Narrow flow induction coupling chemical vapor deposition (CVD) densification method for rapidly preparing carbon/carbon composite material crucible

A carbon composite material and inductively coupled technology, applied in the field of narrow-flow inductively coupled CVD densification, can solve the problems of low densification efficiency, long preparation cycle, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A carbon / carbon composite crucible for pulling silicon single crystal material was prepared, the crucible size was Φ500×450mm.

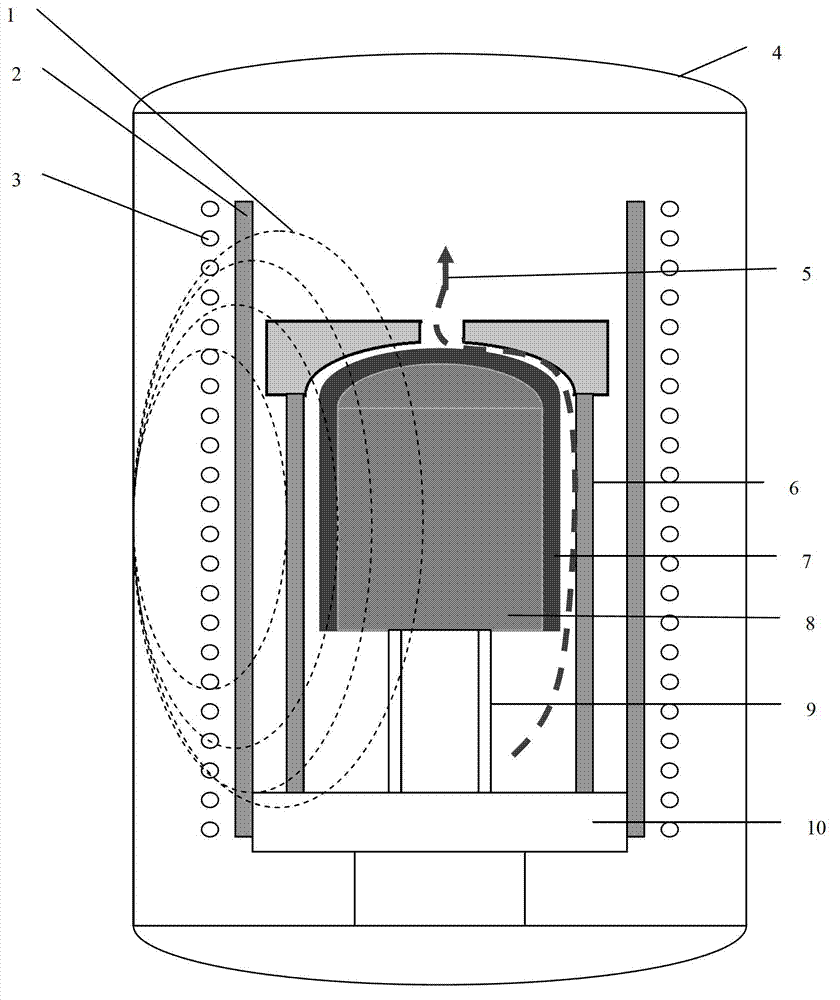

[0039] (1) Put the carbon fiber braided crucible preform, inductive coupling tooling, and airflow tool in the reaction chamber of the vacuum induction deposition furnace. The crucible preform is sleeved on the inductive coupling tooling, and then covered with the airflow tooling, the preform and the inductive coupling tooling, The gas flow tooling is matched to form a 50mm wide gas flow channel and the whole inner surface of the crucible preform cylinder section is inductively coupled;

[0040] The inductive coupling tool is a coupling graphite core, and the air flow tool is made of electrode graphite.

[0041] (2) Increase the temperature and vacuum, when the temperature reaches 950℃, the vacuum degree is 1000Pa, and the temperature is kept for 20min;

[0042] (3) Then use nitrogen as the protective dilution gas, press propylene: N 2 =1:1 volume rati...

Embodiment 2

[0045] Example 2. Preparation of a carbon / carbon composite crucible for purifying and smelting polysilicon, the crucible size is Φ600×600mm.

[0046] (1) Place the carbon fiber cloth mesh needle-punched crucible preform and tooling in the reaction chamber of the vacuum induction deposition furnace. The preform is matched with the induction coupling tooling and airflow tooling to form a 30mm wide gas flow channel and the crucible barrel section for inductive coupling on the entire inner surface ;

[0047] (2) Increase the temperature and vacuum, when the temperature reaches 1250℃, the vacuum degree is 2000Pa, and the temperature is kept for 30min;

[0048] (3) Then use nitrogen as the protective diluent gas, press methane: N 2 =2:1 volume ratio of methane and N 2 The gas flows into the reaction chamber of step (1), N 2 The air flow is 1000ml / min, the aeration infiltration reaction is 120h, and the carbon matrix is formed by in-situ pyrolysis and deposition;

[0049] (4) After cooling...

Embodiment 3

[0051] Example 3. A carbon / carbon composite crucible for polycrystalline silicon ingots was prepared, the crucible size was 800×800×600 mm.

[0052] (1) Place the carbon fiber cloth laminated crucible preform and tooling in the reaction chamber of the vacuum induction deposition furnace. The preform is matched with the inductive coupling tooling and airflow tooling to form a 10mm wide gas flow channel and the crucible barrel section for inductive coupling on the entire inner surface;

[0053] (2) Heat up and vacuum, when the temperature reaches 1150℃, keep the temperature for 30min under the condition of 4000Pa vacuum;

[0054] (3) Then use nitrogen as the protective dilution gas, press liquefied petroleum gas: N 2 =1:2 volume ratio will be liquefied petroleum gas and N 2 The gas flows into the reaction chamber of step (1), N 2 The air flow is 3000ml / min, the aeration permeation reaction is 180h, and the carbon matrix is formed by in-situ pyrolysis and deposition;

[0055] (4) After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com