Titanium dioxide microsphere array supported platinum visible-light photocatalyst and preparation method

A titanium dioxide, microsphere array technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low photocatalytic quantum efficiency, limited solar energy utilization, solar energy It can not achieve the problems such as good degradation effect, easy control of preparation parameters, and uniform composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

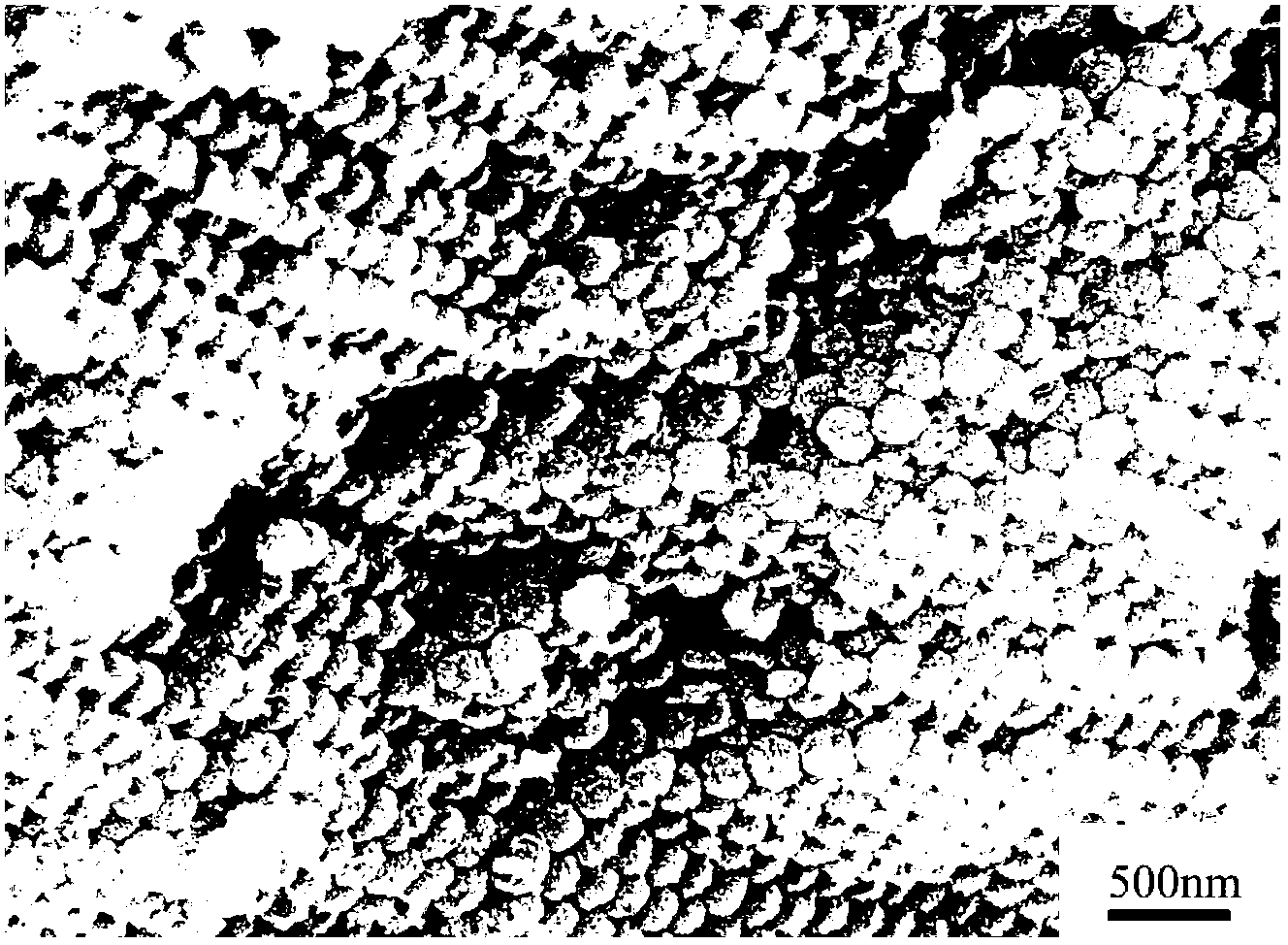

Image

Examples

Embodiment 1

[0023] (1) Mix 4ml, 7ml, and 40ml of deionized water, 13mol / L ammonia water and absolute ethanol, then add 2g of tetraethyl orthosilicate and 50ml of ethanol mixture, at 20°C Stir for 18 hours. After the reaction, wash with ethanol and deionized water several times, settle and self-assemble, calcinate at 750°C, and soak it in a solution with a mass ratio of benzoyl peroxide to methyl methacrylate of 1:100 , polymerized at 60°C. The excess polymer was removed with tetrahydrofuran, and the silica template was removed with 2% HF solution by mass fraction to obtain a PMMA (polymethyl methacrylate) counter-template.

[0024] (2) Add 2 g of isopropyl titanate dropwise into 2 g of hydrochloric acid solution, stir for 0.5 h, then add 5 ml of ethanol solution, and continue stirring for 2 h to obtain a titanium sol. The PMMA template was soaked in the titanium sol for 4h, then taken out and aged for 2d, and calcined at 400°C for 4h to remove the polymer.

[0025] (3) Weigh 0.5g of the...

Embodiment 2

[0029] The preparation method of platinum-supported titanium dioxide microsphere array catalyst, the steps are the same as in Example 1, the difference is: the quality of chloroplatinic acid used is 0.01g

[0030] Weigh 0.02g of the platinum-supported titanium dioxide opal catalyst prepared above to carry out the experiment of visible light catalytic degradation of rhodamine B, the concentration of rhodamine B is 5mg L -1 , the degradation rate of Rhodamine B was 87.3% after visible light irradiation for 1h.

Embodiment 3

[0032] The preparation method of the platinum-supported titania opal catalyst, the steps are the same as in Example 1, except that the quality of chloroplatinic acid used is 0.015g

[0033] Weigh 0.02g of the platinum-supported titanium dioxide opal catalyst prepared above to carry out the experiment of visible light catalytic degradation of rhodamine B, the concentration of rhodamine B is 5mg L -1 , the degradation rate of Rhodamine B was 93.6% after visible light irradiation for 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com