Method for purifying polysaccharide iron complex based on ultrafiltration membrane method

A polysaccharide iron complex technology, applied in the field of purification of polysaccharide iron complexes, can solve problems such as complicated process, affecting product purity, membrane pollution, etc., and achieves the effects of simple operation process, easy continuous production, and reduced salt concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

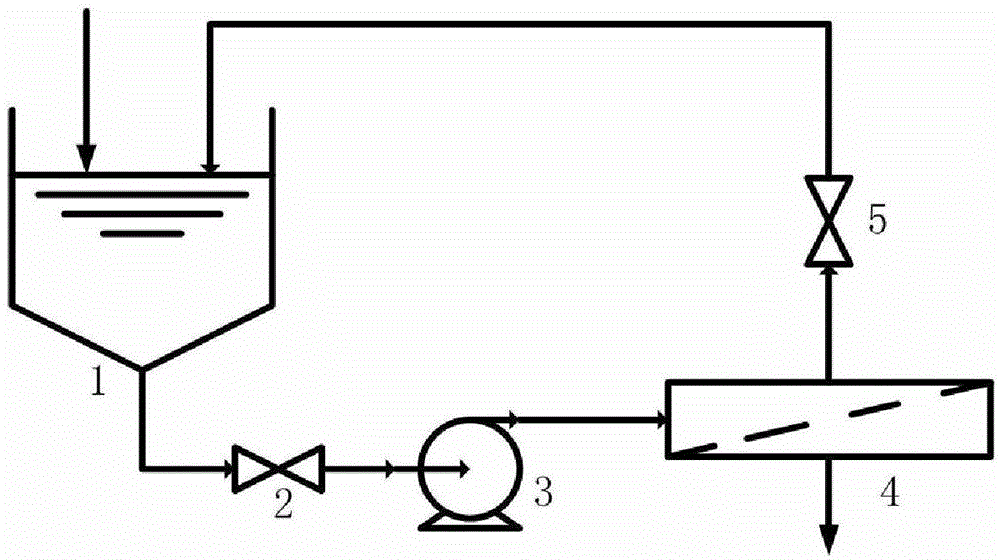

[0020] use figure 1 The shown device processes a crude aqueous solution of pumpkin polysaccharide iron complex synthesized by the ferric chloride method. The ultrafiltration membrane module installed on the device is a multi-channel tubular ceramic ultrafiltration membrane module, the membrane support material is alumina, and the membrane material is Zirconia, the average pore size is 5 nm, and the operation method is cross-flow filtration. First, the crude pumpkin polysaccharide iron complex aqueous solution (with sodium chloride content of about 15.0%wt and iron content of about 50mg / L) in the feed liquid tank 1 is concentrated at a temperature of 60℃ and a pressure of 0.15MPa. When the volume of the retentate in the liquid tank 1 is concentrated to 35% of the original volume, continue to add deionized water to the liquid tank, and control the water addition rate to be equal to the permeation flux of the ultrafiltration membrane until the sodium chloride in the permeate of th...

Embodiment 2

[0022] use figure 1 The shown device processes the crude aqueous solution of angelica polysaccharide iron complex synthesized by ferric chloride method. The ultrafiltration membrane module installed on the device is a rolled polyethersulfone ultrafiltration membrane module with a membrane molecular weight cut-off of 5KDa, and the operation mode is cross-flow filtration . First, the crude angelica polysaccharide iron complex aqueous solution (the sodium chloride content is about 15.0%wt, the iron content is about 50mg / L) in the liquid tank 1 is dialyzed at a temperature of 30°C and a pressure of 0.3MPa, and continues to Add deionized water to the feed liquid tank, and control the water addition rate to be equal to the permeation flux of the ultrafiltration membrane until the sodium chloride concentration in the permeate of the ultrafiltration membrane drops to 2.0%wt, then stop adding water, and intercept the feed liquid tank 1. The liquid volume is concentrated to 20% of the o...

Embodiment 3

[0024] use figure 1 The shown device processes the crude aqueous solution of Lycium barbarum polysaccharide iron complex synthesized by the ferric chloride method. The ultrafiltration membrane module installed on the device is a flat polyamide ultrafiltration membrane module, the membrane molecular weight cut-off is 10KDa, and the operation mode is dead-end filtration. First, the crude wolfberry polysaccharide iron complex aqueous solution (with sodium chloride content of about 15.0%wt and iron content of about 50mg / L) in the liquid tank 1 is concentrated at a temperature of 25°C and a pressure of 0.2MPa. When the volume of the retentate in the liquid tank 1 is concentrated to 50% of the original volume, continue to add deionized water to the feed liquid tank, and control the water addition rate to be equal to the permeation flux of the ultrafiltration membrane until the sodium chloride in the permeate of the ultrafiltration membrane The concentration drops to 1.9%wt. At this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com