Method for preparing magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition

A micro-arc oxidation and electrophoretic deposition technology, which is applied in coating, anodizing, electrolytic coating, etc., can solve the problems of poor bonding force, affecting the application of bioceramic coating materials, and weak corrosion resistance, and achieve coating The effect of increased toughness, improved adhesion, and enhanced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

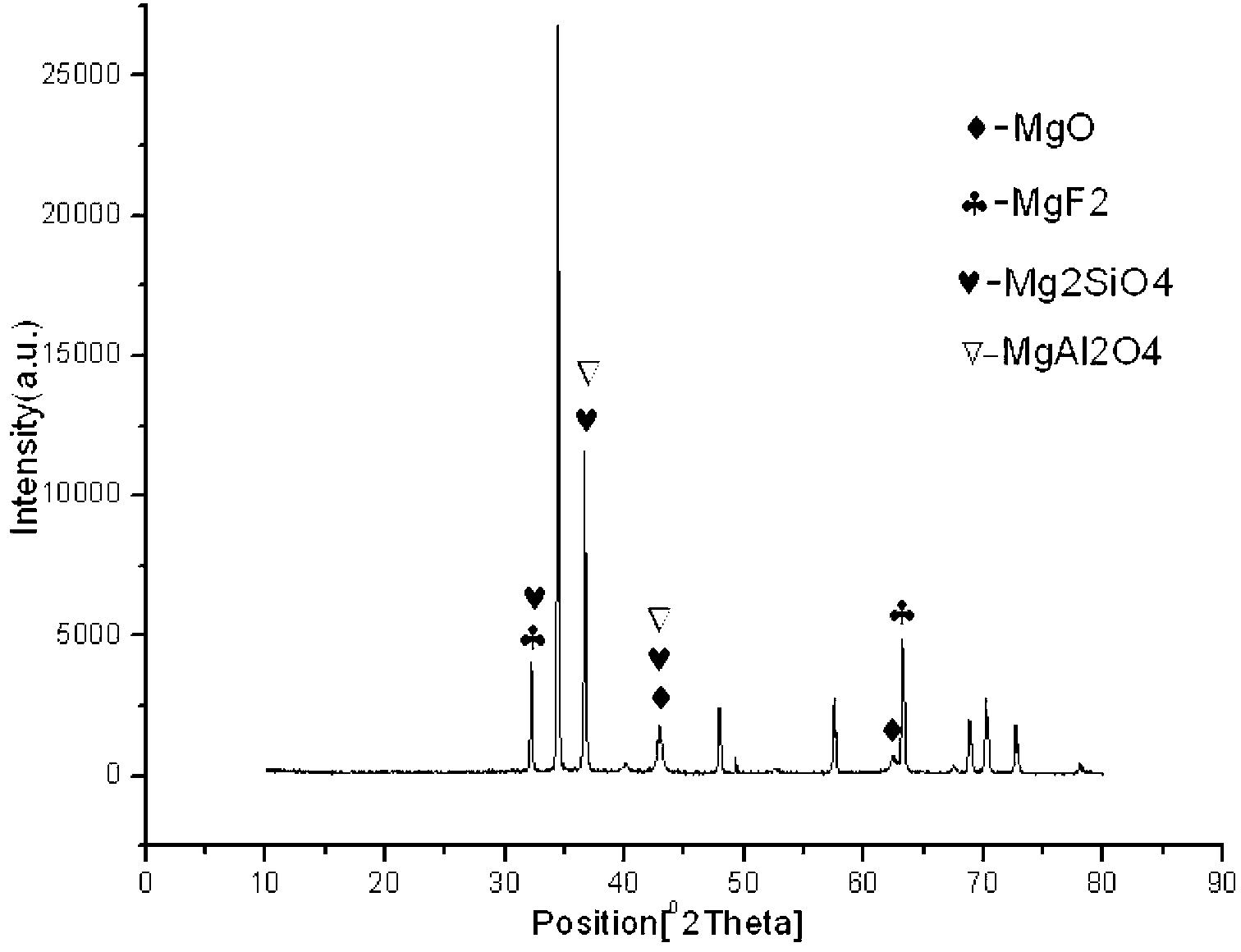

[0030] Example 1: Magnesium-based ceramic coating prepared by micro-arc oxidation method in electrolyte without adding nanopowder

[0031] Electrolyte final concentration composition: Na 2 SiO 3 10H2 O17.5g, NaF10.0g, NaOH5.5g, 3ml ethylene glycol, deionized water 1L.

[0032] (1) Pretreatment: AZ31B magnesium alloy 60mm×20mm×2mm is made into a rectangular sheet, polished with 280#, 500#, 800#, 1200# metallographic sandpaper to remove surface oxides, and then placed in absolute ethanol Perform ultrasonic cleaning for 5-10 minutes, and dry naturally at room temperature to obtain the pretreated magnesium alloy;

[0033] (2) Micro-arc oxidation: immerse the pretreated magnesium alloy obtained in step (1) as an anode in the electrolyte, use a micro-arc oxidation stainless steel electrolytic cell as a cathode, and use a 30kW DC pulse micro-arc oxidation device at a current of 10A / dm 2 , with a duty ratio of 37.5%, micro-arc oxidation for 10 minutes at an electrolyte temperature ...

Embodiment 2

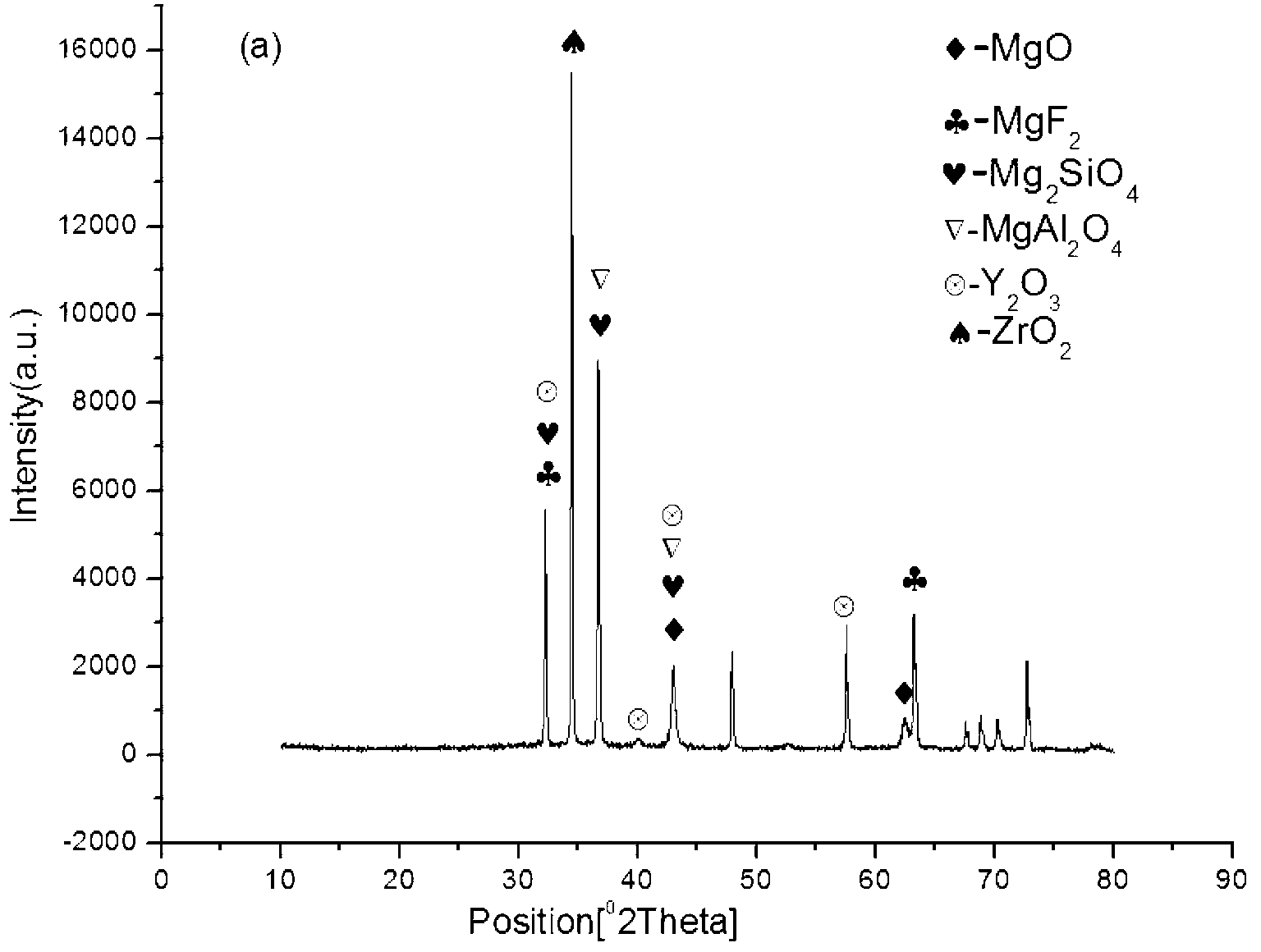

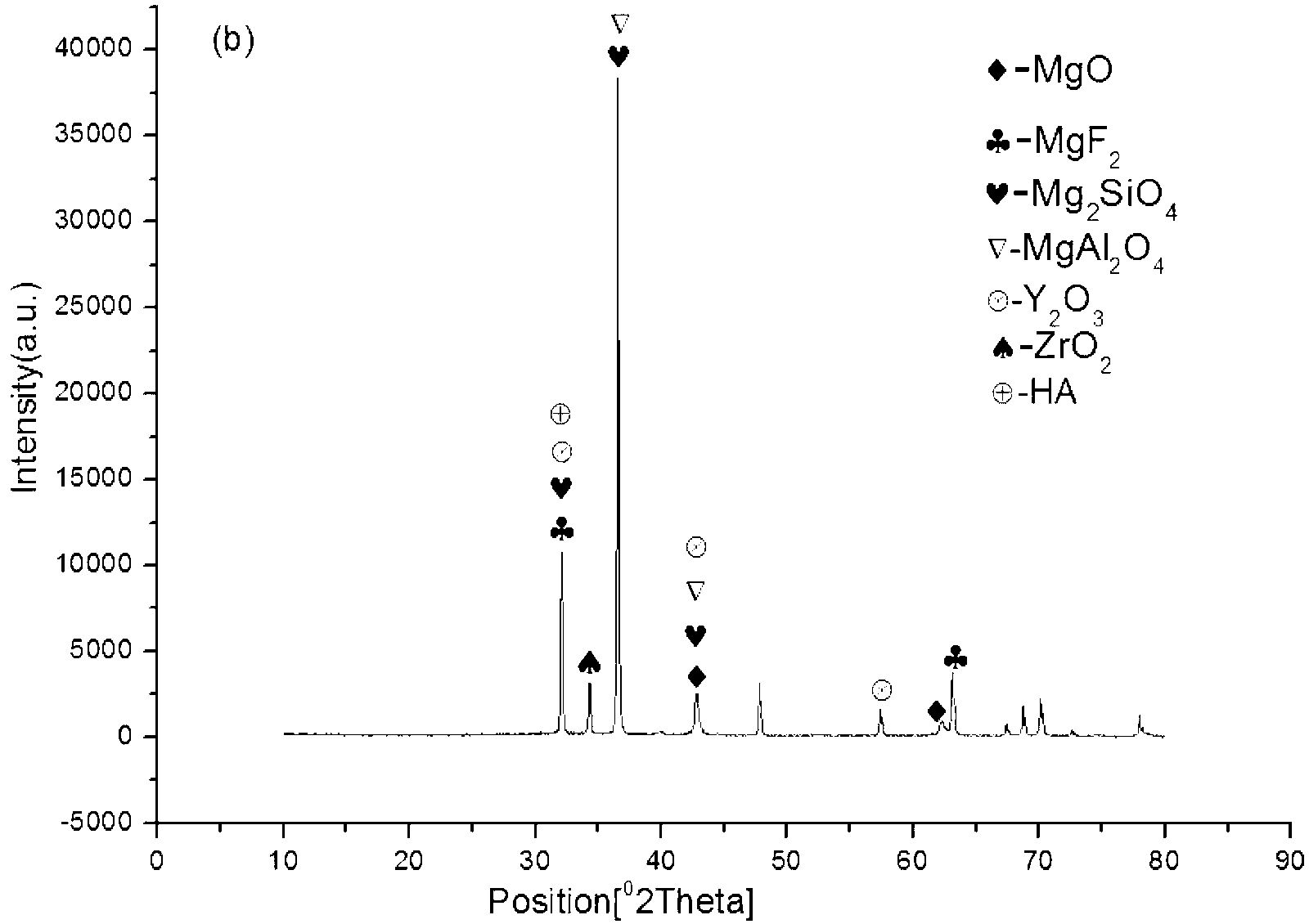

[0034] Example 2 Magnesium-based Ceramic Coating Prepared by Micro-arc Oxidation in Electrolyte Added with Nano Powder

[0035] Electrolyte: Y 2 o 3 Nano powder (100nm) 1.0g, ZrO 2 Nano powder (50nm) 5g, Na 2 SiO 3 10H 2 O17.5g, NaF10.0g, NaOH5.5g, 3ml ethylene glycol, deionized water 1L, stir to form a suspension when used.

[0036] Electrophoretic deposition solution: Na 3 PO 4 10.0g, 3.0g HA nanopowder (100nm), 3ml ethylene glycol, 1L deionized water, stir with a magnetic stirrer for 2h, then age for 6h, and use the aged anionic turbid upper layer as the electrophoretic deposition solution.

[0037] The final concentration of simulated body fluid consists of (solvent is deionized water):

[0038]

[0039] (1) Pretreatment: AZ31B magnesium alloy 60mm×20mm×2mm is made into a rectangular sheet, polished with 280#, 500#, 800#, 1200# metallographic sandpaper to remove surface oxides, and then placed in absolute ethanol Perform ultrasonic cleaning for 5-10 minutes, an...

Embodiment 3

[0044] The difference from Example 1 is that the micro-arc oxidation treatment time is 20min, 10ml ethylene glycol, and other operations are the same as in Example 1 to prepare a magnesium alloy micro-arc oxidation ceramic coating. The results show that: the main phase of the coating is: MgO, MgF 2 , Mg 2 SiO 4 and MgAl 2 o 4 . The surface micro-morphology of the micro-arc oxidation ceramic coating shows that the diameter of micropores on the surface of the coating is larger than that in Example 1, the number of micropores is reduced, and the number of microcracks is increased. However, the thickness of the coating is increased, and the corrosion resistance is enhanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com