Method for preparing polyether glycol by liquefying starch

A polyether polyol and starch liquefaction technology, applied in the direction of organic chemistry, can solve the problems of low yield of liquefied products, high pressure resistance requirements of equipment, corrosion of metal reactors, etc., to solve environmental pollution and equipment corrosion and liquefaction. The effect of high rate and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5-8

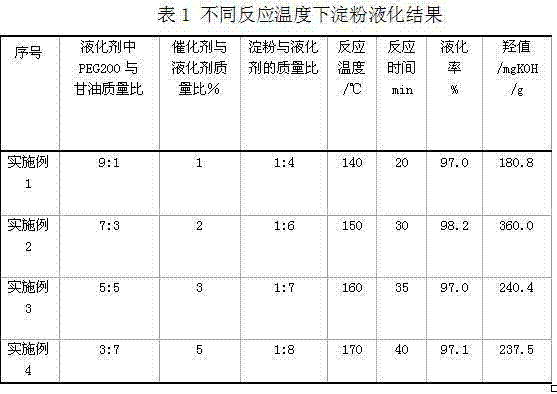

[0041] Example 5-8: Preparation of polyether polyols at different times

[0042] The raw material of embodiment 5-8 uses cornstarch, and all the other are respectively with embodiment 1-4. The liquefaction results are listed in Table 2.

[0043] serial number time / min Liquefaction % Hydroxyl value / mgKOH / g Example 5 20 97.5 180.1 Example 6 30 98.2 360.0 Example 7 35 97.8 240.6 Example 8 40 97.1 137. 5

[0044] Note: the obtained polyether polyol characterization method is exactly the same as that of Example 1-4, so it is omitted here.

Embodiment 9-13

[0045] Example 9-13: Preparation of polyether polyols with different ratios of liquefiers

[0046] Mung bean starch was used as the raw material in Examples 9-13, and the mass ratios of PEG200 and glycerin in the liquefier were 9:1, 7:3, 5:5, 3:7, and 1:9. The liquefaction results are listed in Table 3.

[0047] serial number PEG200: Glycerin Liquefaction % Hydroxyl value / mgKOH / g Example 9 9:1 96.2 124.5 Example 10 7:3 98.2 360.0 Example 11 5:5 97.4 123.4 Example 12 3:7 97.3 126.2 Example 13 1:9 97.1 128.5

[0048]Note: the obtained polyether polyol characterization method is exactly the same as that of Example 1-4, so it is omitted here.

Embodiment 14-16

[0049] Example 14-16: Preparation of polyether polyols with different amounts of liquefiers

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Average apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com