Gradient cathode piece and lithium ion battery preparation method with same

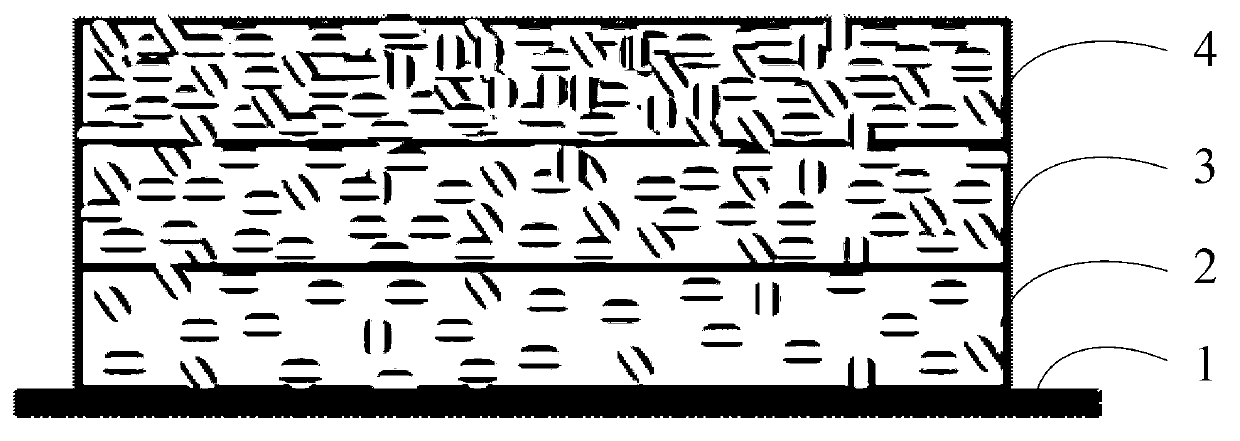

A negative electrode pole piece and gradient technology, which is applied in the field of gradient negative pole piece and the preparation of lithium ion batteries, can solve the problems of volume expansion of alloy negative pole piece, deterioration of battery performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

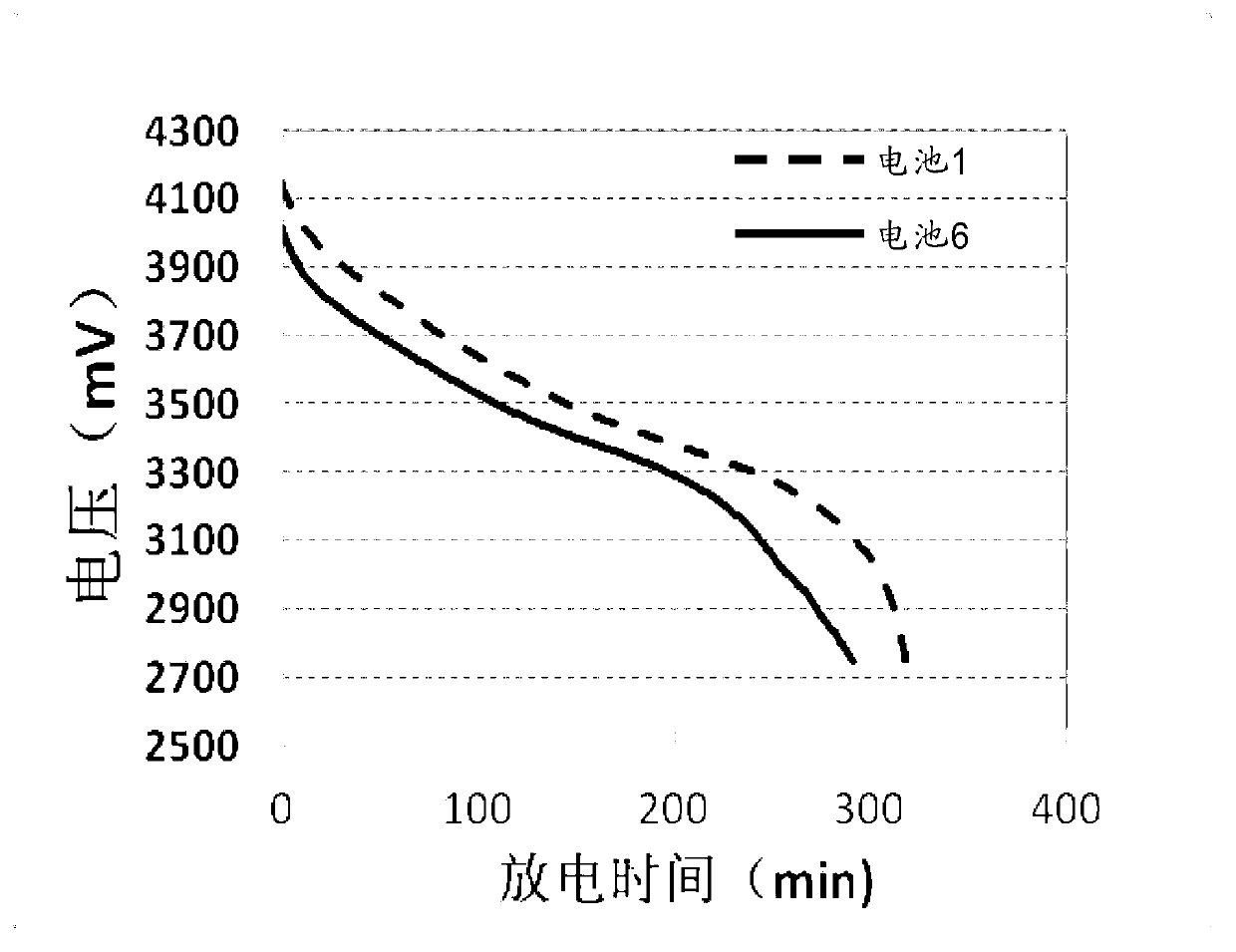

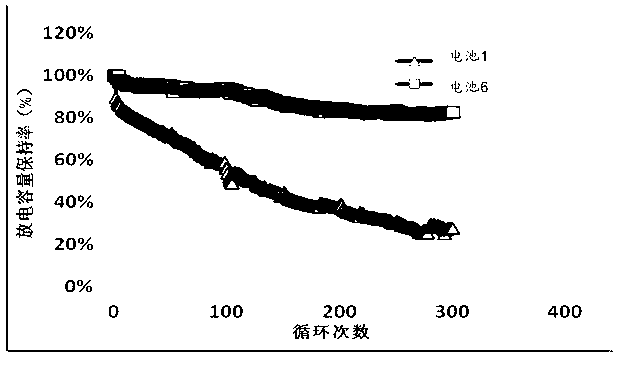

Examples

Embodiment 1

[0041] The first step gradient slurry layer slurry preparation

[0042] 1) After mixing 45 grams of carbon-silicon alloy, 50 grams of mesophase carbon microspheres, 5 grams of super-P, 3 grams of methyl cellulose (CMC), and 2 grams of styrene-butadiene rubber (SBR), add 1000 grams of water and stir well , adjust the viscosity to 400-600Pa·s, pass through a 200-mesh sieve, and make slurry I.

[0043] 2) Mix 65 grams of carbon-silicon alloy, 25 grams of mesophase carbon microspheres, 4 grams of super-P, 3 grams of methyl cellulose (CMC), 3 grams of styrene-butadiene rubber (SBR), and add 1000 grams of water. Viscosity 400~1000Pa·s, pass through 200 mesh sieve, make slurry II.

[0044] 3) Mix 90 grams of carbon-silicon alloy, 3 grams of super-P, 3 grams of methyl cellulose (CMC), 4 grams of styrene-butadiene rubber (SBR), add 1000 grams of water, mix and stir, adjust the viscosity to 800-1500Pa·s, pass 200 mesh sieve to make slurry III.

[0045] The second step of gradient neg...

Embodiment 2

[0056] The first step gradient slurry layer slurry preparation:

[0057] 1) Mix 40 grams of silicon alloy, 40 grams of artificial graphite, 10 grams of super-P, 2 grams of methyl cellulose (CMC), 3 grams of styrene-butadiene rubber (SBR), and add 1000 grams of water to adjust the viscosity to 400-600Pa ·s, pass through a 200-mesh sieve to make slurry I.

[0058] 2) Mix 65 grams of silicon alloy, 20 grams of artificial graphite, 10 grams of super-P, 3 grams of methyl cellulose (CMC), 2 grams of styrene-butadiene rubber (SBR), and add 1000 grams of water to adjust the viscosity to 400-1000Pa s, pass through a 200-mesh sieve to make slurry II.

[0059] 3) Mix 80 grams of silicon alloy, 10 grams of artificial graphite, 5 grams of super-P, 3 grams of methyl cellulose (CMC), 2 grams of styrene-butadiene rubber (SBR), and add 1000 grams of water to adjust the viscosity to 800-1500Pa ·s, pass through a 200-mesh sieve to make slurry III.

[0060] The second step of gradient negative...

Embodiment 3

[0069] The first step gradient slurry layer slurry preparation:

[0070] 1) Mix 42 grams of tin alloy, 45 grams of natural graphite, 7 grams of super-P, 2 grams of methyl cellulose (CMC), 3 grams of styrene-butadiene rubber (SBR), and add 1000 grams of water to adjust the viscosity to 400-600Pa ·s, pass through a 200-mesh sieve to make slurry I.

[0071] 2) Mix 63 grams of tin alloy, 27 grams of natural graphite, 5 grams of super-P, 3 grams of methyl cellulose (CMC), 2 grams of styrene-butadiene rubber (SBR), and add 1000 grams of water to adjust the viscosity to 400-1000Pa s, pass through a 200-mesh sieve to make slurry II.

[0072] 3) Mix 92 grams of tin alloy, 3 grams of super-P, 3 grams of methyl cellulose (CMC), 2 grams of styrene-butadiene rubber (SBR), add 1000 grams of water, mix and stir, adjust the viscosity to 800-1500Pa·s, and pass 200 Mesh sieve to make slurry III.

[0073] The second step of gradient negative electrode sheet preparation

[0074] 1) Coat the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com