Polyethylene steel and plastic composite winding pipe

A steel-plastic composite and polyethylene technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of low creep, heavy weight, easy leakage, etc., and achieve improved corrosion resistance. The level of resistance to internal pressure and the effect of facilitating construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

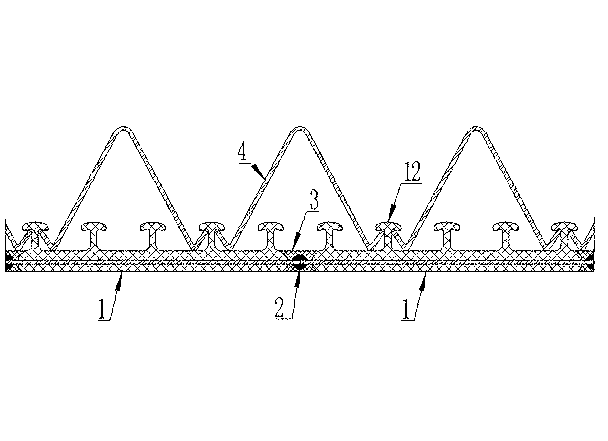

[0012] Such as figure 1 As shown, the pipe body of the polyethylene steel-plastic composite winding pipe is formed by winding the steel-plastic composite board strip 1, and the adjacent steel-plastic composite board strips 1 are welded by metal electric welding process, and the polyethylene resin coating layer 3 is wrapped on the welding line 2 between the adjacent steel-plastic composite plate strips 1, and the V-shaped reinforced steel ribs 4 rolled by galvanized steel strips are embedded between the T-shaped caps 12 on the outer wall of the pipe.

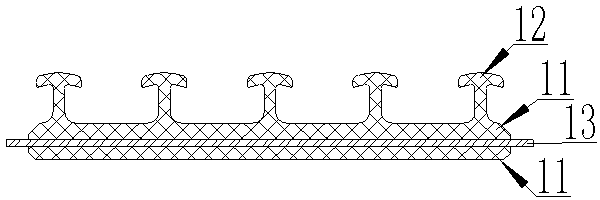

[0013] Such as figure 2 As shown, the main body of the steel-plastic composite board strip 1 is a flat wall structure of a polyethylene matrix. Four T-shaped caps 12 are arranged on the upper side of the flat wall 11. The lower side of the flat wall 11 is smooth, and a layer of steel is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com