Inks and processes to make a chalcogen-ontaining semiconductor

A chalcogen, ink technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, ink and other directions, can solve problems such as high reactivity and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

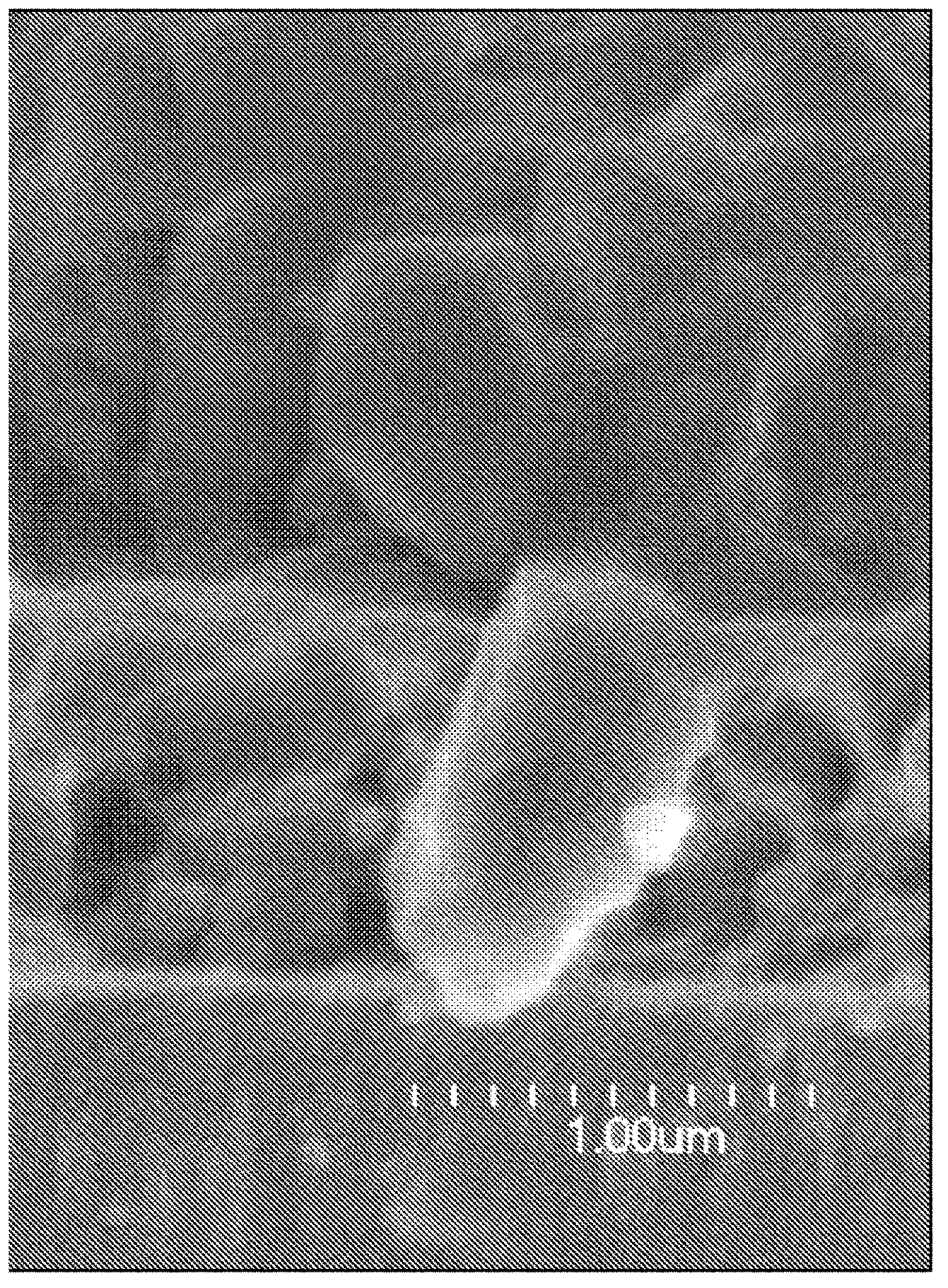

[0141] SnS and ZnS nanoparticles (prepared as described above) were each dispersed in THF at a concentration of 500 mg nanoparticles / mL THF. Each suspension was sonicated for 30 minutes in a bath sonicator, followed by 10 minutes with an ultrasonic probe. The ZnS suspension was passed through a 1.0 micron syringe filter (Whatman, 1.0 micron GF / Bw / GMF). Pass the SnS suspension through a 2.7 micron syringe filter (Whatman, 2.7 micron GF / Dw / GMF). Cu nanoparticles (41.9 mg; purified as described above), 0.1540 mL of ZnS suspension, and 0.3460 mL of SnS suspension were then mixed, and the resulting mixture was sonicated in a bath sonicator for 20 min. The ink was stirred vigorously just before deposition. The ink was spin-coated on the Mo-coated glass substrate by spinning at 1000 rpm for 20 s followed by 1500 rpm for 10 s. then in N 2 , the sample was annealed in a tube furnace at 550°C for 1 hour, and then in sulfur / N 2 annealing at 500°C for 1 hour. The annealed samples we...

example 1

[0142] Example 1A : A coated substrate was prepared according to the method of Example 1. The surface profile was collected at 5 different locations using a Tencor profilometer, and the data was processed with a 25 micron low pass filter, showing an average height of the coated substrate of 1.0715 microns, an average Ra of 460 nm, and an average Wa of 231 nm.

example 2

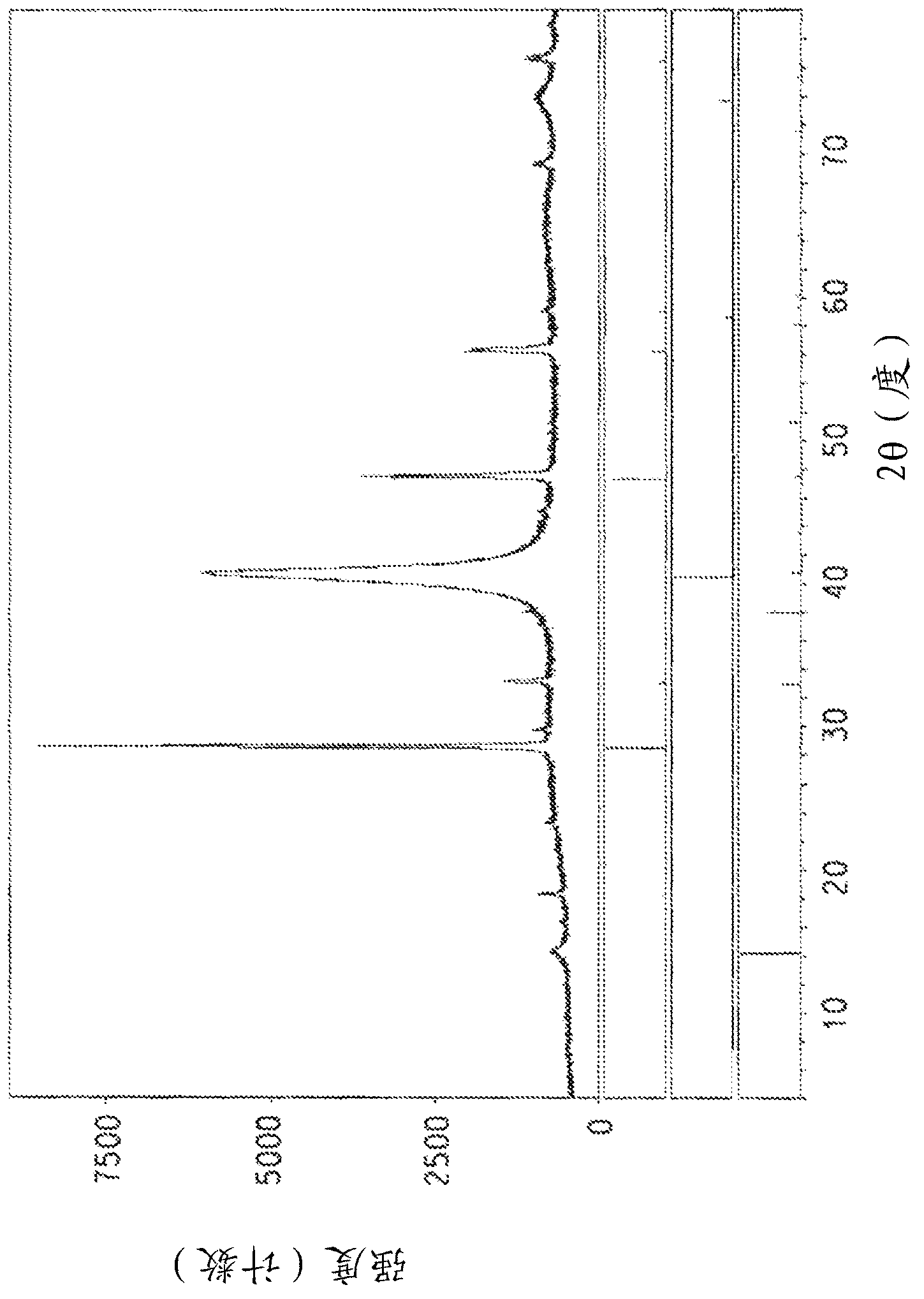

[0144] A CZTS precursor ink was prepared by dispersing commercial Sn nanoscale activated powder (99.7%, 176.5 mg) from Sigma Aldrich and TEGO IL P51P (10.2 mg) in toluene (2258 mg). The dispersion was then sonicated for 15 minutes in an ultrasonic bath. Then CuS particles (298.9 mg) and ZnS particles (274.6 mg) were added to the Sn powder suspension. The mixture was further sonicated for 30 minutes in an ultrasonic bath. The CZTS precursor dispersion was spin-coated onto a molybdenum-coated glass substrate. Ink is applied to the substrate. The sample was then spun at 200 rpm for 10 seconds, followed by 350 rpm for 30 seconds, and finally 600 rpm for 10 seconds. The coated substrates were then allowed to air dry at room temperature. Then in sulfur / N 2 Under atmosphere, the coated substrates were annealed in a tube furnace at 500°C for 2 hours. XRD results indicated that CZTS was the major phase in the annealed films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com