Linear heating wire device

A heating wire and wire-shaped technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of high cost, large change of polymer heat-sensitive layer 3a with time, and inability to control temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

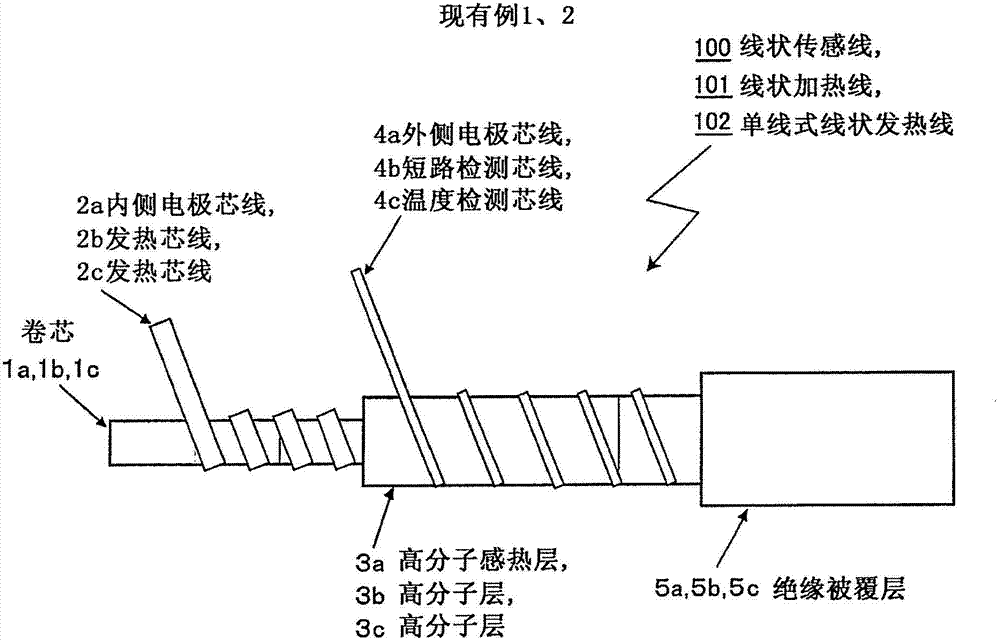

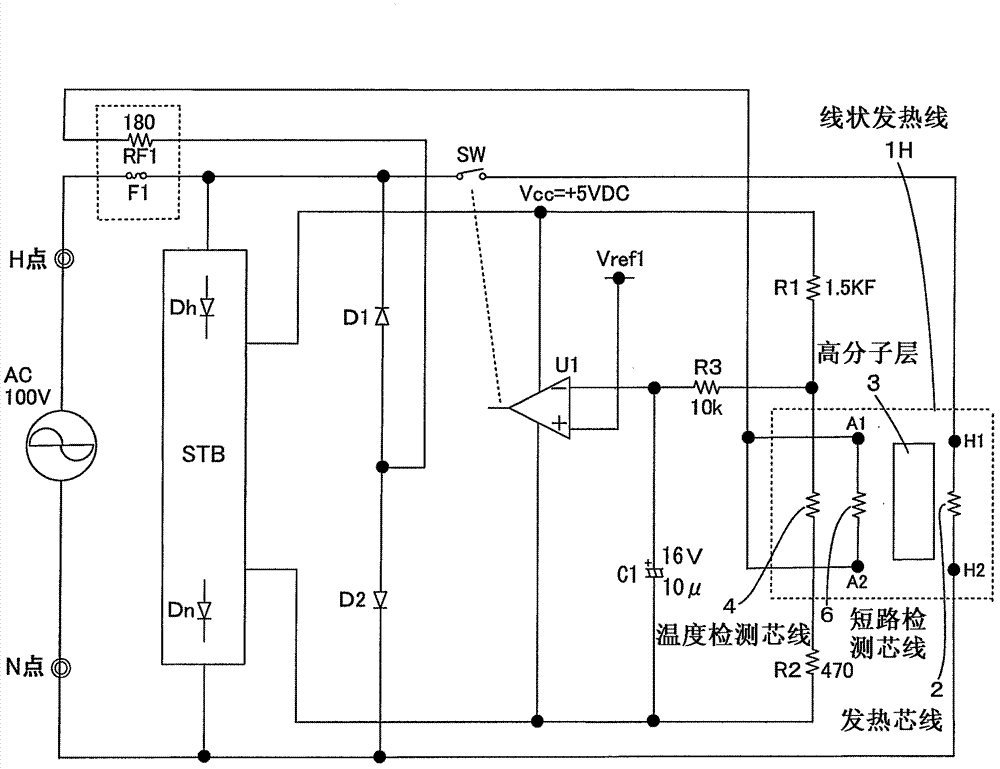

[0092] Embodiments of the linear heating wire of the present invention will be described in detail below with reference to the drawings and the like. In addition, this invention is not limited to the following unless it deviates from the summary. figure 1 One end of the linear heating wire 1H according to the embodiment of the present invention is shown, and an insulating coating layer, a polymer layer, and the like are partially omitted.

[0093] This linear heating wire 1H is composed of a winding core 1 of fiber bundles such as glass fibers or polyester fibers; A polymer layer 3 formed by extruding a polymer thermosensitive resin on the outer periphery of the heating core wire 2; a short circuit of the temperature detecting core wire 4 that is spirally wound at a certain pitch by setting mutual intervals on the outer periphery of the polymer layer 3 The detection core wire 6; and the insulating covering layer 5 formed by extruding polyvinyl chloride or the like on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com