Patterned substrate and stacked light emitting diode

A light-emitting diode, patterned technology, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will pass Figure 1-Figure 27 To illustrate the fabrication of stacked LED structures according to various embodiments of the present invention.

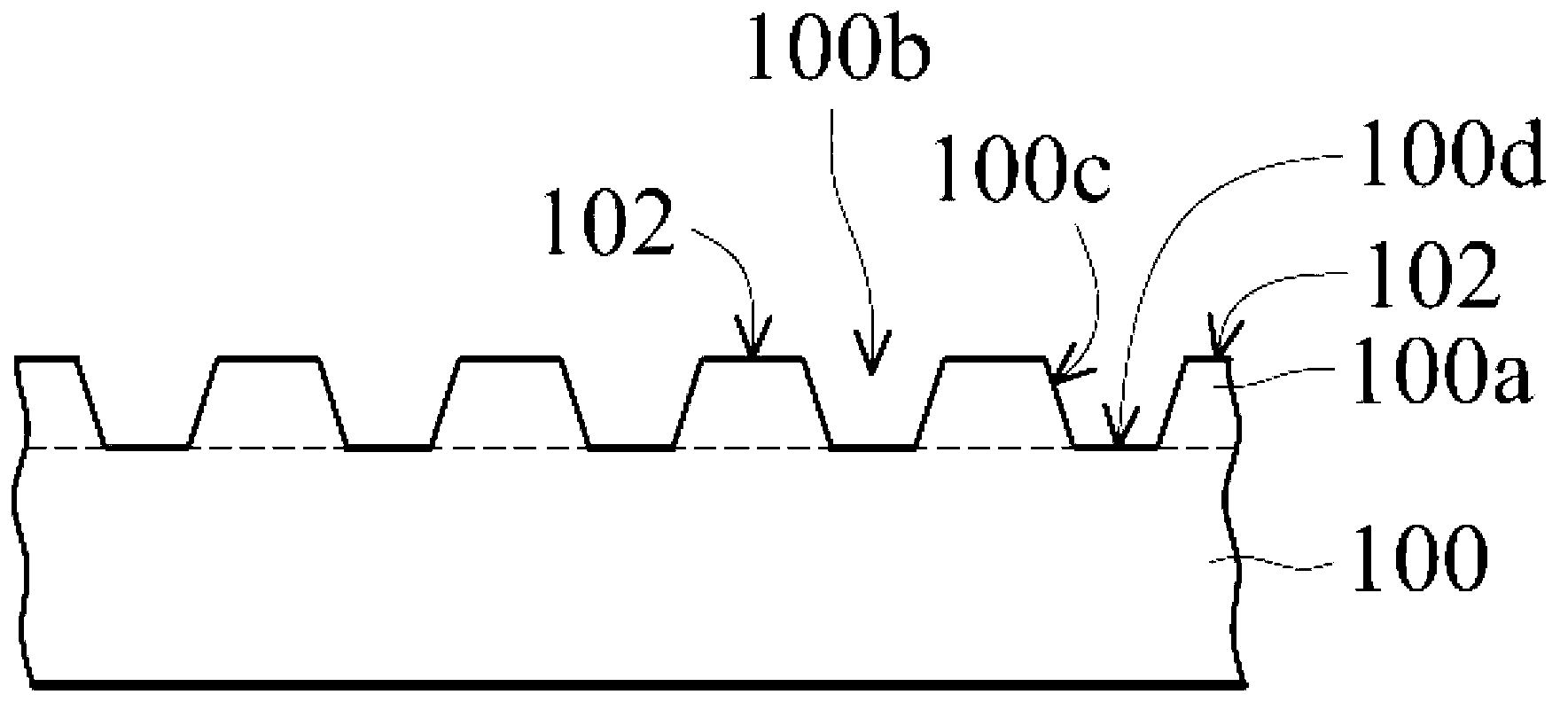

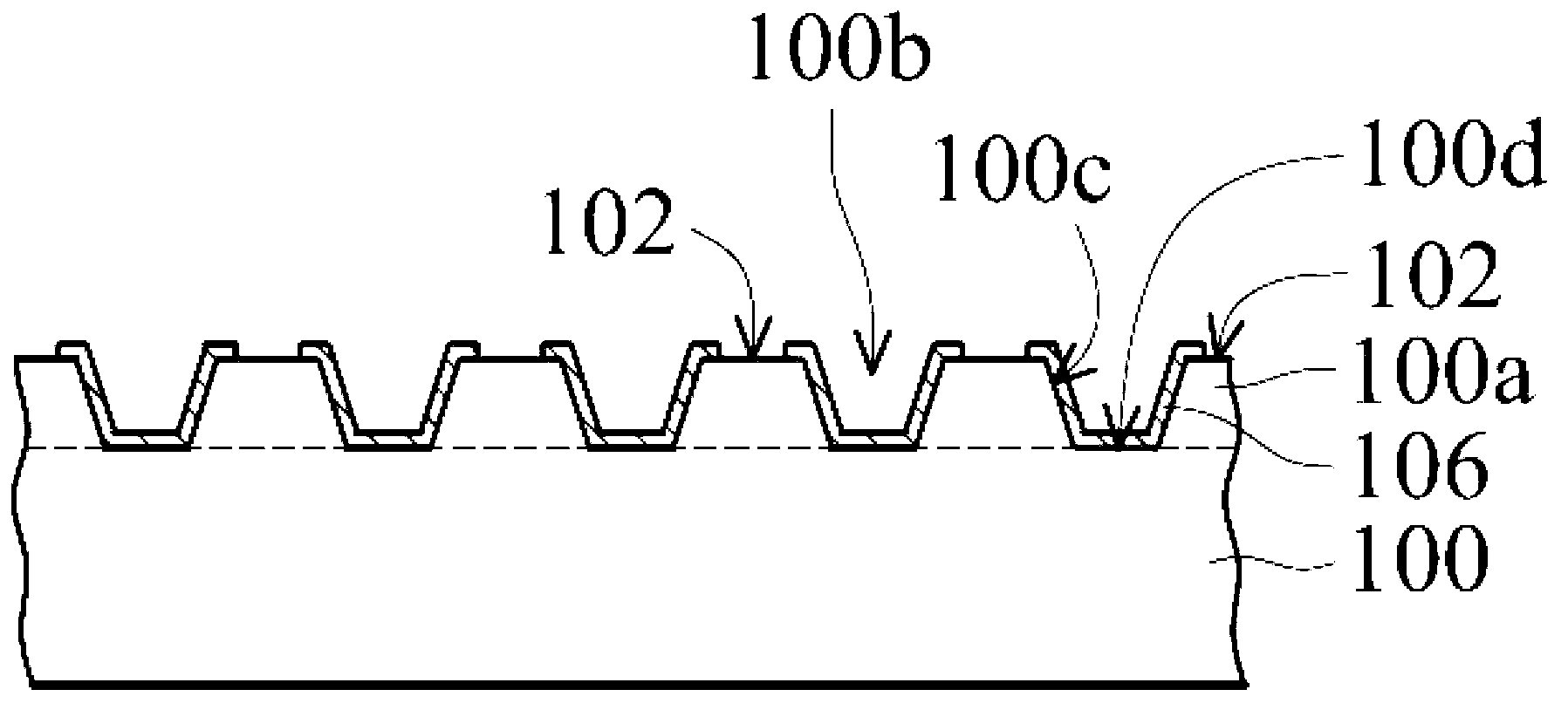

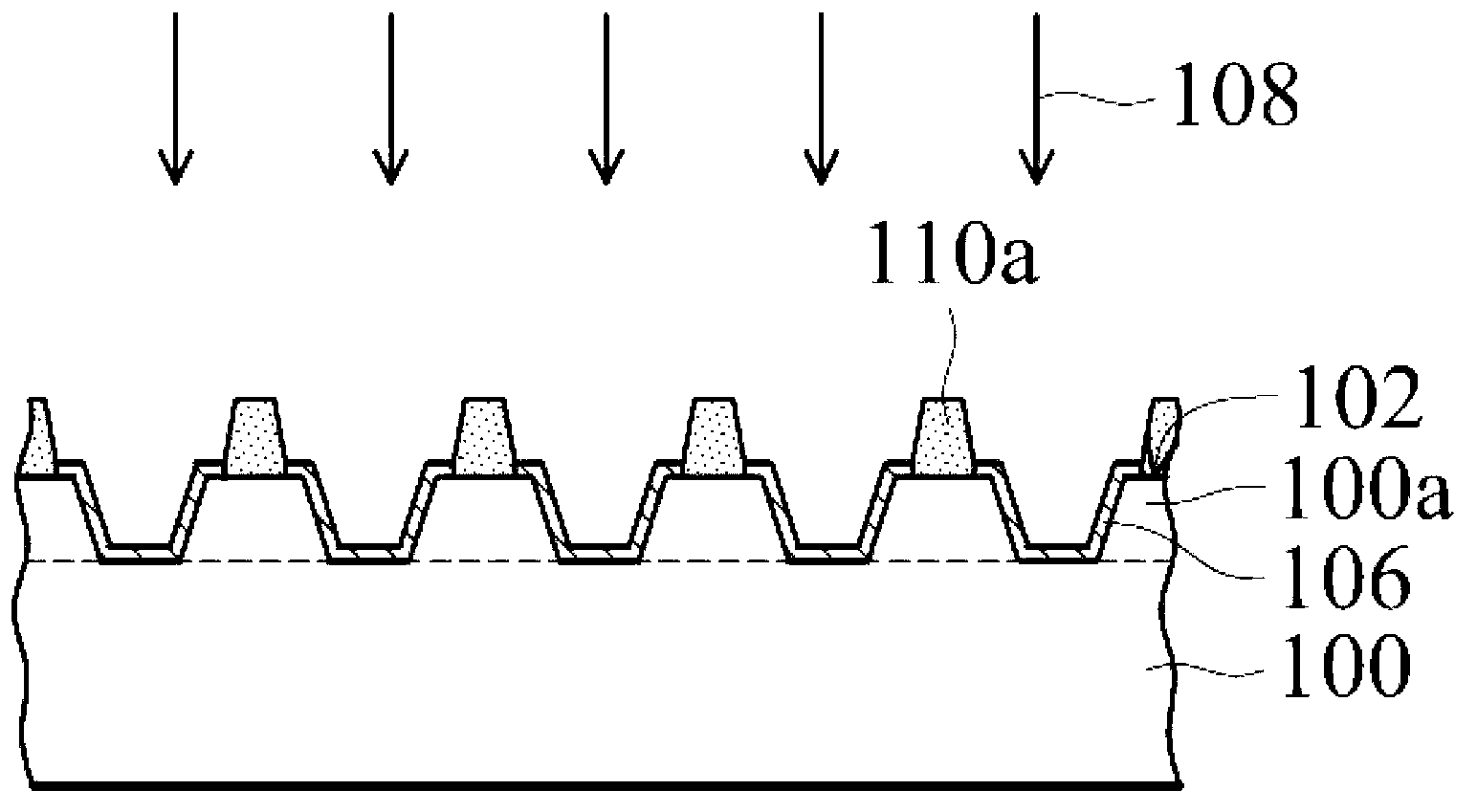

[0039] Figure 1-Figure 5 It is a schematic diagram of fabrication of a stacked LED structure according to an embodiment of the present invention. Please refer to figure 1 Firstly, a substrate 100 with a flat surface is provided, such as a sapphire substrate, which has a top surface 102, which is essentially a flat surface. The substrate 100 may include materials such as sapphire, silicon, and silicon carbide. Next, through the application of a suitable patterned mask (not shown), using lithography to define the etching area, and then performing an etching process (not shown) to partially remove portions of the substrate 100 from the top surface 102, and then forming on the substrate 100 A plurality of separated islands 100a. The separated islands 100a define a plurality of spaced apart recessed structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com