Rough-fine-movement laminated workbench with laser interferometer measurement

A technology of laser interferometer and workbench, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of not being able to meet the high speed, large load and high dynamic characteristics of lithography equipment, and not being able to adapt to the dual-station switching system, Problems such as poor structural integrity, to achieve the effect of compact structure, reducing the number of parts, and reducing the requirements for high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

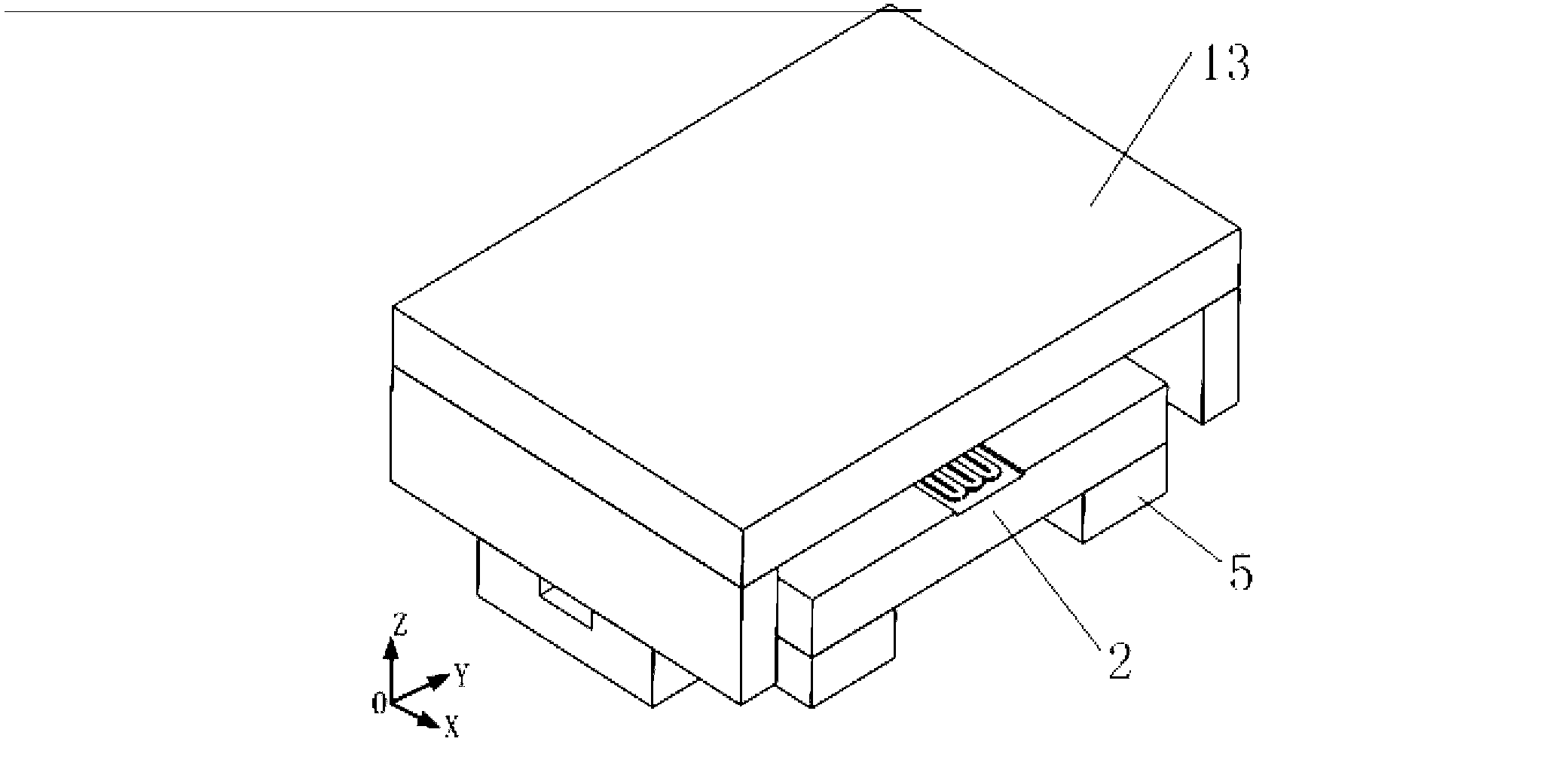

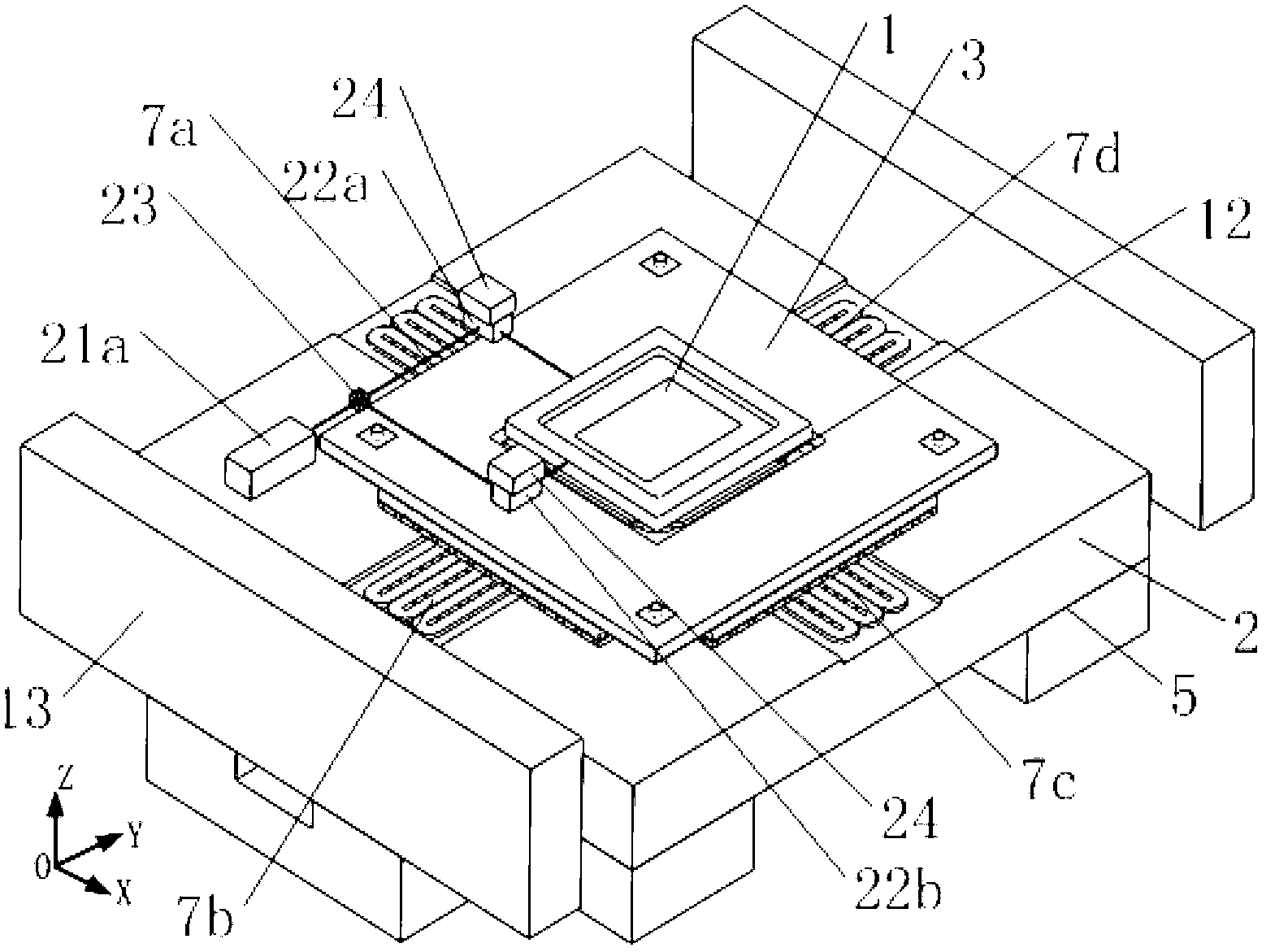

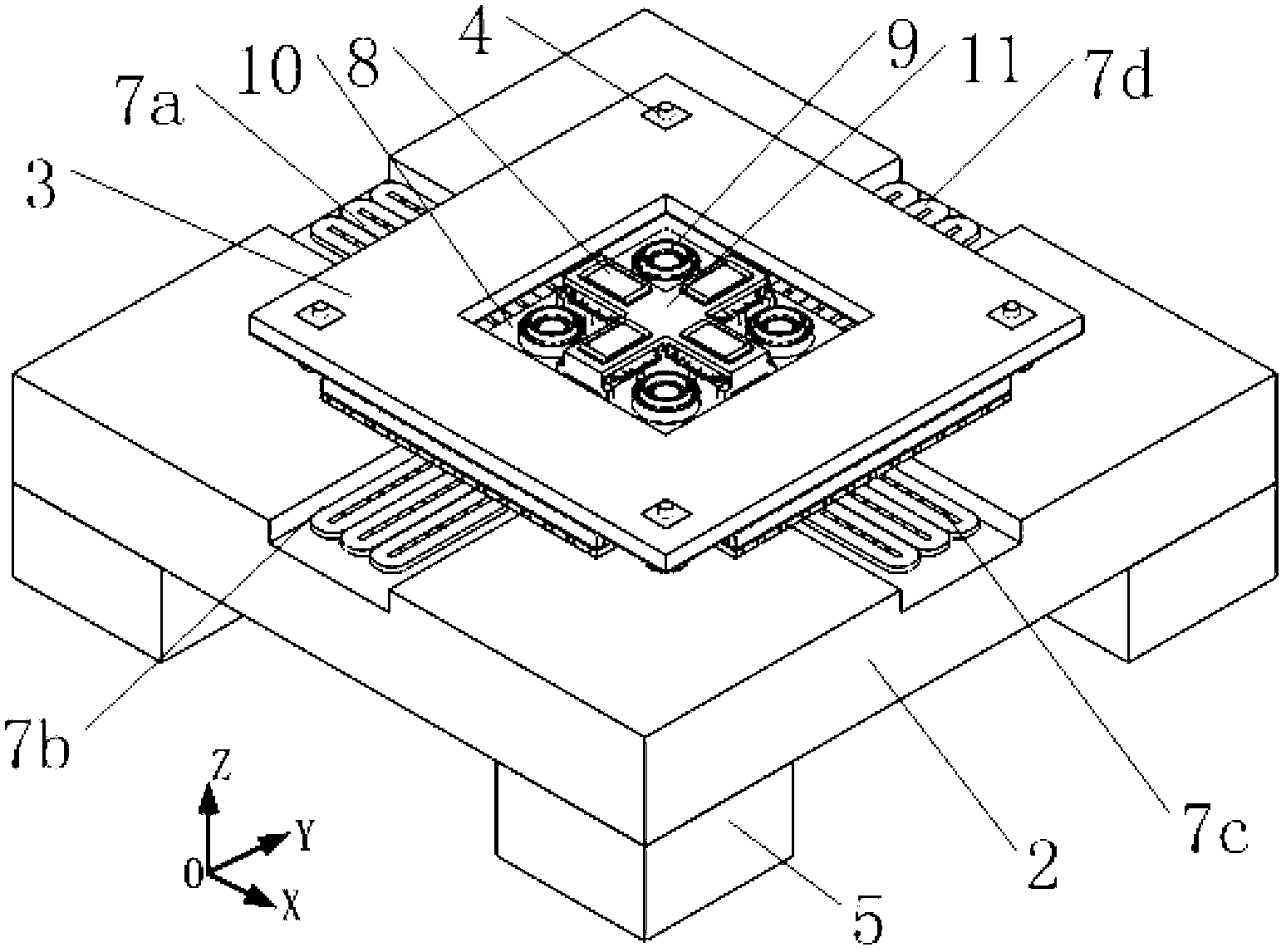

[0024] figure 1It is a three-dimensional structure diagram of a coarse-fine motion lamination workbench with laser interferometer measurement provided by the present invention. The workbench contains a fine motion table, a coarse motion table, a balance weight 2, a vibration isolator 5 and a measuring frame 13. The fine motion table and the coarse motion table are stacked on the upper surface of the balance weight, and the fine motion table is composed of a supporting piece table 1, a fine motion table mover frame 12, a fine motion table stator frame 10 and an electromagnetic drive module. The bearing table 1 is fixed on the top of the fine motion table mover skeleton 12, and the electromagnetic force drive module of the fine motion table includes four sets of the first three degrees of freedom movement in the horizontal plane along the X direction, the Y direction and around the Z axis. An electromagnetic force drive module 8 and four sets of second electromagnetic force dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com