Method for preparing carbon nanotube composite conductive hydrogel coating modified electrode

A carbon nanotube composite, conductive hydrogel technology, applied in the field of biomedical materials and medical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

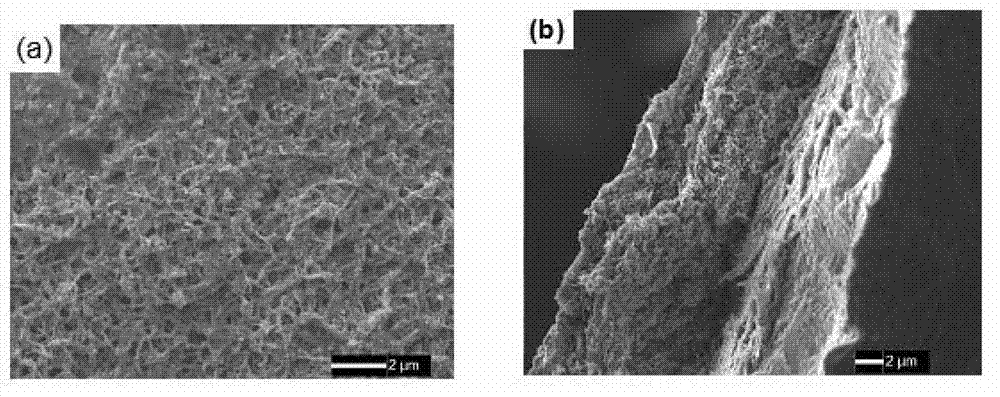

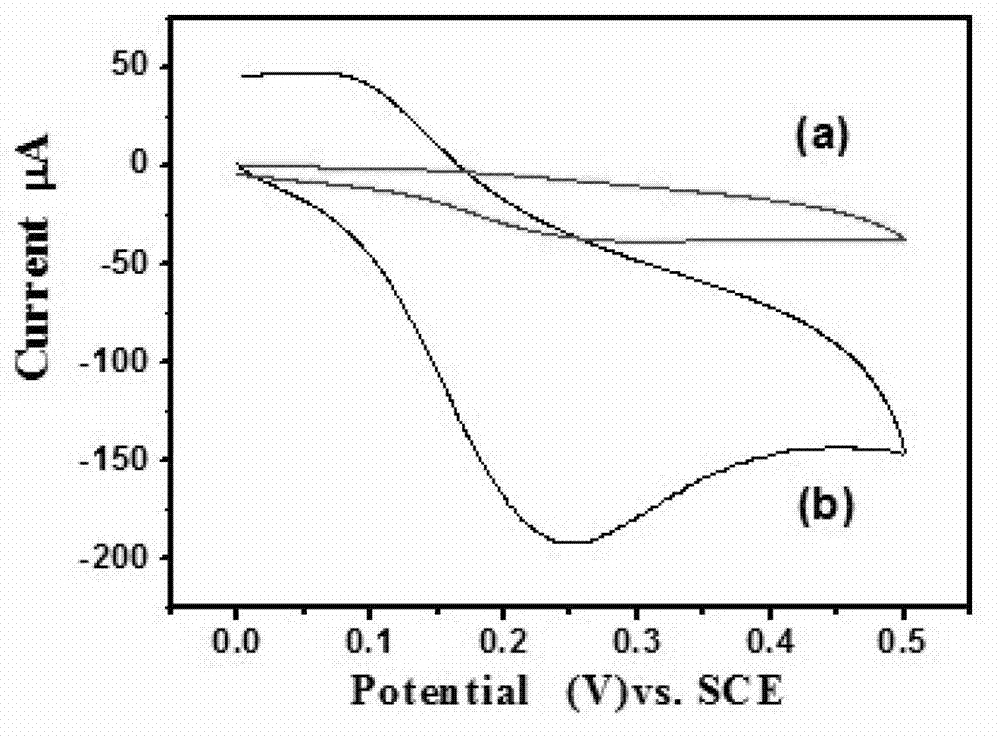

Image

Examples

Embodiment 1

[0039] Step 1, preparation of carbon nanotube dispersion liquid.

[0040] Take 500 mg of multi-walled carbon nanotubes into 200 mL of 30% H 2 o 2 The solution was sonicated for 30 min, and then refluxed at 60 °C for 1 h. The resulting solution was vacuum filtered through a 0.2 μm polyvinylidene fluoride membrane. Wash the filtered carbon nanotubes with deionized water until neutral, and then put them into a vacuum drying oven for drying. Add the dried carbon tubes into 40 mL of mixed acid solution containing concentrated sulfuric acid and concentrated nitric acid (vH 2 SO 4 : vHNO 3 =3:1) were subjected to magnetic stirring for 1 hour, and then ultrasonically dispersed at 60 °C for 4 hours. The resulting dispersion is centrifuged to remove excess acid, and the centrifuged carbon nanotubes are washed with a large amount of deionized water until neutral. Finally, vacuum-dry at 80°C to obtain the required acidified carbon tubes.

[0041] Take 20 mg of acidified carbon nan...

Embodiment 2

[0051] Step 1, preparation of carbon nanotube dispersion liquid.

[0052] Weigh 40 mg of anionic surfactant sodium dodecylbenzene sulfonate and dissolve it in 30 mL of deionized water, and make it fully dissolved by magnetic stirring. After the dissolution is complete, 30 mg of carbon nanotube solid powder is slowly added while continuing magnetic stirring, so that the carbon nanotubes are fully dispersed in the surfactant solution. After magnetic stirring for 40 minutes, ultrasonic dispersion was used for 3 hours to obtain a uniform and stable carbon nanotube dispersion.

[0053] Step 2, preparation of carbon nanotube / hyaluronic acid composite sol.

[0054] Accurately weigh 3 g of hyaluronic acid, add 100 g of deionized water and stir with a magnetic stirrer to fully dissolve the solute hyaluronic acid at 80°C to obtain a hyaluronic acid sol with a concentration of 3%; continue magnetic stirring, The carbon nanotube dispersion was slowly added dropwise into the hyaluronic a...

Embodiment 3

[0061] Step 1, preparation of carbon nanotube dispersion liquid.

[0062] The carbon nanotubes were dispersed with the cationic surfactant cetyltrimethylammonium bromide. Weigh 40 mg of cetyltrimethylammonium bromide and dissolve it in 40 mL of deionized water, and make it fully dissolved by magnetic stirring. After the dissolution is complete, continue magnetic stirring while slowly adding 20 mg of carbon nanotube solid powder to fully disperse the carbon nanotubes in the surfactant solution. After magnetic stirring for 30 minutes, ultrasonic dispersion was used for 3 hours to obtain a uniform and stable carbon nanotube dispersion.

[0063] Step 2, preparation of carbon nanotube / sodium alginate composite sol.

[0064] Accurately weigh 2 g of sodium alginate, add 100 g of deionized water and stir with a magnetic stirrer to fully dissolve the solute sodium alginate at 80°C to obtain a sodium alginate sol with a concentration of 2%; continue magnetic stirring, and The carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com