Electrolyte, preparation method and application based on organic sulfur redox couple

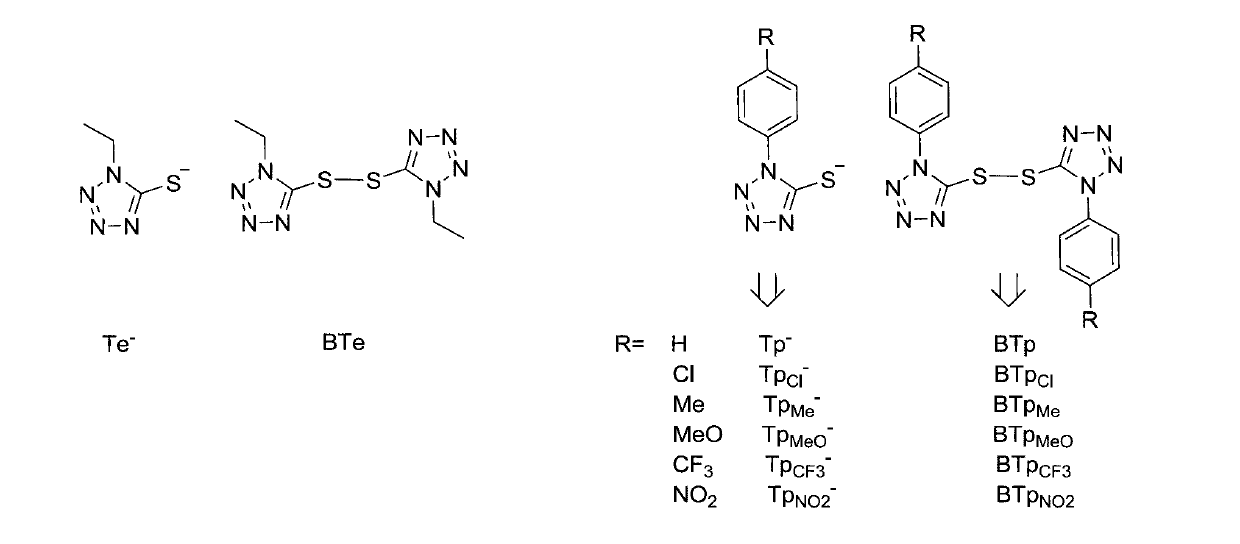

An organic sulfur and electrolyte technology, applied in the field of solar cells, can solve problems such as unfavorable electrolyte ion transport, increase in electrolyte viscosity, decrease in diffusion speed, etc., and achieve the effects of simple process, improved conversion efficiency, and high conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The electrolyte of this embodiment is prepared according to the following method: an organic sulfur salt (such as 2-ethylmercapto tetrazolium lithium salt, the dosage can be 6.8mg, the concentration can be 0.05mmol) and its corresponding disulfide bis(1-ethyl base tetrazolium-5-) disulfide (for example, the amount can be 6.5mg, the concentration is 0.00625mmol), then add crown ether (for example, 12-crown-4), and acetonitrile (preferably 0.25mL) and ethylene carbonate (preferably 0.25mL), ultrasonically dissolves completely to obtain a liquid electrolyte.

[0046] In this embodiment, the organic sulfur salt is not limited thereto, for example, it may also be sodium or potassium salt of 2-ethylmercaptotetrazole.

[0047] The electrolyte was assembled into a liquid dye-sensitized nanocrystalline solar cell. At an intensity of 100mW·cm -2 The simulated solar photovoltaic performance test shows that the closed-circuit photocurrent density J obtained by the solar cell sc ...

Embodiment 2

[0049] The electrolyte of this example is prepared according to the following method: organic sulfur salt (such as 2-phenylmercaptotetrazolium sodium salt, the dosage can be 14.9 mg, the concentration can be 0.075 mmol), crown ether (such as 8.1 μL of 0.05 mmol of 15- crown-5) and the corresponding disulfide bis(1-phenyltetrazole-5-) disulfide (for example, the dosage can be 22mg, the concentration is 0.00625mmol), add a certain amount of acetonitrile (for example, 0.5mL), ultrasonic Dissolve completely to obtain liquid electrolyte.

[0050] The electrolyte was assembled into a liquid dye-sensitized nanocrystalline solar cell. At an intensity of 100mW·cm -2 The simulated solar photovoltaic performance test shows that the closed-circuit photocurrent density J obtained by the solar cell sc =9.26mA / cm 2 , open circuit voltage V oc =632mV, fill factor FF=0.71, photoelectric conversion efficiency η=4.16%.

[0051] In this embodiment, the crown ether can also be 18-crown-6 or o...

Embodiment 3

[0053] The electrolyte of this example is prepared according to the following method: organic sulfur salt (such as 2-p-methoxyphenylmercapto tetrazolium potassium salt, the dosage can be 49.2 mg, the concentration can be 0.2 mmol), crown ether (such as 32.4 μL 0. 2mm ol of 18-crown-6) and the corresponding disulfide bis(1-p-methoxyphenyltetrazolium-5-)disulfide (for example, the dosage can be 42mg and the concentration is 0.1mmol), and add a certain amount Ethylene carbonate (for example, 0.5mL) is completely dissolved by ultrasonication to obtain a liquid electrolyte.

[0054] The electrolyte was assembled into a liquid dye-sensitized nanocrystalline solar cell at an intensity of 100 mW cm -2 The simulated solar photovoltaic performance test shows that the closed-circuit photocurrent density J obtained by the solar cell sc =12.2mA / cm 2 , open circuit voltage V oc =629mV, fill factor FF=0.70, photoelectric conversion efficiency η=5.40%.

[0055] In this embodiment, the org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open circuit voltage | aaaaa | aaaaa |

| Open circuit voltage | aaaaa | aaaaa |

| Open circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com