Vapor plating method for organic light-emitting display

An organic and evaporation technology, which is applied in vacuum evaporation coating, sputtering coating, electric solid devices, etc., can solve the problems that the substrate cannot be reached, and achieve the effect of improving the service life, increasing the utilization rate, and avoiding the deformation of the board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

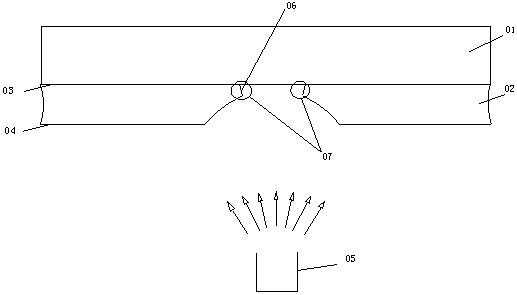

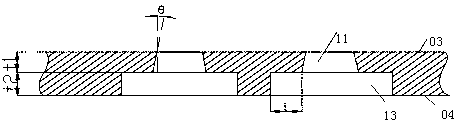

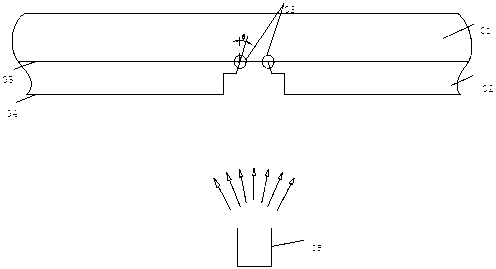

[0035] An organic light-emitting semiconductor evaporation method, comprising the following steps: combining the ITO surface of a mask plate for evaporation with the ITO semiconductor glass surface, and corresponding the evaporation surface of the mask plate to an organic evaporation source; evaporating organic materials, making The organic material is attached to the surface of the ITO semiconductor glass through the opening on the mask plate; the mask plate and the ITO semiconductor glass are separated to complete the evaporation; wherein, the shape of the mask plate is a quadrilateral metal plate, and the mask plate has an ITO surface Layer and evaporation surface layer two-layer structure, the mask plate has an opening through the ITO surface layer and the evaporation surface layer, the opening size of the ITO surface layer is smaller than the opening size of the evaporation surface layer, along the thickness direction of the mask plate In the transverse section, the shape ...

Embodiment 2

[0039] An organic light-emitting semiconductor evaporation method, comprising the following steps: combining the ITO surface of a mask plate for evaporation with the ITO semiconductor glass surface, and corresponding the evaporation surface of the mask plate to an organic evaporation source; evaporating organic materials, making The organic material is attached to the surface of the ITO semiconductor glass through the opening on the mask plate; the mask plate and the ITO semiconductor glass are separated to complete the evaporation; wherein, the mask plate is a rectangular Invar alloy plate metal plate, the The mask plate has a two-layer structure of an ITO surface layer and an evaporation surface layer. The mask plate has an opening through the ITO surface layer and the evaporation surface layer. The opening size of the ITO surface layer is smaller than the opening size of the evaporation surface layer. Along the mask On the transverse section in the thickness direction of the...

Embodiment 3

[0044] An organic light-emitting semiconductor evaporation method, comprising the following steps: combining the ITO surface of a mask plate for evaporation with the ITO semiconductor glass surface, and corresponding the evaporation surface of the mask plate to an organic evaporation source; evaporating organic materials, making The organic material is attached to the surface of the ITO semiconductor glass through the opening on the mask plate; the mask plate and the ITO semiconductor glass are separated to complete the evaporation; wherein, the mask plate is a mask plate for evaporation, and the shape is a rectangular nickel-cobalt alloy The metal plate, the mask plate has a two-layer structure of an ITO surface layer and an evaporation surface layer, and the mask plate has an opening through the ITO surface layer and the evaporation surface layer, and the opening size of the ITO surface layer is smaller than that of the evaporation surface layer. The size of the opening, on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com