Preparation method of rare earth complex/polymer naocomposite plastic film

A rare earth complex and nanocomposite technology, applied in chemical instruments and methods, luminescent materials, organic chemistry, etc., can solve unseen problems, achieve good compatibility, facilitate the transmission of sunlight, and have good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

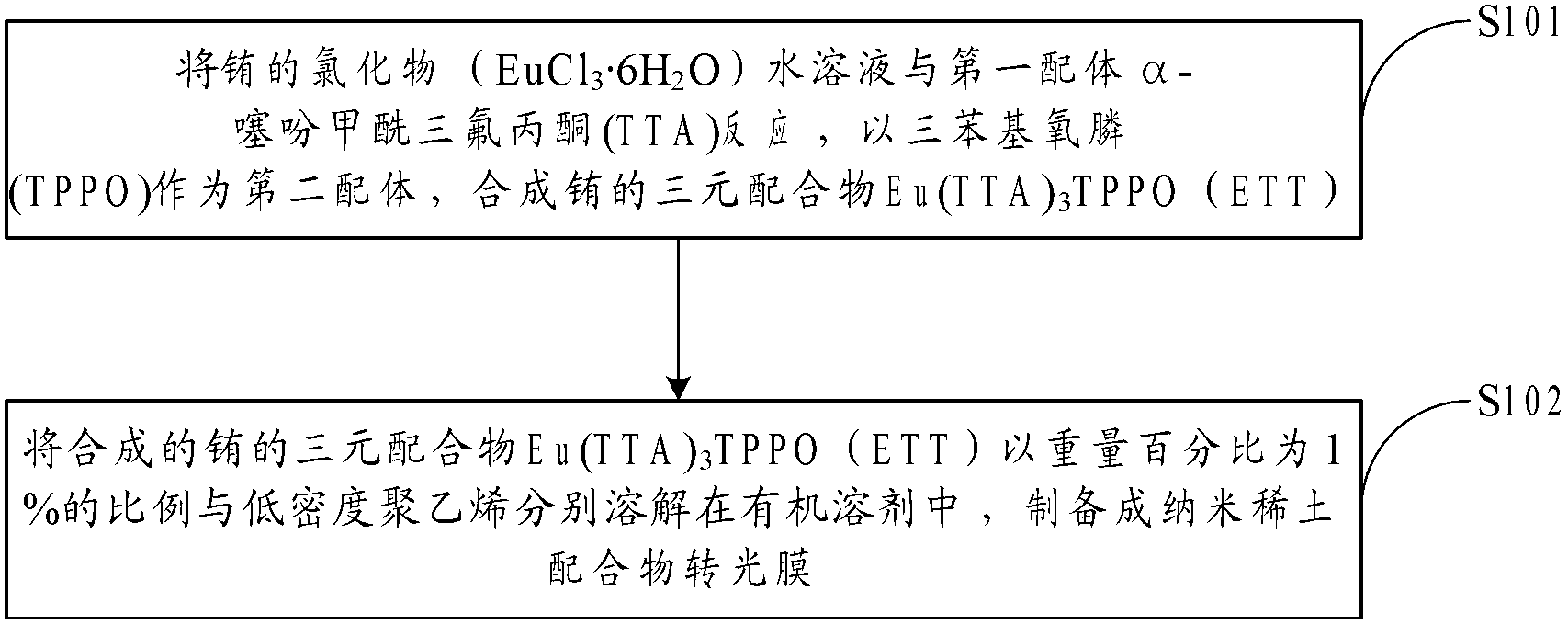

[0036] The preparation method comprises the following steps:

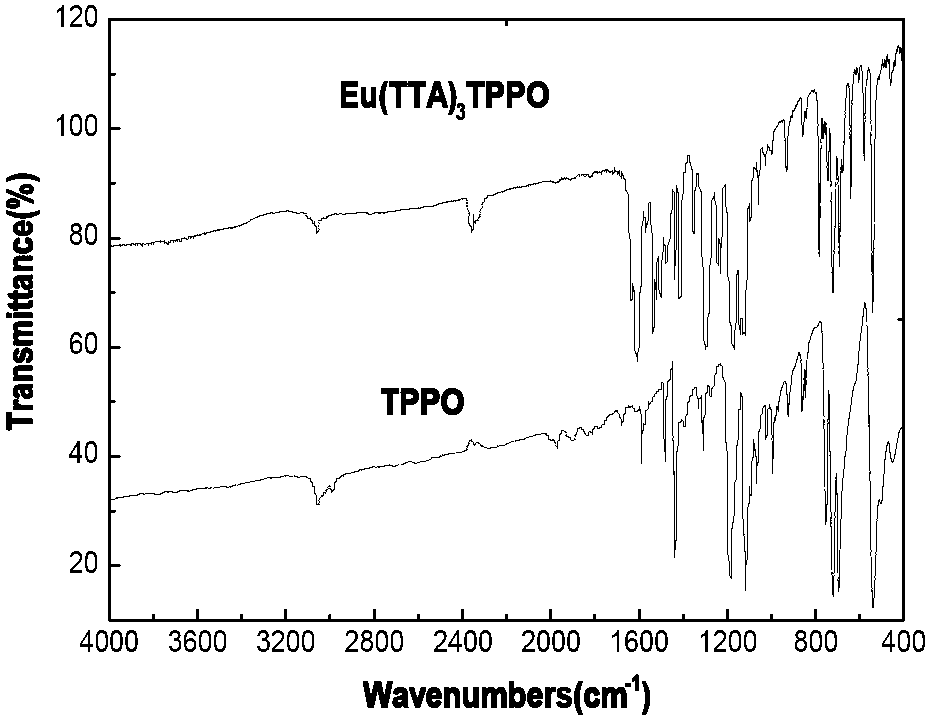

[0037] Step S101, concentration is 0.1mol / L europium chloride (EuCl 3 ·6H 2 O) The aqueous solution reacts with the first ligand α-thienoyltrifluoroacetone (TTA), and triphenylphosphine oxide (TPPO) is used as the second ligand to synthesize the ternary complex Eu(TTA) of europium 3 TPPO (ETT);

[0038] Step S102, the synthetic ternary complex Eu(TTA) of europium 3 TPPO (ETT) was dissolved in an organic solvent with a proportion of 0.3wt% by weight and low-density polyethylene to prepare a nanometer rare earth complex light conversion film.

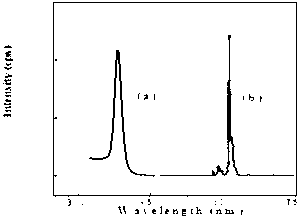

[0039] In the embodiment of the present invention, the preparation method further includes the following steps: using the high polymer extrusion molding process, adding the nano-europium rare earth complex to the low-density polyethylene masterbatch to obtain a uniform and transparent polymer film, Its red fluorescence can be clearly seen at ultraviolet light (365nm).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com