Side by side composite fiber spinneret plate, method of preparing three-dimensional crimp antibacterial fiber with spinneret plate and application of three-dimensional crimp antibacterial fiber

A composite fiber, three-dimensional crimping technology, applied in the direction of fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc., can solve the loss of crimping characteristics and elasticity, loss of antibacterial effect, and the inability of three-dimensional crimped fibers to remain permanent The three-dimensional curling effect of deformation and other problems can achieve good elasticity and good ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material specifications: Component A is low melting point PET chips, its intrinsic viscosity: 0.450-0.550dL / g, component B is commercially available conventional PET, intrinsic viscosity: 0.580-0.680dL / g; Component C: cuprous oxide , particle size 40 ~ 100 nanometers.

[0028] The composite mass percentage ratio of component A, component B and component C of the side-by-side three-dimensional crimped antibacterial fiber is 60:39:1, and the fineness of a single fiber is between 1.11dtex and 12.00dtex.

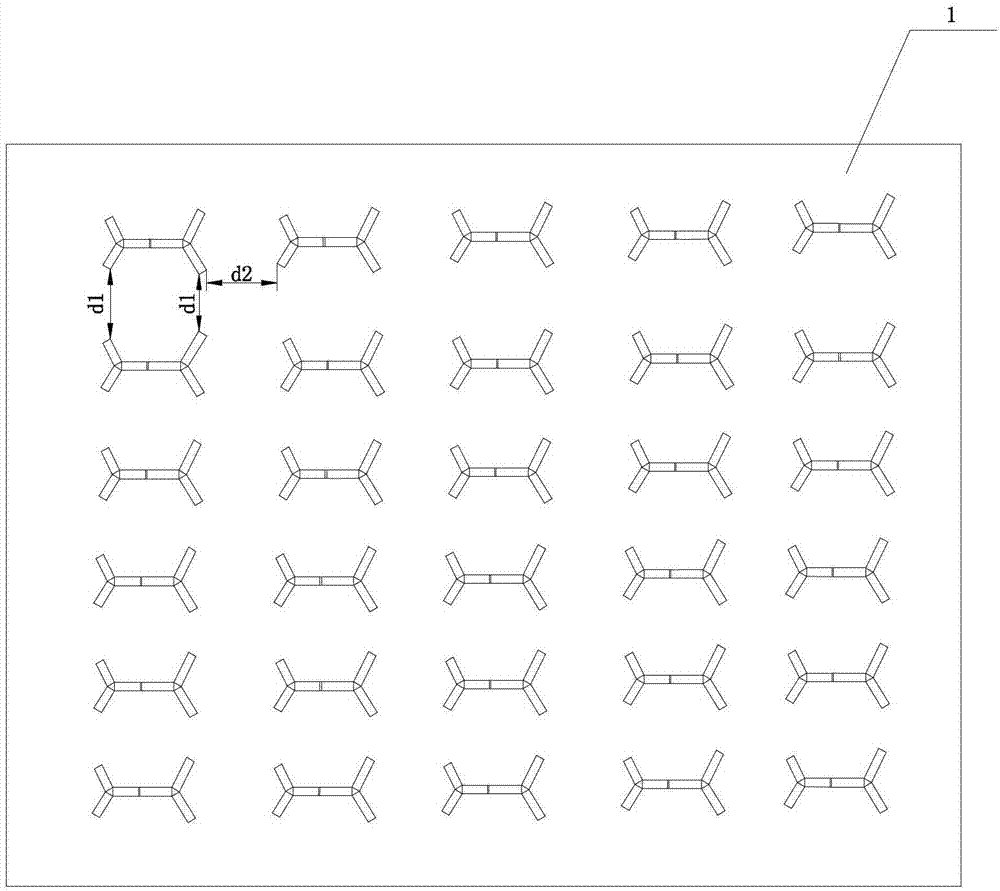

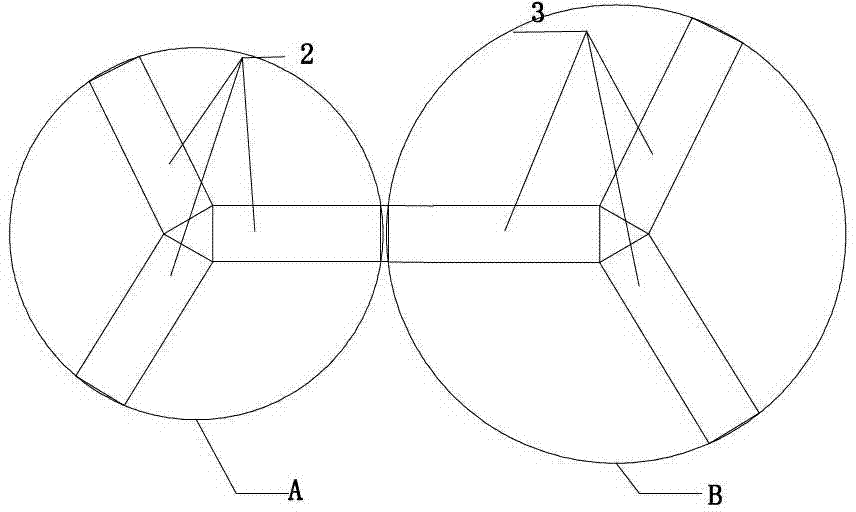

[0029] The side-by-side three-dimensional crimped antibacterial fiber is prepared by using the following side-by-side composite spinnerets: as attached figure 1 with 2 As shown: the plate surface 1 of the spinneret is rectangular or circular, with 72 spinneret holes distributed on it, and the shape of each spinneret hole is as shown in the attached figure 2 Shown: Each spinneret hole consists of two equilateral "trilobal" A and equilateral "trilobal" B (as attached...

Embodiment 2

[0047] Specifications of raw materials: Component A is low melting point PET chip, its intrinsic viscosity: 0.450-0.550dL / g; component B is conventional PBT, intrinsic viscosity: 0.750-0.850dL / g; component C: cuprous oxide, granular 40-100 nanometers in diameter.

[0048] The composite mass percentage of component A, component B and component C of the side-by-side three-dimensional crimped antibacterial fiber is 65:33:2, and the fineness of a single fiber is between 1.11dtex and 18.00dtex.

[0049] Side-by-side spinnerets: the structure is as described in embodiment 1, wherein the length of the small rectangular spinneret hole 2 in the equilateral "trilobe" A is 1.2 millimeters, the width is 0.8 millimeters, and the hole depth is 0.8 millimeters; equilateral " The length of each small rectangular spinneret hole 3 in the trefoil type "B is 0.7 millimeters, the width is 0.4 millimeters, and the hole depth is 0.50 millimeters. Others are the same as embodiment 1. Production proc...

Embodiment 3

[0065] Raw material specifications: Component A is low melting point PET chips, its intrinsic viscosity: 0.450-0.550dL / g; component B is conventional PTT, intrinsic viscosity: 0.800-0.900dL / g; component C: cuprous oxide, granular 40-100 nanometers in diameter.

[0066] The composite mass percentage of component A, component B and component C of the side-by-side three-dimensional crimped antibacterial fiber is 65:33:2, and the fineness of a single fiber is between 1.11dtex and 8.50dtex.

[0067] Side-by-side spinnerets: the structure is as described in Example 1, wherein the length of the small rectangular spinneret holes 2 in the equilateral "trilobe" A is 1.5 millimeters, the width is 0.6 millimeters, and the hole depth is 0.8 millimeters; equilateral " The length of each small rectangular spinneret hole 3 in the three-lobe type "B is 0.9 millimeters, and the width is 0.4 millimeters, and the hole depth is 0.6 millimeters, and others are the same as embodiment 1.

[0068] Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com