Manufacturing method of mahogany furniture

A manufacturing method and technology for mahogany furniture, applied in the field of furniture manufacturing, can solve the problems of deformation, easy oxidation of mahogany furniture, affecting the beauty and collection value of mahogany furniture, etc., and achieve the effects of improving stability and preventing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

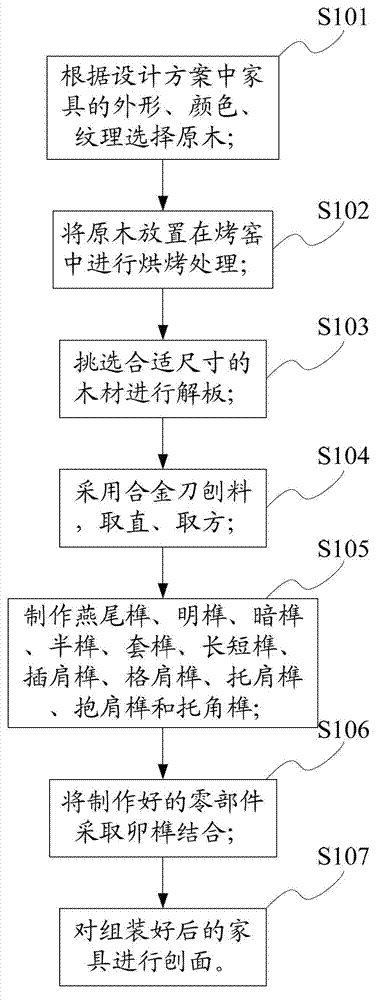

Image

Examples

Embodiment Construction

[0025] Mahogany furniture flourished in the Ming Dynasty and has a long history. It should be noted here that the "mahogany" in mahogany furniture does not refer to all red wood in general, nor is it a kind of wood, but the current domestic general term for mahogany furniture materials. According to the definition of national standards, mahogany furniture refers to furniture made of core materials of 5 genera and 8 types of wood: 5 genera are named after the genus of dendrology, they are red sandalwood, Dalbergia, japonica, iron Knife wood and Persimmon genus; 8 types are named after the trade name of wood, they are red sandalwood, rosewood, fragrant wood, black rosewood, red rosewood, chicken wing wood , ebony and striped ebony; the core material refers to the center of the tree, the part without living cells, and its texture is firmer and denser than the sapwood. Furniture made of other woods cannot be called mahogany furniture.

[0026] Hereinafter, an embodiment will be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com