Aqueous polishing composition and process for chemically mechanically polishing substrate materials for electrical, mechanical and optical devices

A composition and water polishing technology, applied in the direction of chemical instruments and methods, polishing compositions containing abrasives, polishing compositions, etc., can solve problems such as oxide-nitride selectivity that are not mentioned, and achieve improved process management , to improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

preparation example Construction

[0138] The preparation of the composition of the present invention does not show any particularity, but can be achieved by dissolving or dispersing the above-mentioned components (A), (B) and (C) and optionally (D) and / or (E) in an aqueous medium, especially performed in deionized water. For this purpose, customary and standard mixing methods and mixing devices can be used, such as stirred vessels, in-line dissolvers, high-shear impellers, ultrasonic mixers, homogenizer nozzles or countercurrent mixers. The composition according to the invention thus obtained may preferably be filtered through a filter having suitable mesh openings in order to remove coarse particles, such as solid aggregates or agglomerates of finely divided abrasive particles (A).

[0139] The compositions of the invention are extremely suitable for the method of the invention.

[0140] In the method of the invention, substrate materials for electronic, mechanical and optical devices, especially electronic ...

example 20-22

[0166] - Substrates: 2000nm thermal silica coated blank wafers from SKW and 500nm silicon nitride coated blank wafers from Montco Silicon; Examples 20-22: TEOS silica coated blank wafers;

[0167] - Downward force: 3.5 psi (240 mbar);

[0168] - Polishing time: 1 minute.

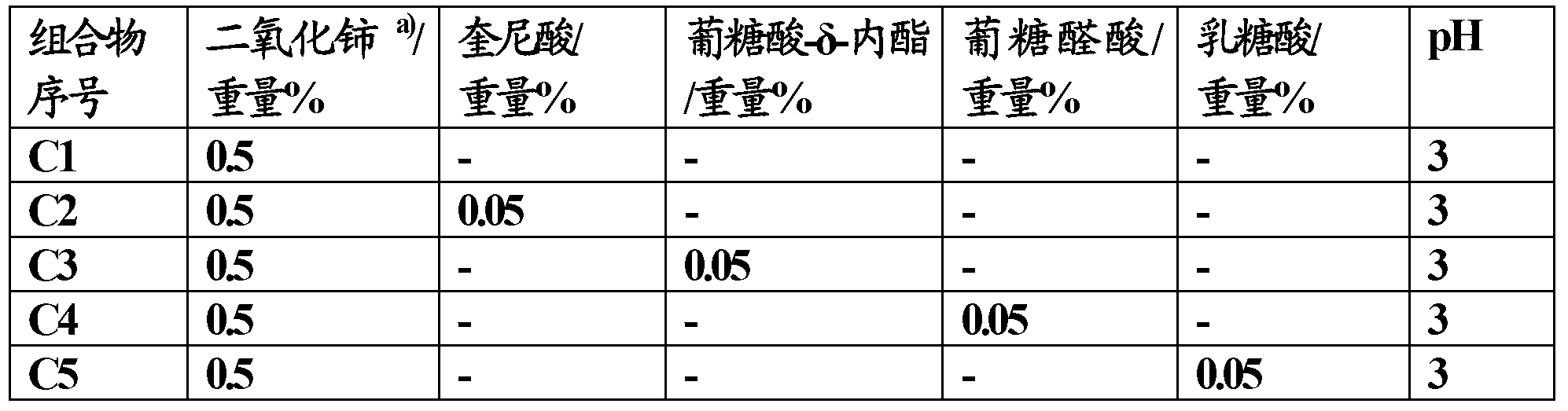

[0169] The material removal rate MRR was measured with a reflectometer. The results obtained are compiled in Table 2.

[0170]Table 2: CMP and Oxide-Nitride Selectivity of SiO2-Coated Blank Wafers and SiN-Coated Blank Wafers

[0171]

[0172] a) Angstroms / minute

[0173] The results, compiled in Table 2, show that high oxide-nitride selectivities can be obtained in the sole presence of hydroxycarboxylic acids and hydroxyl-containing lactones. However, the comparative aqueous polishing compositions containing only these additives required much improvement in terms of pitting and overpolishing of the trench oxide in the STI process and dispersion stability (pot life).

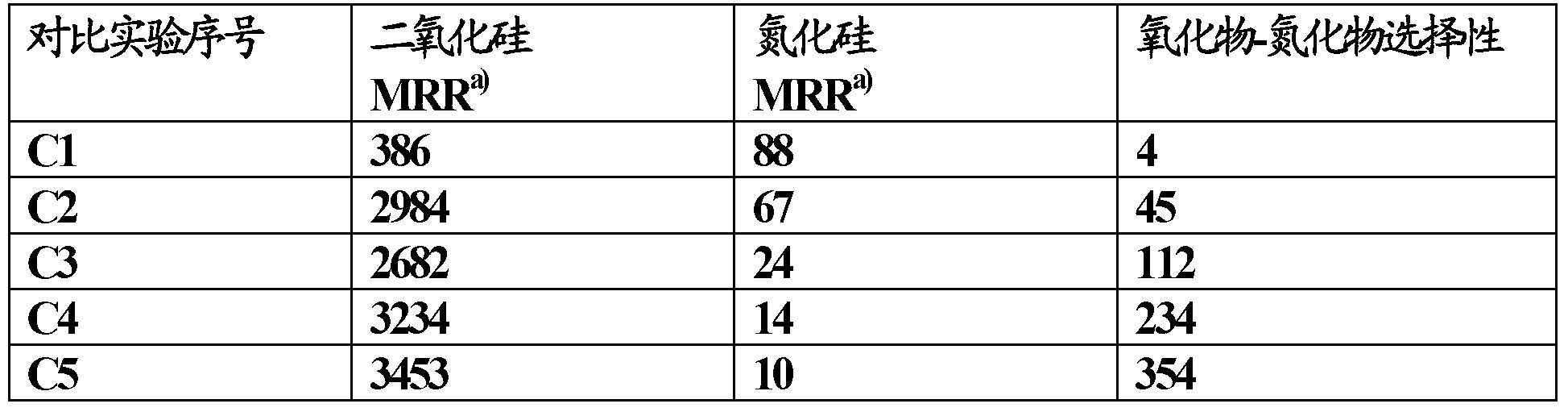

[0174] Examples 1-4 and Comparat...

Embodiment 5

[0201] Stabilization of ceria-based aqueous polishing compositions with cationically modified flocculants

[0202] Cationic modified flocculant (Sedipur TM CL520, ex BASF SE) was added in various amounts to an aqueous polishing composition having a pH of 3 and containing 0.5% by weight ceria and 0.025% by weight glucuronic acid. Average particle size was measured with a Horiba Instrument particle size analyzer. The results obtained are compiled in Table 5.

[0203] Table 5: With Sedipur TM Stabilization of ceria-based aqueous polishing compositions for CL520

[0204] Sedipur TM Concentration of CL520 / ppm

[0205] Table 5 shows that the addition of even as low as 10 ppm is sufficient to control the aggregation of ceria particles, thereby enhancing the stability of the aqueous polishing composition and its shelf life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com