Support moving mechanical arm for roadway

A robotic arm and rack-moving technology, which is applied to mine roof supports, mining equipment, earth-moving drilling, etc., can solve the problems of repeated support of roadway roofs, slow rack-moving speed, low operation efficiency, etc., and achieves light weight, safe and reliable use. , the effect of moving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

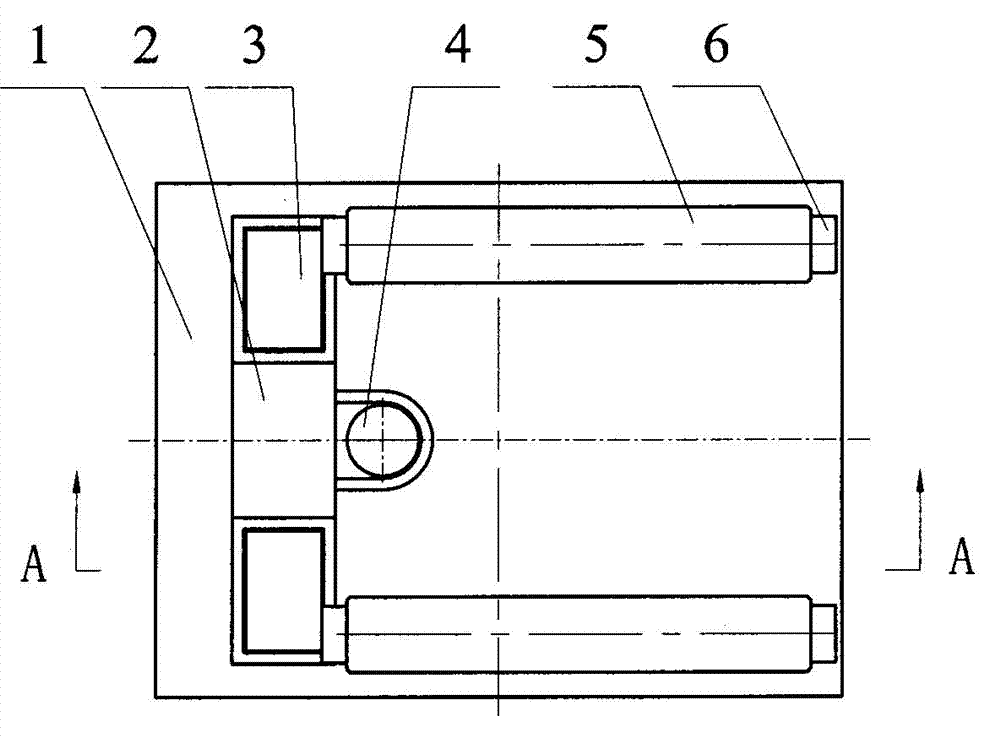

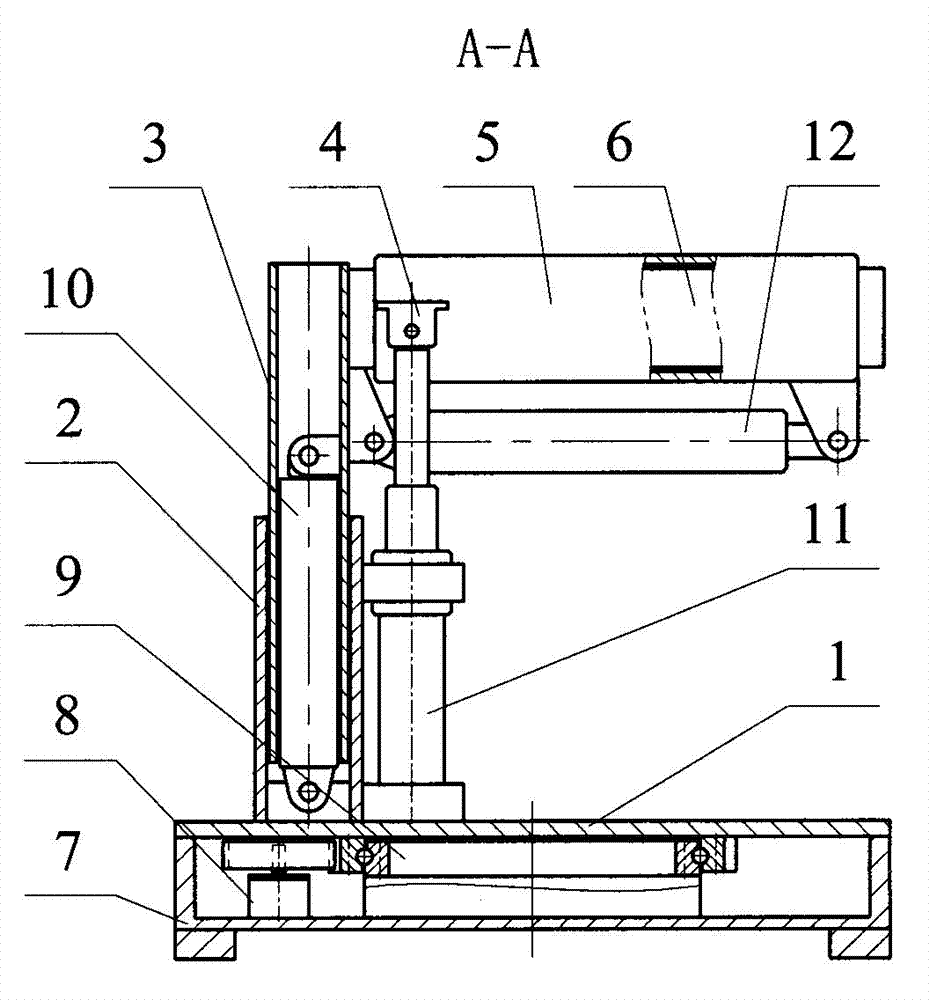

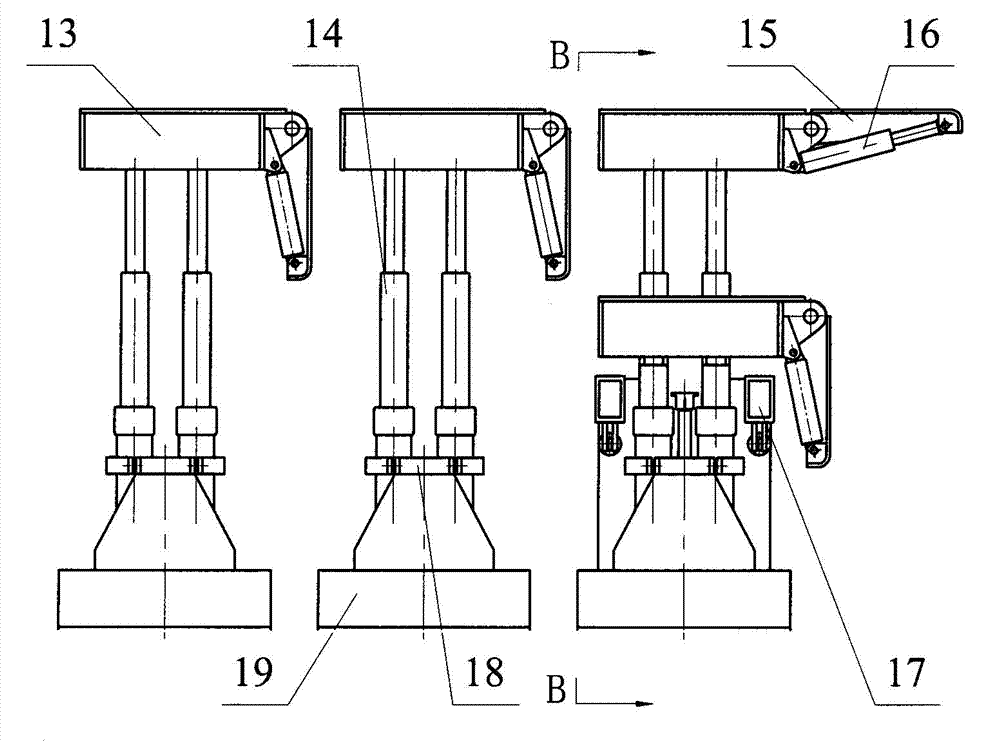

[0016] according to Figure 1~5 The specific structure of the present invention will be described in detail. The roadway frame-moving mechanical arm 17 includes a fixed base 7 at the bottom, a transmission mechanism 9, a rotating base 1 and a lifting mechanism arranged on the rotating base 1, and the like. The lifting mechanism arranged on the rotating seat 1 is composed of a lifting guide sleeve 2, a lifting hydraulic cylinder 10, and a lifting guide rod 3. The upper part of the lifting guide rod 3 is vertically fixed with a cantilever guide rod 6, a cantilever hydraulic cylinder 12 and a cantilever telescopic sleeve 5. The cantilever telescoping mechanism, the top is hinged with the supporting hydraulic column 11 of the supporting base 4 and is fixed on the rotating base 1, and the rotating base 1 is driven to rotate around the center of the rotating shaft by the rotating drive device 8 and the transmission mechanism 9.

[0017] The transmission mechanism 9 is composed of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com