Preparation method of iron trioxide/carbon yolk-eggshell nano-composite structure

A ferric oxide and nano-composite technology, which is applied in the field of composite materials, can solve the problems of matrix material pulverization, low electrical conductivity, and drastic volume changes of ferric oxide, and achieve the effect of alleviating volume expansion and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

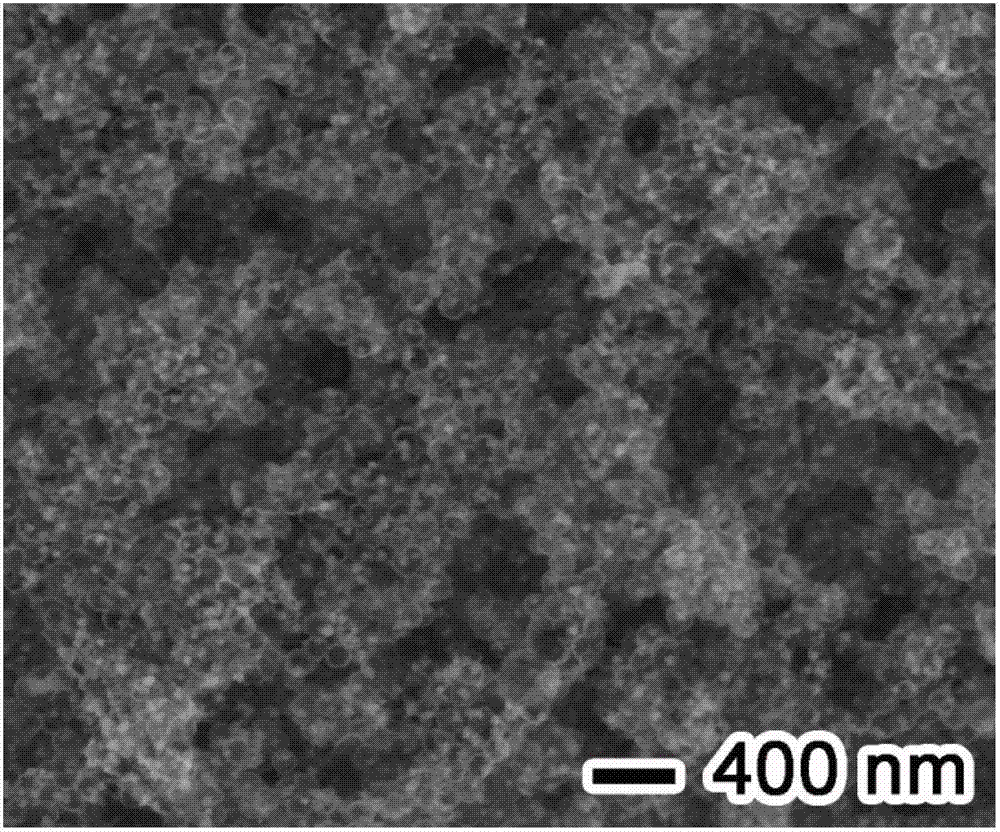

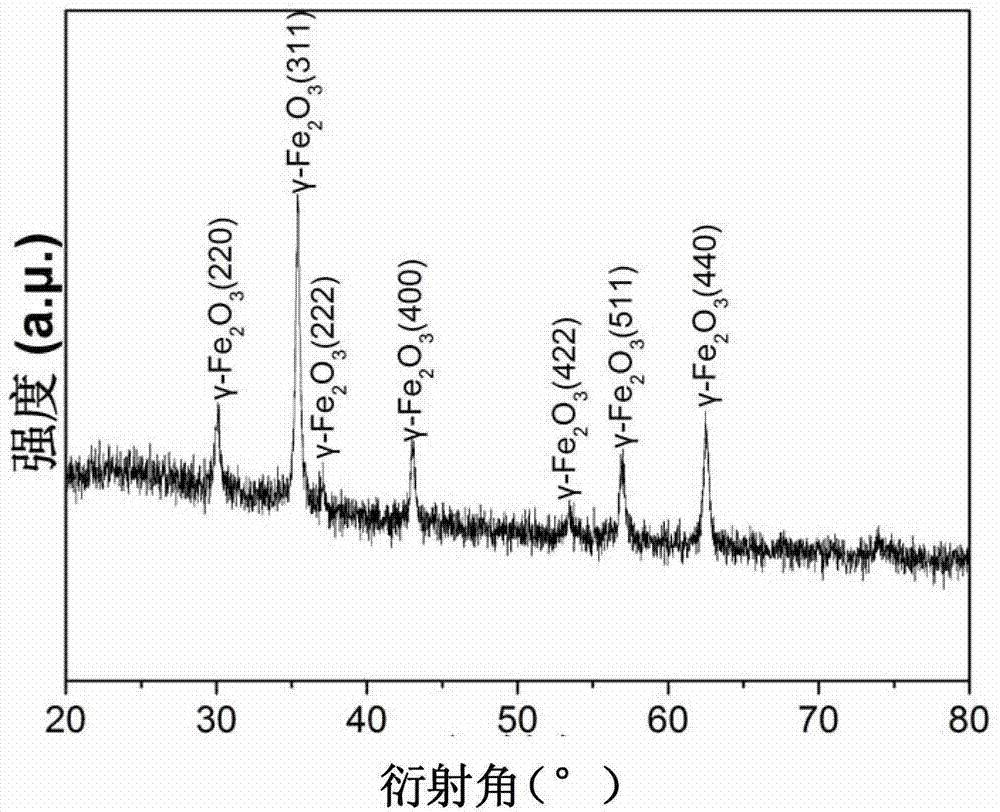

[0026] (1) Preparation of ferric oxide nanoparticles: 0.404g of ferric nitrate nonahydrate and 0.6g of polypropylene pyrrolidone (PVP) were dissolved in 52ml of N,N dimethylformamide (DMF). After uniform ultrasonic dispersion (30 minutes), the solution was transferred to a 100ml autoclave, and reacted at 180°C for 30 hours. After the reaction is finished, centrifuge to obtain nanoparticles of solid product ferric oxide.

[0027] (2) Disperse the nanoparticles of ferric oxide in alcohol, then add a certain proportion (5:1) of water and ammonia water, stir evenly, add tetraethyl orthosilicate and the mass ratio of ferric oxide nanoparticles is 2:1, adjust the pH value to 9, the reaction temperature is 20°C, and react for 24 hours;

[0028] (3) The solution in step (2) is centrifuged and dried, the powder of ferric oxide coated with silicon dioxide and polyvinylidene fluoride are mixed in a ratio of 2:1, dissolved in N-methylpyrrolidone, and stirred for 24 hours After vacuum dr...

Embodiment 2

[0033] (1) Preparation of Fe2O3 nanoparticles, the preparation method is the same as Example 1.

[0034] (2) Disperse the nanoparticles of ferric oxide in alcohol, then add a certain proportion (4:1) of water and ammonia water, stir evenly, add tetraethyl orthosilicate and the mass ratio of ferric oxide nanoparticles is 1:1, the pH value was adjusted to 11, the reaction temperature was 30°C, and the reaction was carried out for 10 hours.

[0035] (3) The solution in step (2) was centrifuged and dried, and the powder of ferric oxide coated with silicon dioxide and polyvinylidene fluoride was mixed in a ratio of 6:1, dissolved in N-methylpyrrolidone, and stirred for 10 hours Then vacuum dry.

[0036] (4) Heat-treat the powder obtained in step (3) in an argon atmosphere at 450° C. for 180 minutes to obtain a composite structure of iron sesquioxide wrapped in silicon dioxide wrapped in carbon.

[0037] (5) Dissolving the powder of the composite structure obtained in step (4) in ...

Embodiment 3

[0039](1) Preparation of Fe2O3 nanoparticles, the preparation method is the same as Example 1.

[0040] (2) Disperse the nanoparticles of ferric oxide in alcohol, then add a certain proportion (5:1) of water and ammonia water, stir evenly, add tetraethyl orthosilicate and the mass ratio of ferric oxide nanoparticles is 5:1, the pH value was adjusted to 8, the reaction temperature was 10°C, and the reaction was carried out for 18 hours.

[0041] (3) The solution in step (2) was centrifuged and dried, and the powder of ferric oxide coated with silicon dioxide and polyvinylidene fluoride was mixed in a ratio of 3:1, dissolved in N-methylpyrrolidone, and stirred for 18 hours Then vacuum dry.

[0042] (4) The powder obtained in step (3) is heat-treated in an argon atmosphere at 400° C. for 180 minutes to obtain a composite structure of iron sesquioxide wrapped in silicon dioxide wrapped in carbon.

[0043] (5) Dissolving the powder of the composite structure obtained in step (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com