Cementing compound for pavement layers

An interlayer and adhesive technology of pavement, applied in the direction of adhesive, adhesive type, asphalt material adhesive, etc., can solve the problems of poor adhesion of asphalt mixture, low asphalt ductility, poor crack resistance, etc. Strong performance, improve mixing construction performance, improve anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: An adhesive for interlayers of pavement, a compound modified by mixing styrene-butadiene-styrene block copolymer SBS, styrene-butadiene rubber powder SBR and neoprene CR at a ratio of 3:1:1. Add 7 kg of agent and 28 kg of terpene resin into the container, then add 50 kg of gasoline, and stir well until a stable emulsion is formed. Then add 14.5 kg of 70°C heated at 80-100°C # Heavy delivery of asphalt and 0.5 kg of decabromodiphenyl ether, fully stirred until completely miscible, sealed in barrels for storage.

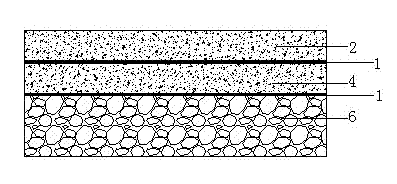

[0021] In general three-layer asphalt pavement (see figure 1 ), the lowermost layer is the pavement base layer 5, before paving the lower layer 4 of asphalt, the base layer 5 needs to be cleaned and sprayed with oil. Between the asphalt lower layer 4 and the asphalt middle layer 3, pave the road interlayer adhesive prepared in this embodiment, and pave the same adhesive between the asphalt middle layer 3 and the asphalt upper layer 2. Before applyi...

Embodiment 2

[0023] Example 2: An adhesive for interlayers of pavement, a compound modified by mixing styrene-butadiene-styrene block copolymer SBS, styrene-butadiene rubber powder SBR and neoprene CR at a ratio of 3:1:1. Add 21 kg of neutralizing agent and 16 kg of terpene resin into the container, then add 45 kg of ethyl acetate, and stir evenly until a stable emulsion is formed. Then add 17 kg of hot 70°C at 80-100°C # Heavy delivery of asphalt and 1 kg of decabromodiphenylethane, fully stirred until completely miscible, sealed in barrels for storage.

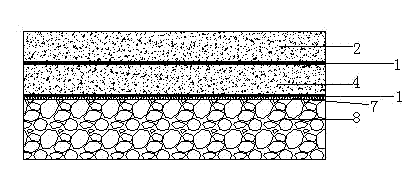

[0024] In the face of cement concrete pavement (see figure 2 ), between the cement concrete layer and the lower asphalt layer 4, and between the upper and lower layers of the asphalt, the pavement interlayer adhesive prepared in this embodiment is used as the adhesive layer. Before the construction of the adhesive layer, the working surface needs to be cleaned, and Keep dry.

[0025] The adhesive is applied to the cement concrete bas...

Embodiment 3

[0026] Example 3: An adhesive for pavement interlayers, which is a composite modification made by mixing styrene-butadiene-styrene block copolymer SBS, styrene-butadiene rubber powder SBR and neoprene CR at a ratio of 3:1:1. Add 14 kg of agent and 22 kg of terpene resin into the container, then add 55 kg of xylene and stir evenly until a stable emulsion is formed. Then add 7 kg of 70# heavy traffic asphalt heated at 80-100 °C and 2 kg of decabromodiphenylethane, stir well until it is completely miscible, and store in a sealed barrel.

[0027] The adhesive is applied to the cement concrete base surface or asphalt concrete base surface by mechanical spraying, and the dosage is controlled at 0.2-0.4kg / m 2 . After the construction is completed, carry out fully enclosed maintenance. The maintenance time is 4 to 8 hours in normal temperature weather, and the maintenance time is extended to 16 to 24 hours when the temperature is lower than 10°C. After the adhesive is completely cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com