Reagent device for detecting antinuclear antibody and method thereof

A technology for antinuclear antibodies and detection reagents, which is applied in the field of clinical immunology detection, can solve problems such as the need to improve sensitivity, poor accuracy and precision of detection results, cumbersome and complicated operation process, and meet the short time of detection results and use requirements Low, highly specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

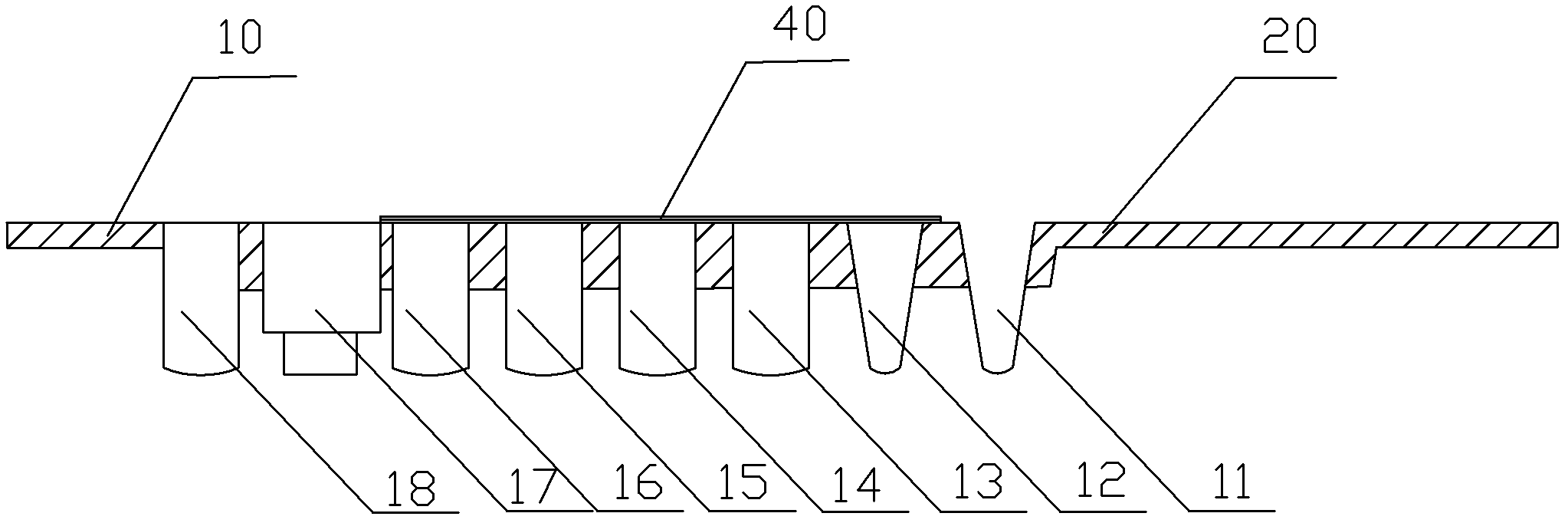

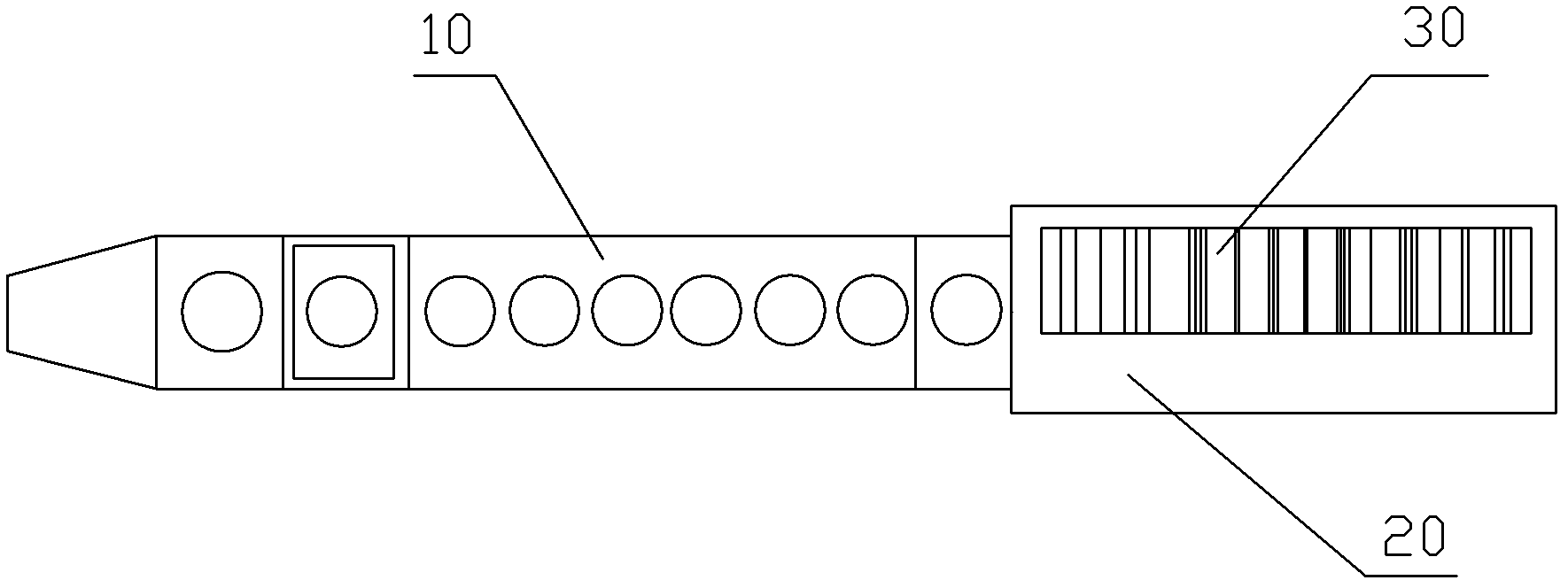

[0103] Embodiment one detection antinuclear antibody reagent device one

[0104] like Figure 1-2 As shown, the reagent device for detecting anti-nuclear antibodies described in the application of the present invention is in the shape of a strip, including a base body 10 with eight holes and a handle 20 positioned at one end of the base body 10, and the arrangement order of the eight holes starts from near the handle 10 Starting from the end, there are sample wells 11, auxiliary agent wells 12, enzyme conjugate wells 13, substrate wells 14, stop solution wells 15, diluent wells 16, reaction wells 17 and dilution wells 18. The sample wells 11 contain There is a sample to be tested, and the auxiliary agent hole 12 is used for adding auxiliary reagents when detection is required. In the detection method described in the present application, no reagent is added in the auxiliary agent hole 12, and an enzyme conjugate solution is added in the enzyme conjugate hole 13. Substrate sol...

Embodiment 2

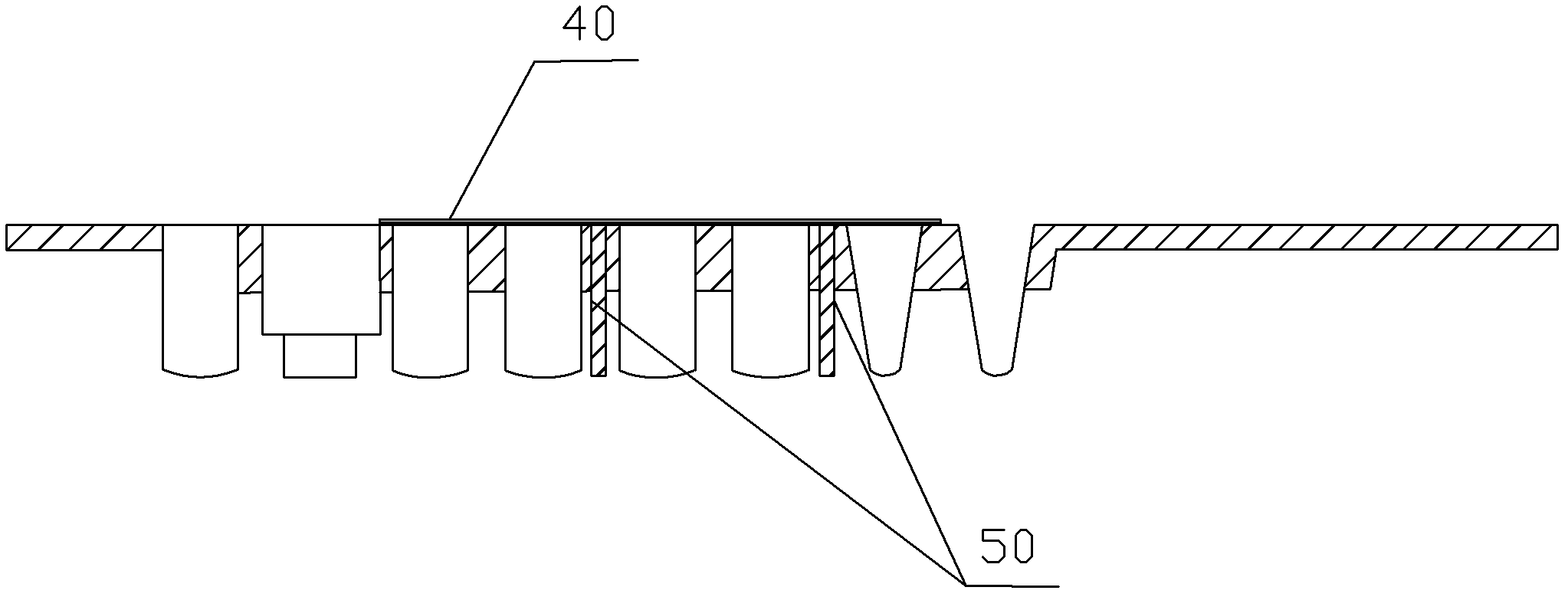

[0107] Embodiment two detects the reagent device two of antinuclear antibody

[0108] like image 3 As shown, the reagent device for detecting antinuclear antibodies in this embodiment has the same basic structure as that of the reagent device in Example 1, and the reagent device also includes several support columns 50, and the support columns 50 are located at the Under the substrate 10 in the above reagent device, there is more than one hole between adjacent supporting pillars 50. The function of the supporting pillars 50 is to enhance the mechanical strength and balance of the substrate.

Embodiment 3

[0109] Embodiment three detects the reagent device three of antinuclear antibody

[0110] like Figure 4-6 As shown, it is a preferred embodiment of the reagent device for detecting antinuclear antibodies described in the application of the present invention. Its basic structure is the same as that of Embodiment 1 or Embodiment 2, except that the reaction hole 17 is a detachable structure, and the reaction hole 17 is a detachable structure. Consists of an outer hole 171 and an inner hole 172, the bottom of the outer hole 171 is provided with a bottom hole 174, the inner hole 172 passes through the bottom hole 174 and closely fits with the bottom hole 174, and there is an anti-overflow gap between the outer hole 171 and the inner hole 172 Cavity 173, the function of the anti-overflow cavity 173 is that during the reaction, if the liquid overflows, it can stay in the cavity to prevent contamination of instruments and other reagent devices.

[0111] Further, the cooperating fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com