Production method of magnesium alloy hub

A magnesium alloy and hub technology, which is applied in the field of magnesium alloy hub preparation, can solve problems such as low material utilization, long production cycle, and complex process flow, and achieve the effects of improving comprehensive mechanical properties, reducing production processes, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

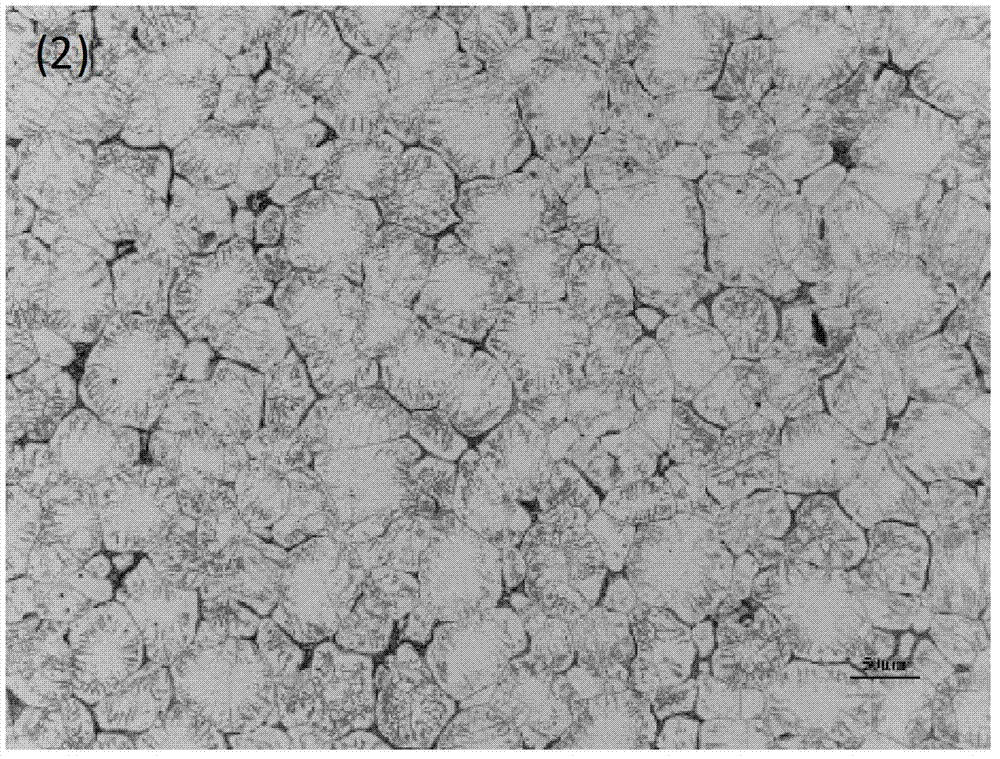

Image

Examples

Embodiment 1

[0021] Embodiment 1, combining figure 1 , figure 2 and image 3 As shown, the composite forming technology in the present embodiment manufactures the method for magnesium alloy wheel hub, and concrete steps are as follows:

[0022] (1) Use AZ31 magnesium alloy as the manufacturing material of the wheel hub. The AZ31 alloy is smelted according to the composition ratio, and purified through refining, standing still, cooling and iron removal, and other processes. The pouring temperature is 680°C. The melt is poured into the mold through a special pouring system, and the whole pouring process is protected by gas to protect the gas composition. for CO 2 and SF 6 The mixed gas, where SF 6 The concentration is 0.5vol%.

[0023] (2) Heat the squeeze casting mold to 250°C, the squeeze casting pressure is 100MPa per unit area, and the holding time is 60s.

[0024] (3) Homogenize the magnesium alloy at 390°C for 10 hours; after homogenization, heat the magnesium alloy blank to 35...

Embodiment 2

[0027] Embodiment 2, the composite forming technique in the present embodiment manufactures the method for magnesium alloy wheel hub, concrete steps are as follows:

[0028] (1) AZ80 magnesium alloy is used as the manufacturing material of the wheel hub. The AZ80 alloy is smelted according to the composition ratio, and after purification treatment such as refining, standing still, cooling and iron removal, the pouring temperature is 700°C, and the melt is poured into the mold through a special pouring system, and the whole pouring process is protected by gas to protect the gas composition for CO 2 and SF 6 The mixed gas, where SF 6 The concentration is 0.5vol%.

[0029] (2) Heat the squeeze casting mold to 250°C, the squeeze casting pressure is 100MPa per unit area, and the holding time is 60s.

[0030] (3) Homogenize the magnesium alloy at 400°C for 16 hours; after homogenization, heat the magnesium alloy billet to 380°C, heat the forging die to 300°C, apply pressure thro...

Embodiment 3

[0033] Embodiment 3, the composite forming technique in the present embodiment manufactures the method for magnesium alloy wheel hub, concrete steps are as follows:

[0034] (1) Use ZK60A magnesium alloy as the manufacturing material of the wheel hub. The ZK60A alloy is smelted according to the composition ratio, after refining, standing still, cooling and iron removal and other processes of purification, the pouring temperature is 720 ° C, the melt is poured into the mold through a special pouring system, and the whole pouring process is protected by gas to protect the gas composition for CO 2 and SF 6 The mixed gas, where SF 6 The concentration is 0.5vol%.

[0035] (2) Heat the squeeze casting mold to 250°C, the squeeze casting pressure is 100MPa per unit area, and the holding time is 60s.

[0036] (3) Homogenize the magnesium alloy at 400°C for 10 hours; after homogenization, heat the magnesium alloy blank to 380°C, heat the forging die to 300°C, apply pressure through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com