Direct current motor control circuit with heat protection function

A DC motor and control circuit technology, applied in emergency protection circuit devices, electrical components, etc., can solve problems such as system failure to remind users to deal with, overheating, spontaneous combustion, etc., achieve low power consumption and voltage drop, simple implementation method, and prevent risk of accidents smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

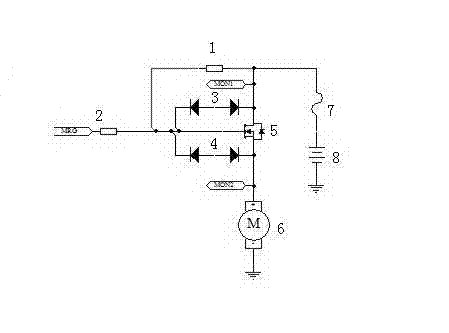

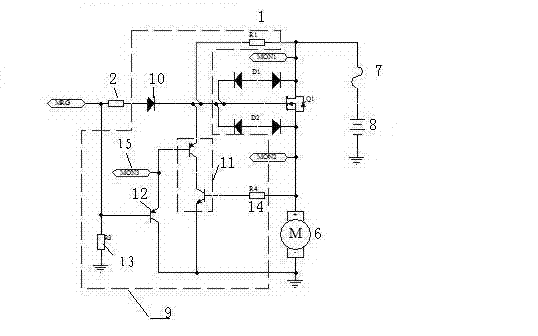

[0013] figure 1 The schematic diagram of the circuit structure of the general DC motor control circuit is shown. In the automotive electronic control unit, especially the drive circuit unit, for safety reasons, it is generally recommended to use a high-end drive structure, and in order to ensure the efficiency of power conversion, a high-end switch tube is required. The driving voltage is higher than the input power supply voltage, so a boost circuit is generally required to realize it, and the output of the boost circuit is generally designed to be twice the input voltage source. Normally, when MRG gets a drive signal, Q1 turns on and the motor runs. If there is an over-current situation, when the time exceeds the specified time, the fuse will blow to protect the control circuit. When MRG loses the drive signal, Q1 is cut off and the motor stops. However, in some specific cases, due to the infiltration of the conductive solution into the electronic control unit, the gate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com