Gamma-alumina particles and method for manufacturing same

A technology of alumina particles and pore size, which is applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of high cost, complicated production process, cumbersome production process, etc., and achieve the effect of low cost, simple process and accelerated catalytic reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] Provide a kind of preparation method of gamma-alumina particle in this specific embodiment, comprise the following steps:

[0033] 1) Dissolving the soluble aluminum salt in an aqueous solution acidified by acid with a pH value less than or equal to 3, the amount of the soluble aluminum salt added is such that the molar concentration of aluminum ions in the prepared aluminum-containing aqueous solution is 0.01-5 mol / L.

[0034] Among them, the soluble aluminum salt is aluminum chloride hexahydrate (AlCl 3 ·6H 2 O), anhydrous aluminum chloride (AlCl 3 ), aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O), sodium metaaluminate (NaAlO 2 ), ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 ) and aluminum sulfate octadecahydrate (Al 2 (SO 4 ) 3 18H 2 O) one or more mixtures. The acid is one or a mixture of hydrochloric acid, nitric acid, sulfuric acid, phosphoric acid, formic acid, acetic acid, citric acid and malic acid.

[0035]Preferably, it also includes adding a ...

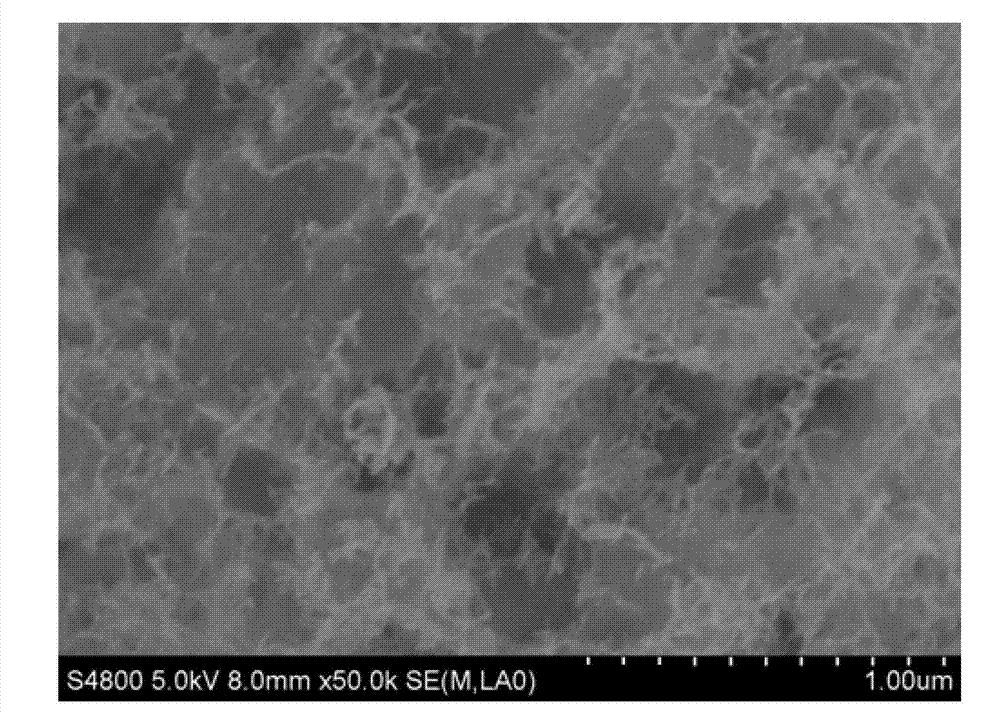

Embodiment 1

[0052] Take 26.16g of AlCl 3(soluble aluminum salt), 0.5g CTAB (pore forming agent) dissolved in 240ml of aqueous solution acidified by hydrochloric acid with a pH value of 3 and mixed evenly, and then an appropriate amount of ammonia water (alkaline precipitant) was added dropwise to the mixed solution to make the transition metal ions Precipitate to form a hydrosol, the amount of ammonia water added dropwise makes the final pH of the solution after the reaction = 8.3, the suspension of the mixed precipitate obtained after the reaction is stirred at room temperature for 2 hours, and the suspension of the mixed precipitate is aged at 90 ° C. After 20 hours, stir the aged water sol evenly and use the spray drying method to atomize and dry. When spray drying, the inlet air temperature is 200°C, the outlet air temperature is 100°C, and the thermal efficiency of spray drying is 50%. After drying, the obtained The alumina precursor powder was heated from room temperature to 350°C a...

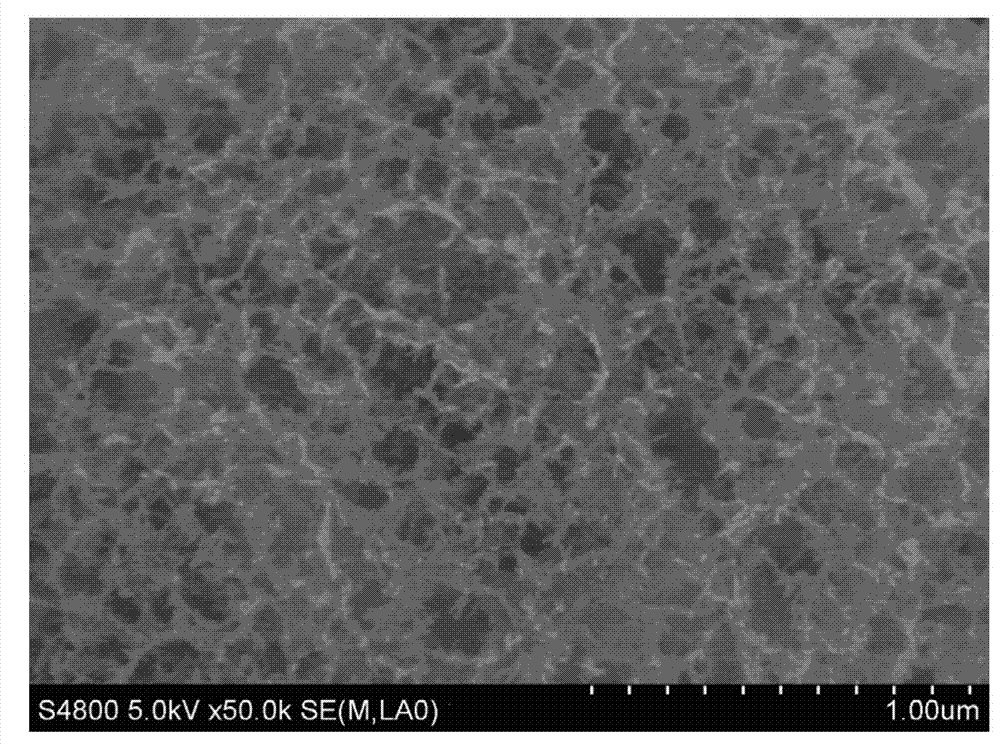

Embodiment 2

[0054] The difference between this example and Example 1 is that in this example, 0.5 g of the pore-forming agent CTAB in Example 1 is replaced by 1 g of the pore-forming agent CTAB. All the other step processes are the same as in Example 1, and the final product γ-Al obtained 2 o 3 Granules, named A-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com