Soybean protein and preparation method thereof

A technology for soybean protein and soybean protein isolate, which is applied in the field of preparation of soybean protein with high foam stability, can solve problems such as reducing foam stability, and achieve the effects of improving foam performance, improving functional properties and improving use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of soybean protein isolate: crush soybean defatted soybean meal and pass through an 80-mesh sieve to obtain defatted soybean powder, mix it with water at a mass ratio of 1:10, stir at medium speed for 2 hours at room temperature, adjust the pH to 8.0 with 2mol / L NaOH, Then centrifuge at 8000rpm for 20min. Take the supernatant and adjust the pH to 4.5 with 2mol / L HCL, let stand at 4°C for 30min, centrifuge at 6000rpm for 15min to obtain the soybean protein precipitate, dissolve the protein precipitate with deionized water according to the solid-liquid mass ratio of 1:7, and use 2mol / L NaOH to adjust the pH to 7.5. Then the mixture was dialyzed in deionized water for 48 h, during which the water was changed 3 times. Finally freeze-dry to obtain soybean protein isolate.

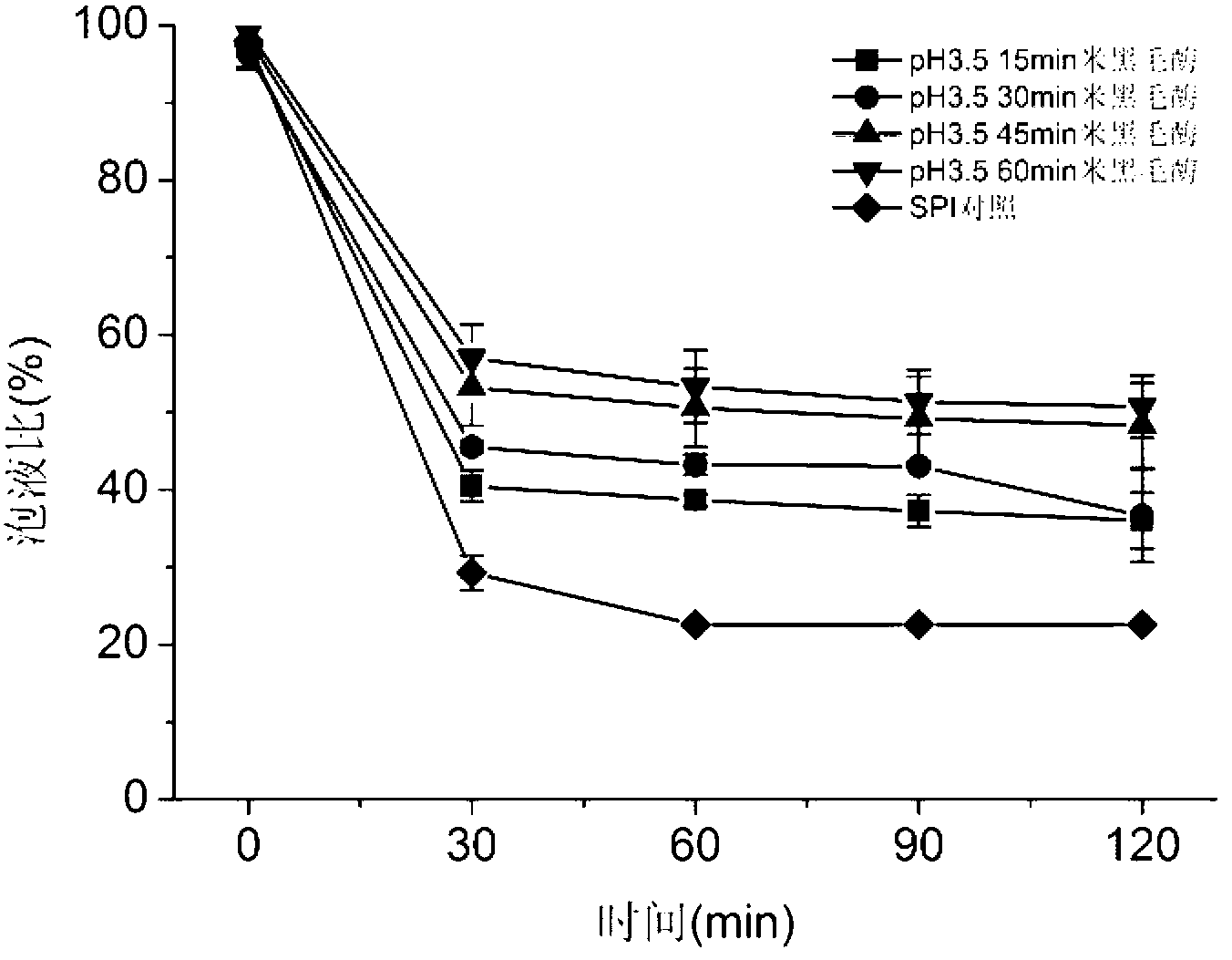

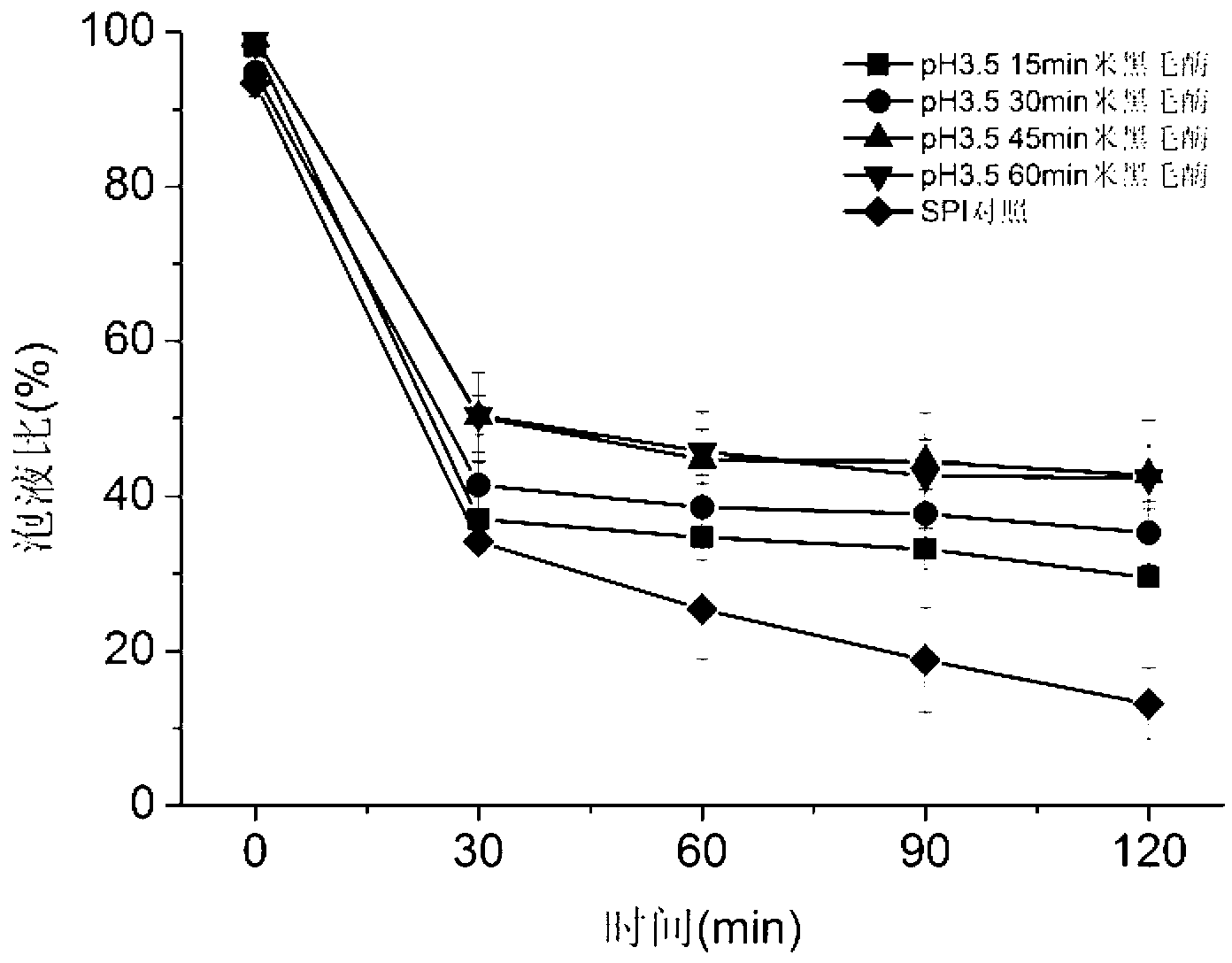

[0029] The foaming ability and foam stability of soybean protein are measured as follows: put 50mL of 1% (W / V) soybean protein solution in a 100mL beaker (diameter 6cm, height 7cm), use a hi...

Embodiment 1

[0032] Accurately weigh 0.5g of soybean protein isolate, add deionized water to stir and dissolve, and make a 1% (w / v) protein solution, bathe in 90°C water for 30 minutes, cool to room temperature, adjust pH to 3.5, add 0.2% (w / w ) of Michelia chinensis enzyme was hydrolyzed in a water bath at 50°C for 15 minutes, and the pH of the reaction was kept at 3.5 by adding 1mol / L HCl (1mol / LNaOH) dropwise during the water bath. Then inactivate the enzyme in a water bath at 85°C for 15 minutes. Finally, the soybean protein hydrolyzate was cooled to room temperature, the pH was adjusted to 5.0, and the soybean protein powder with high foam stability was obtained through freeze-drying.

[0033] It is 41.4% that the foaming power of soybean protein hydrolyzate is measured, compared with soybean protein isolate (41.3%), only improved 0.2%, and the foam stability of this part protein is measured to be 36%, compared with soybean protein isolate ( 13.2%) increased by 172.7%.

Embodiment 2

[0035] Accurately weigh 0.5g of soybean protein isolate, add deionized water to stir and dissolve, and make a 1% (w / v) protein solution, bathe in 90°C water for 30 minutes, cool to room temperature, adjust pH to 3.5, add 0.2% (w / w ) of Miguelase, hydrolyzed in a water bath at 50°C for 30 minutes, and kept the reaction pH at 3.5 by adding 1 mol / L HCl (1 mol / L NaOH) dropwise during the water bath. Then inactivate the enzyme in a water bath at 85°C for 15 minutes. Finally, the soybean protein hydrolyzate was cooled to room temperature, the pH was adjusted to 5.0, and the soybean protein powder with high foam stability was obtained through freeze-drying.

[0036] It is 49.3% that the foaming power of soy protein hydrolyzate is measured, compared with soy protein isolate (41.3%), it has improved by 19.4%, and the foam stability of this part protein is recorded as 36.6%, compared with soy protein isolate (13.2%) %) increased by 177.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| foam stability | aaaaa | aaaaa |

| foam stability | aaaaa | aaaaa |

| foam stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com