Isosorbide mononitrate sustained-release pellet, and isosorbide mononitrate quick-release and sustained-release pellet capsule adopting it

A technology of isosorbide dinitrate and sustained-release pellets, which is applied in the field of isosorbide mononitrate membrane-controlled sustained-release pellets and isosorbide mononitrate immediate-release-sustained-release pellet capsules, and can solve problems such as decreased release and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Isosorbide mononitrate membrane-controlled sustained-release pellets with common ball cores and Isosorbide mononitrate immediate-release pellets and capsules using the same

[0034] 1. Prescription (based on 1000 capsules)

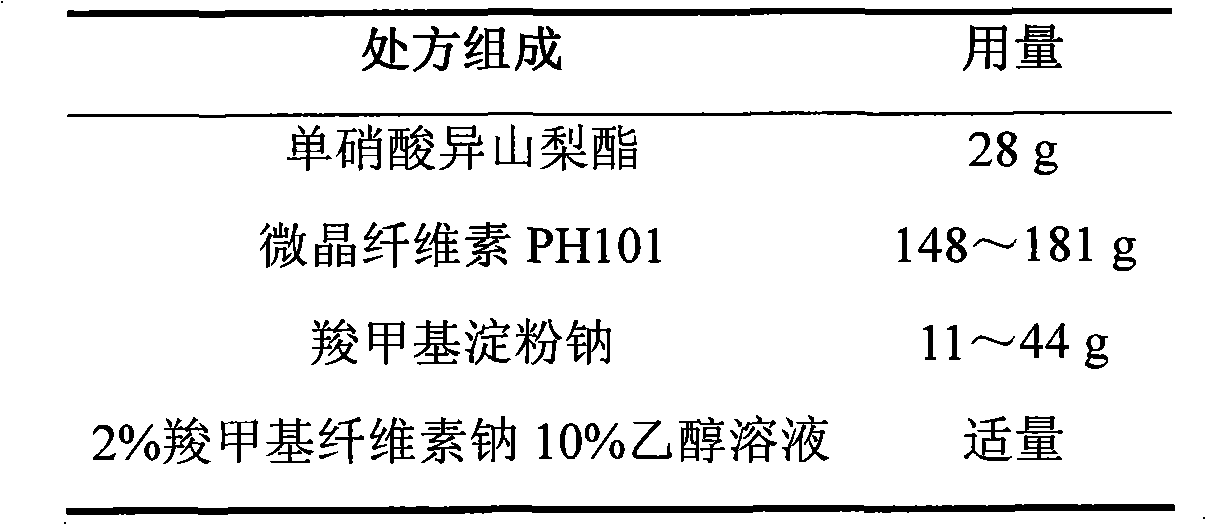

[0035] 1. Prescription for sustained-release pill core:

[0036]

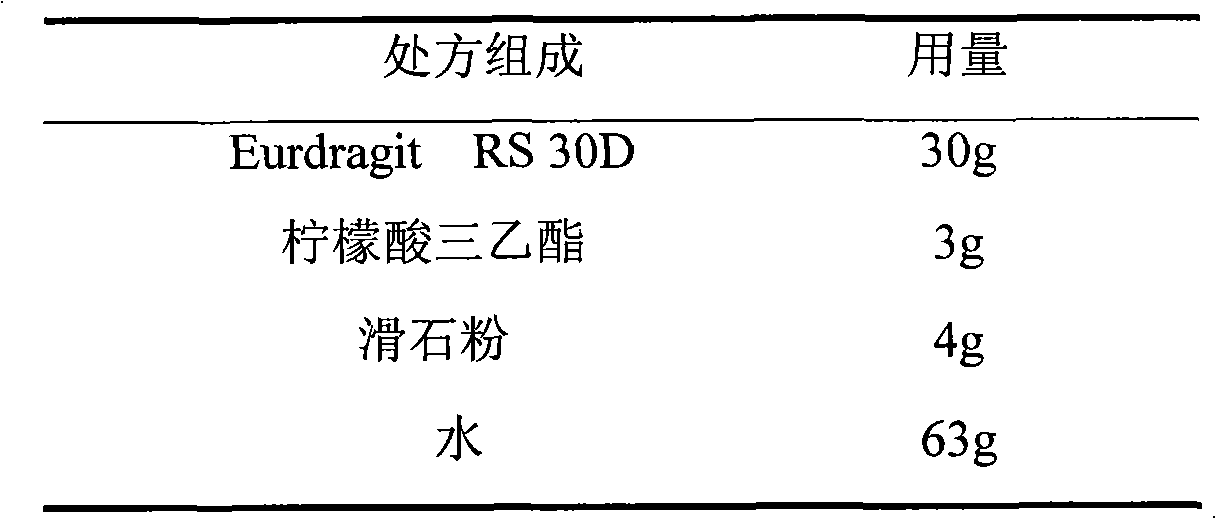

[0037] 2. Prescription of sustained-release film coating solution:

[0038]

[0039] 3. Prescription of immediate-release pellets:

[0040]

[0041]

[0042] 4. No. 0 stomach-soluble gelatin capsule shell 1000 capsules

[0043] Second, the preparation process:

[0044] 1. Preparation process of sustained-release pellet core:

[0045] (1) Isosorbide mononitrate is passed through a 60 mesh sieve;

[0046] (2) Take isosorbide mononitrate and microcrystalline cellulose PH101 of prescription quantity, put in the wet granulator and mix uniformly;

[0047] (3) 2% carboxymethylcellulose sodium 10% ethanol solution to make soft materials;

[0048] (4) Extrude on t...

Embodiment 2

[0075] Example 2 Isosorbide mononitrate film-controlled sustained-release pellets containing 5% sodium carboxymethyl starch and Isosorbide mononitrate immediate-release pellets and capsules using the same

[0076] 1. Prescription (1000 capsules)

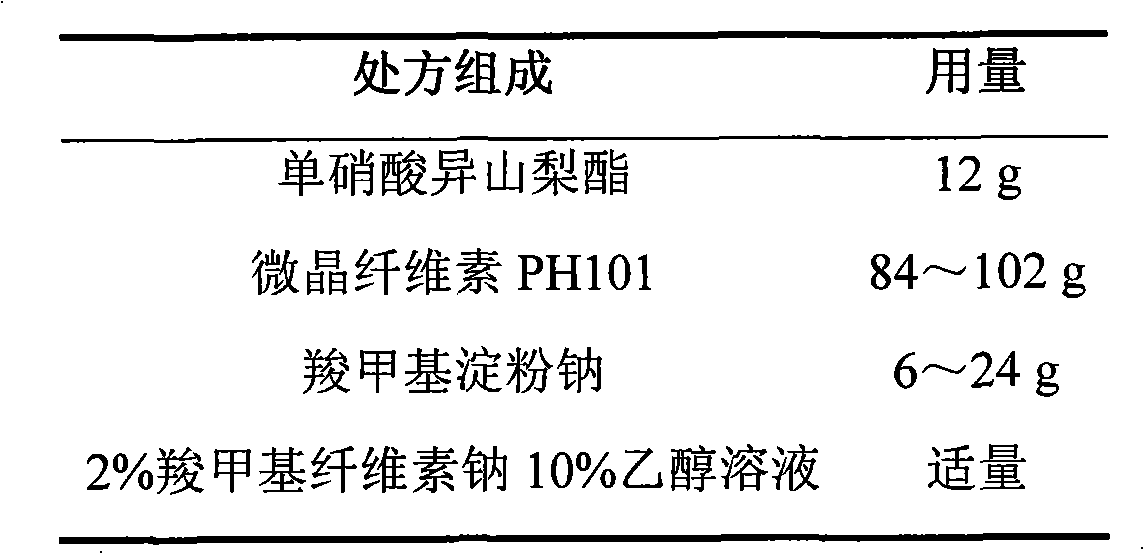

[0077] 1. Prescription of sustained-release pill core

[0078]

[0079] 2. Prescription of sustained-release film coating solution: same as in Example 1

[0080] 3. Prescription of immediate-release pellets

[0081]

[0082] 4. No. 0 stomach-soluble gelatin capsule shell 1000 capsules

[0083] Second, the preparation process:

[0084] 1. Preparation process of sustained-release pellet core:

[0085] (1) Isosorbide mononitrate is passed through a 60 mesh sieve;

[0086] (2) Take isosorbide mononitrate, microcrystalline cellulose PH101, sodium carboxymethyl starch of recipe quantity, put in wet granulator and mix homogeneously;

[0087] (3) 2% carboxymethylcellulose sodium 10% ethanol solution to make soft material;

[008...

Embodiment 3

[0108] Example 3 Isosorbide mononitrate film-controlled sustained-release pellets containing 10% sodium carboxymethyl starch and Isosorbide mononitrate immediate-release-sustained-release pellets capsules using it

[0109] 1. Prescription (1000 capsules)

[0110] 1. Prescription for sustained-release pill core:

[0111]

[0112] 2. Prescription of sustained-release film coating solution: same as in Example 1

[0113] 3. Prescription of immediate-release pellets:

[0114]

[0115] 4. No. 0 stomach-soluble gelatin capsule shell 1000 capsules

[0116] Second, the preparation process:

[0117] 1. Preparation process of sustained-release pellet core: same as in Example 2

[0118] 2. The preparation process of immediate-release pellets: the same as the preparation process of sustained-release pellet cores.

[0119] 3. The preparation process of the slow-release film coating solution: the same as in Example 1

[0120] 4. Coating (sustained release film):

[0121] The slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com