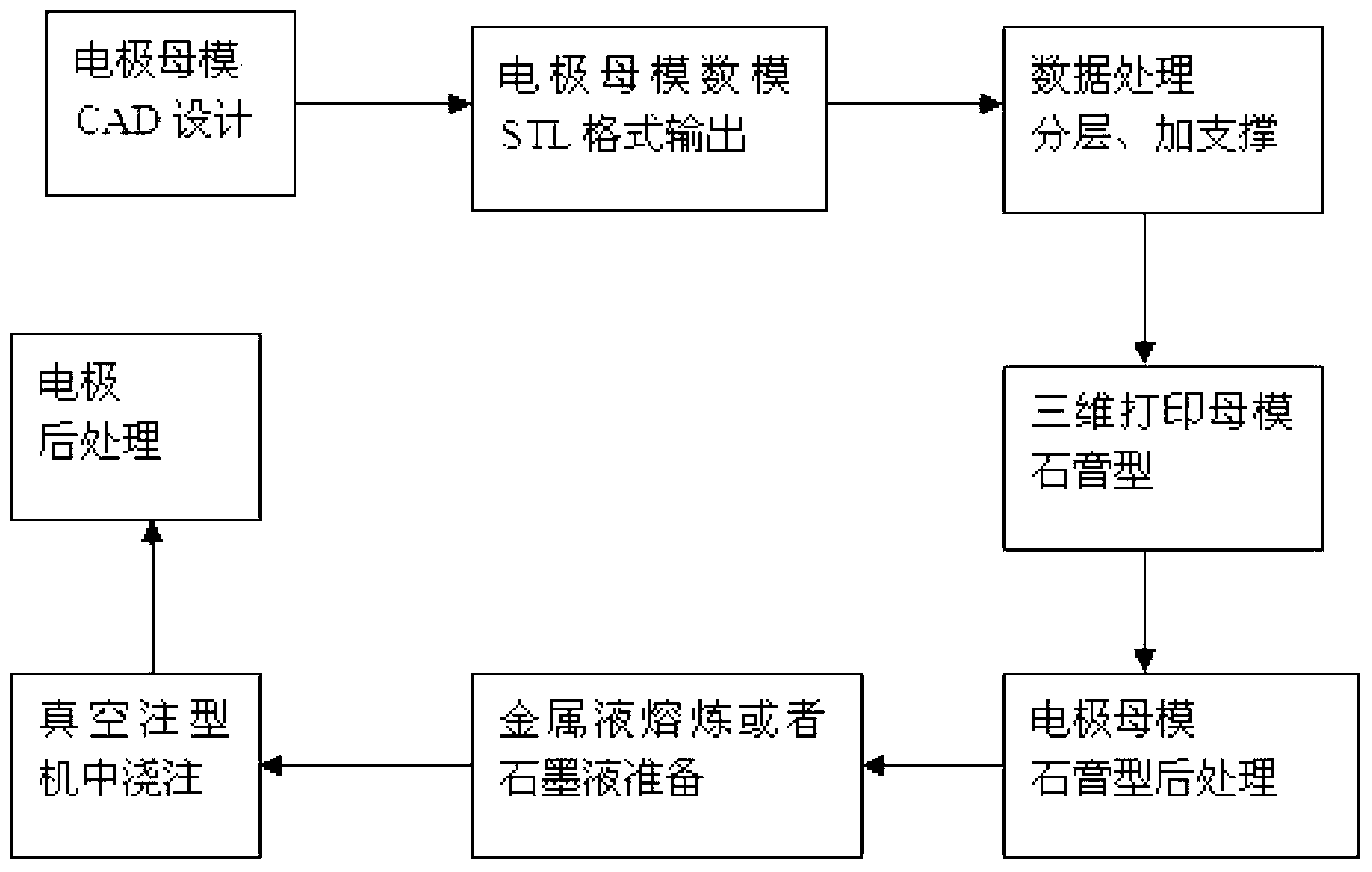

[0027] Such as Figure 1 ~ Figure 3 As shown, the electrode size of the embodiment is small, and the external dimensions: the length is less than 100, the width and thickness are less than 50, the material is copper alloy, and there are cooling water cooling channels and gas channels inside. It is generally made into a combined structure, and it is difficult to shape the internal structure, requiring special processing.

[0028] A device for rapidly making electrodes, including a master mold body 1, a pouring system 2, an electrode cavity 3, a cooling channel forming mold 4, an air outlet forming mold 5, an air passage forming mold 6, an air inlet joint forming mold 7, and a gate 8. Base 9. The lower part of the master mold body 1 is the base 9. The base 9 communicates with the gating system 2. The top of the gating system 2 is a gate 8 in the shape of a bell mouth. The master mold body 1 and the base 9 form a cavity. The body is an electrode cavity 3, the upper part of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com