Undersized log light wood structure composite shear wall

A combination of shear walls and small-diameter wood technology, applied to walls, building components, building structures, etc., can solve the problems of low price and poor economic benefits of small-diameter wood, and achieve the goal of reducing construction costs, reducing usage, and facilitating installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

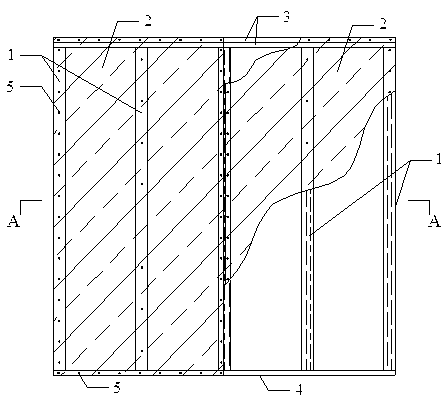

[0025] Such as figure 1 and figure 2 As shown, a small-diameter wooden light-weight wood-structure composite shear wall involved in this embodiment includes a small-diameter wooden composite wall stud 1, a wood-based structural board 2, a top beam board 3, a bottom beam board 4, and a gypsum board 6. The small-diameter composite wall studs 1 are arranged vertically, and two adjacent small-diameter composite wall studs 1 are parallel to each other. In the bottom beam plate 4, the wall skeleton is composed of the small-diameter wood composite wall stud 1, the top beam plate 3 and the bottom beam plate 4, and a wood-based structural plate 2 is fixed on one side of the wall skeleton. The other side of body skeleton is fixed with gypsum board 6.

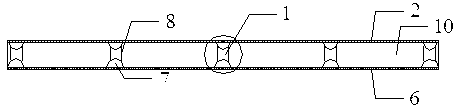

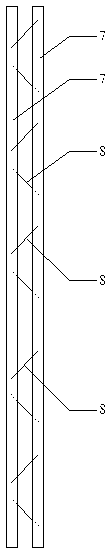

[0026] Such as Figure 2~Figure 5 As shown, the small-diameter wooden composite wall stud 1 is composed of two small-diameter wooden column limbs 7 and C-shaped nails (screwing nails) 8 , and the two small-diameter wooden column limbs...

Embodiment 2

[0034] The difference from Embodiment 1 is that after the specification and size of the shear wall are determined, the raw materials are transported to the construction site, and the fabrication and installation of the shear wall are completed on site.

Embodiment 3

[0036] Such as Figure 6 As shown, in the vicinity of wall corners and door and window openings, in order to facilitate wall layout and door and window installation, some small-diameter wood composite studs are replaced with standard timber studs 9 . Figure 6 is an example of dimension lumber for side studs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com