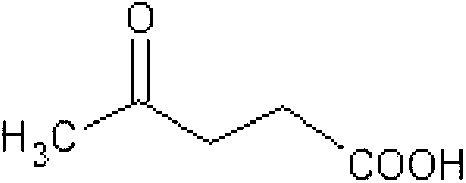

Method for preparing levulinic acid through plant polysaccharide degradation under synergetic catalysis of Lewis acids and Bronsted acid in high-temperature liquid-state water

A technology of Bronsted acid and high temperature liquid water, which is applied in the preparation of organic compounds, the preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of low yield, low levulinic acid, etc. The effect of abundant sources and good prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

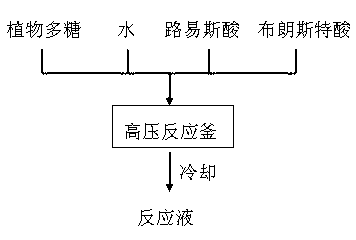

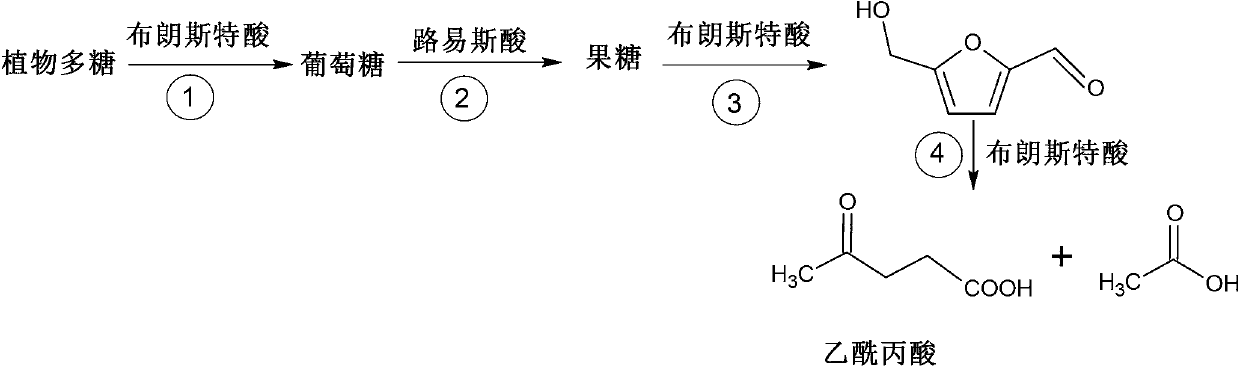

Method used

Image

Examples

Embodiment 1

[0031] Add 300mL of deionized water, 6g of cellulose, and 0.29g of hydrochloric acid in sequence in a 500mL autoclave. The mass concentration of cellulose is 20g / L, and the molar concentration of hydrochloric acid is 0.01mol / L. After sealing, stir and heat up to 145°C Reacted for 8 hours; the reaction product was cooled to obtain a reaction liquid, and the reaction liquid was filtered, analyzed by HPLC, and calculated to obtain a molar yield of levulinic acid of 15.6%.

Embodiment 2

[0033] Add 300mL of deionized water, 15g of starch, and 24.53g of zinc chloride successively in a 500mL autoclave. The mass concentration of starch is 50g / L, and the molar concentration of zinc chloride is 0.60mol / L. React at 150°C for 7 hours; the reaction product was cooled to obtain a reaction solution, which was filtered, analyzed by HPLC, and calculated to obtain a molar yield of levulinic acid of 2.8%.

Embodiment 3

[0035] Add 300mL of deionized water, 15g of cellulose, and 17.29g of phosphoric acid in sequence in a 500mL high-pressure reactor. The mass concentration of cellulose is 50g / L, and the molar concentration of phosphoric acid is 0.50mol / L. After sealing, stir and heat up to 160°C Reacted for 5 hours; the reaction product was cooled to obtain a reaction liquid, and the reaction liquid was filtered, analyzed by HPLC, and calculated to obtain a molar yield of levulinic acid of 7.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com