Sand blasting rust removal apparatus

A technology of sandblasting and derusting and sandblasting, which is applied in the direction of used abrasive processing devices, abrasive jetting machine tools, abrasives, etc., and can solve the problems of heavy sandblasting and derusting work, polluting the environment, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The wet sand delivery device includes a conveyor belt 17 .

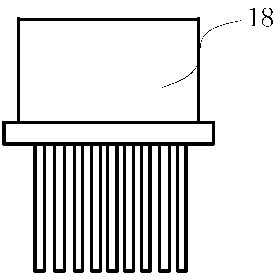

[0019] like figure 2 As shown, the conveyor belt 17 is provided with a sand spreading grate 18, which spreads the wet sand to facilitate subsequent drying.

[0020] The wet sand drying device includes a drying hopper 19, the upper opening of the drying hopper 19 is used as the wet sand inlet 2, and one side of the upper opening is located below the discharge end of the conveyor belt 17, and is connected to the conveyor belt 17. A fan 20 is provided on the other side of the opening of the upper end opposite to the discharge end of the belt 17 . The below of the delivery end of the conveyor belt is provided with a sand baffle 28, and the wet sand falling from the delivery end of the conveyor belt 17 is blown and dehumidified under the action of the blower fan, and the sand baffle prevents the sand particles from being blown out of the drying bucket by the wind.

[0021] The bottom of the drying hopper 19 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com