Gelatinized developing device with clustered structure

A technology of glue developing and equipment, which is applied in the direction of photo-engraving process coating equipment, electrical components, semiconductor/solid-state device manufacturing, etc., to achieve the effects of easy loading and disassembly, reduced machine footprint and strong technical expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

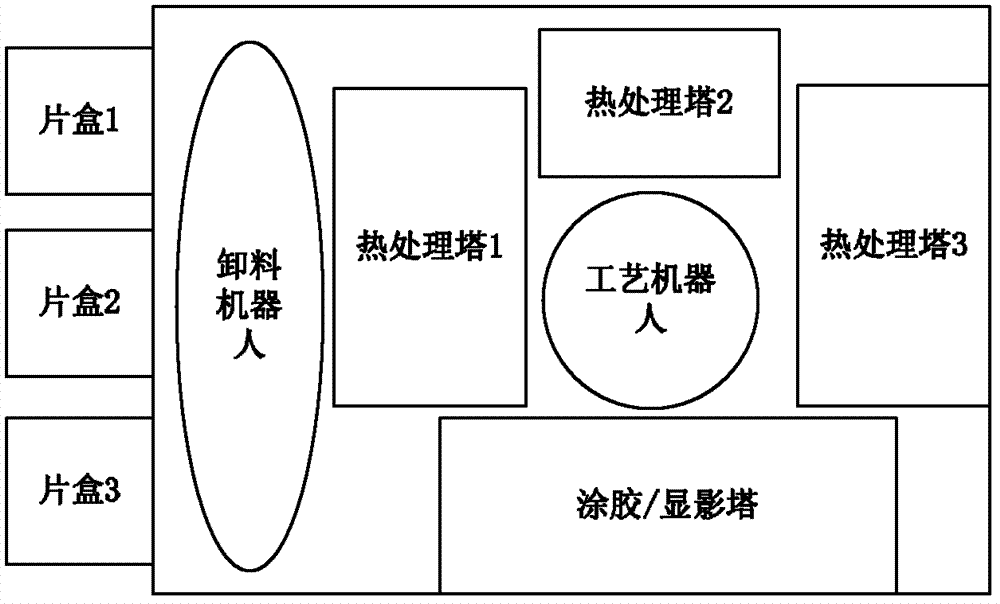

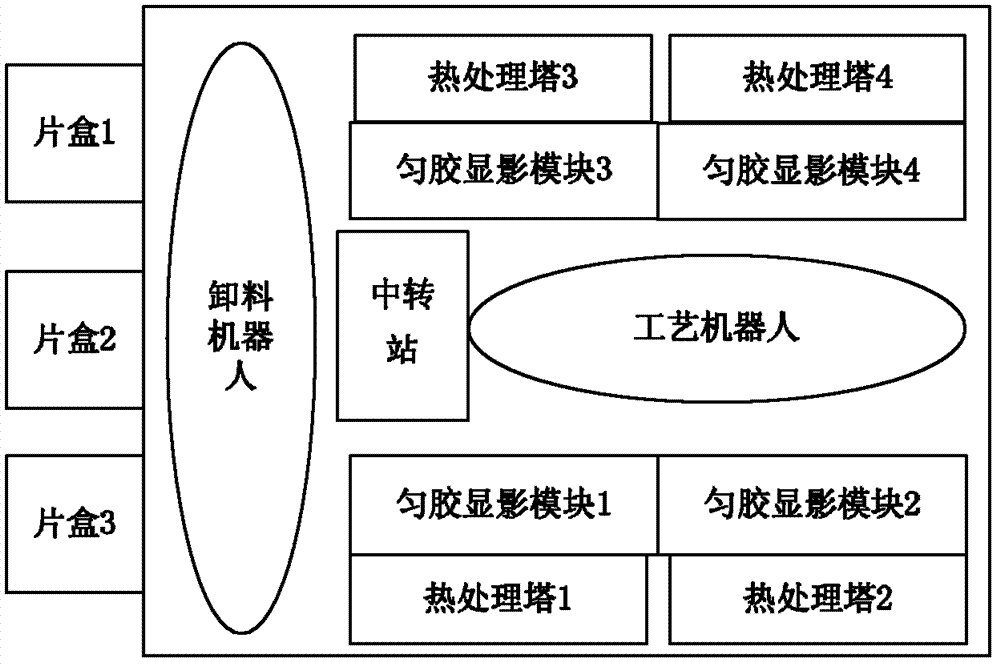

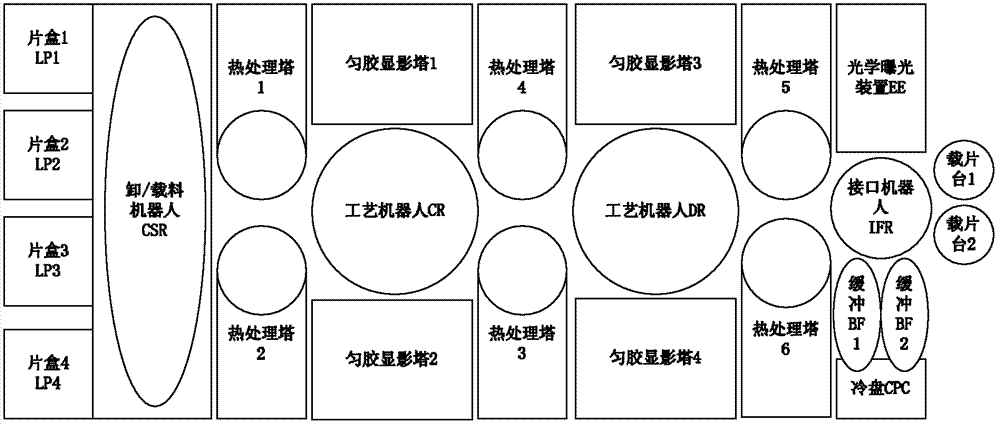

[0027] The structure of the present invention is as image 3 As shown, it includes cassette station, process station and interface station. The cassette station and process station transfer wafers through unloading / loading robots, and the process station and interface station transfer wafers through interface robots. Process stations include photoresist coating stations and developing station, the photoresist coating station and developing station are arranged in a line with the film cassette station and interface station, and the process processing modules in the station are distributed in clusters. DR; 4 heat treatment towers are arranged in four directions of the photoresist coating station, in counterclockwise order: heat treatment tower 1, heat treatment tower 2, heat treatment tower 3 and heat treatment tower 4, heat treatment tower 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com