Preparation method of spiral titanium dioxide (TiO2) nano wire doped with silver/silver chloride (Ag/AgCl)

A helical and nanowire technology, applied in the field of preparation of helical TiO2 nanowires, can solve the problems of reducing the speed of photocatalytic degradation of organic pollutants, affecting the scope of use, low quantum yield, etc., and achieving accelerated photocatalytic degradation of organic pollutants. process, fast catalytic degradation, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A Helical TiO Doped with Ag / AgCl 2 Nanowires, prepared by:

[0030] (1) Take 0.03g of glutamic acid with 18 carbon chains (C 18-D- Glu), dissolved in a mixed solution of 13.6g of methanol and 80mL of water, at room temperature, the reaction time is 10min;

[0031] (2) Take 0.29g of titanium diisopropoxybisacetylacetonate, add the mixed solution obtained in step (1), and stir for 2 hours at 55°C;

[0032] (3) 10000r / min, centrifuge the mixture obtained in step (2) for 15min to obtain a colloid, and freeze-dry at -60°C for 12h to obtain a light yellow powder;

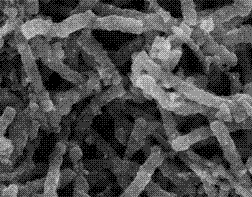

[0033] (4) At 550°C, calcinate the light yellow powder for 6 hours to obtain helical TiO 2 nanowires, the resulting schematic diagram is shown in figure 1 shown;

[0034] (5) Take 0.2g TiO 2 Mix the nanowires with 0.3g cetyltrimethylammonium chloride and 100mL water, and stir for 1h at room temperature;

[0035] (6) Add AgNO to the mixture obtained in step (5) 3 (2mL, 1.0M), stirred at room temperature for ...

Embodiment 2

[0040] Take 500mL of sewage with a 17β-estradiol concentration of 0.5mg / L, and put 0.25g of Ag / AgCl-doped helical TiO under the irradiation of a 24W fluorescent lamp. 2 The nanowires (prepared in Example 1), after 10 minutes, have a degradation rate of 99% for 17β-estradiol, while the degradation rate for common P25 is 20%. While ordinary helical TiO 2 It takes 80 minutes for nanowires to achieve a 99% degradation rate under the same conditions of light intensity and pollutant concentration. Therefore, it can be said that the helical TiO doped with Ag / AgCl 2 The nanowires significantly improved the removal of 17β-estradiol.

Embodiment 3

[0042] A Helical TiO Doped with Ag / AgCl 2 Nanowires, prepared by:

[0043] (1) Take 0.1mol of glutamic acid with eighteen carbon chains (C 18-D-Glu), dissolved in a mixed solution of 380mol methanol and 5596.2mol water, at room temperature, the reaction time is 15min;

[0044] (2) Take 0.5 mol of titanium diisopropoxybisacetylacetonate, add the mixture obtained in step (1), and stir for 2.5 hours at 56°C;

[0045] (3) 10000r / min, centrifuge the mixture obtained in step (2) for 15min to obtain a colloid, and freeze-dry at -60°C for 12h to obtain a light yellow powder;

[0046] (4) Calcining light yellow powder at 600°C for 8 hours to obtain helical TiO 2 Nanowires;

[0047] (5) Take 0.2g TiO 2 Mix the nanowires with 0.3g cetyltrimethylammonium chloride and 100mL water, and stir for 1.5h at room temperature;

[0048] (6) Add AgNO to the mixture obtained in step (5) 3 (2mL, 1.0M), stirred at room temperature for 1.5h, and then continued to stir for 1.5h under the irradiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com