Arc plasma torch

An arc plasma and spray gun technology, applied in the direction of plasma, electrical components, etc., can solve the problems of large consumption of coal resources, easy ablation of electrodes, and difficult ablation of electrodes, so as to reduce the consumption of coal resources and prevent easy protection. The effect of being ablated and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

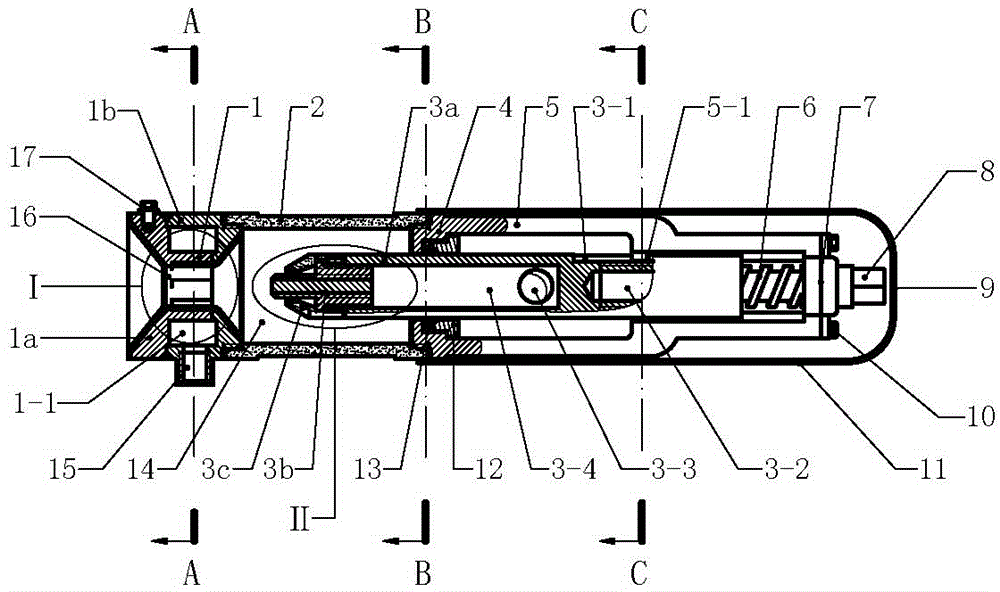

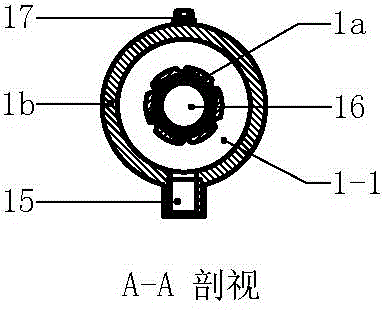

[0030] Example 1 figure 1 In the illustrated embodiment, the arc plasma spray gun is mainly composed of an anode (1), a combined cathode, a gun barrel (2) and a back seat (4), wherein the anode (1), the gun barrel (2) and the back seat (4) Concentric setting, the rear end of the gun barrel (2) is connected to the back seat (4) to form the gun body, the anode (1) is connected to the front end of the gun barrel (2), and the anode (1) is a hollow ring structure, the ring center space of the annular body forms the spout (16), the inner space of the gun barrel (2) forms the air chamber (14), and the rear seat (4) forms the rear closed end of the gun barrel (2); the anode (1) is Hollow ring body structure, there is an annular cooling tank (1-1) in the ring body, the annular cooling tank (1-1) is connected to the cooling water interface (15), the annular cooling tank (1-1) of the anode (1) and the nozzle There are cooling water vaporization holes (1-2) and steam injection grooves (1...

Embodiment 2

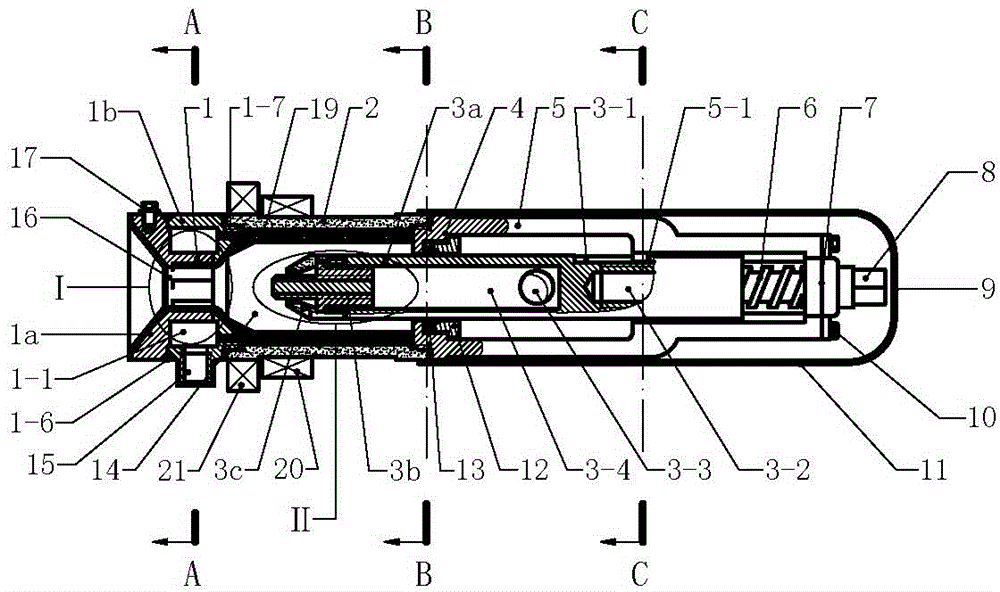

[0031] Example 2 figure 2 In the embodiment shown, there is a bushing (19) inside the air chamber (14), and the bushing (19) is made of zirconia fiber cotton material, and the outer wall of the bushing (19) is closely adjacent to the inner wall of the gun barrel (2) , the two ends of the bushing (19) are respectively adjacent to the anode (1) and the back seat (4), or the two ends of the bushing (19) are respectively adjacent to the anode (1) and the cathode base; the anode (1) and the bushing There is a through hole (1-7) on the anode ring body adjacent to the sleeve (19), and the through hole (1-7) communicates with the annular cooling groove (1-1), and the through hole (1-7) connects the annular cooling groove (1-1) -1) The cooling water is guided to the bushing (19) for adsorption, the cooling water is heated and evaporated into water vapor, and the water vapor is used as working gas or as a heated object. In this embodiment, the purpose of setting the bushing (19) in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com