A kind of preparation method of composite silver tin oxide electrical contact material

An electrical contact material, silver tin oxide technology, used in contacts, circuits, electrical switches, etc., to achieve the effects of easy penetration, reduced oxidation paths, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

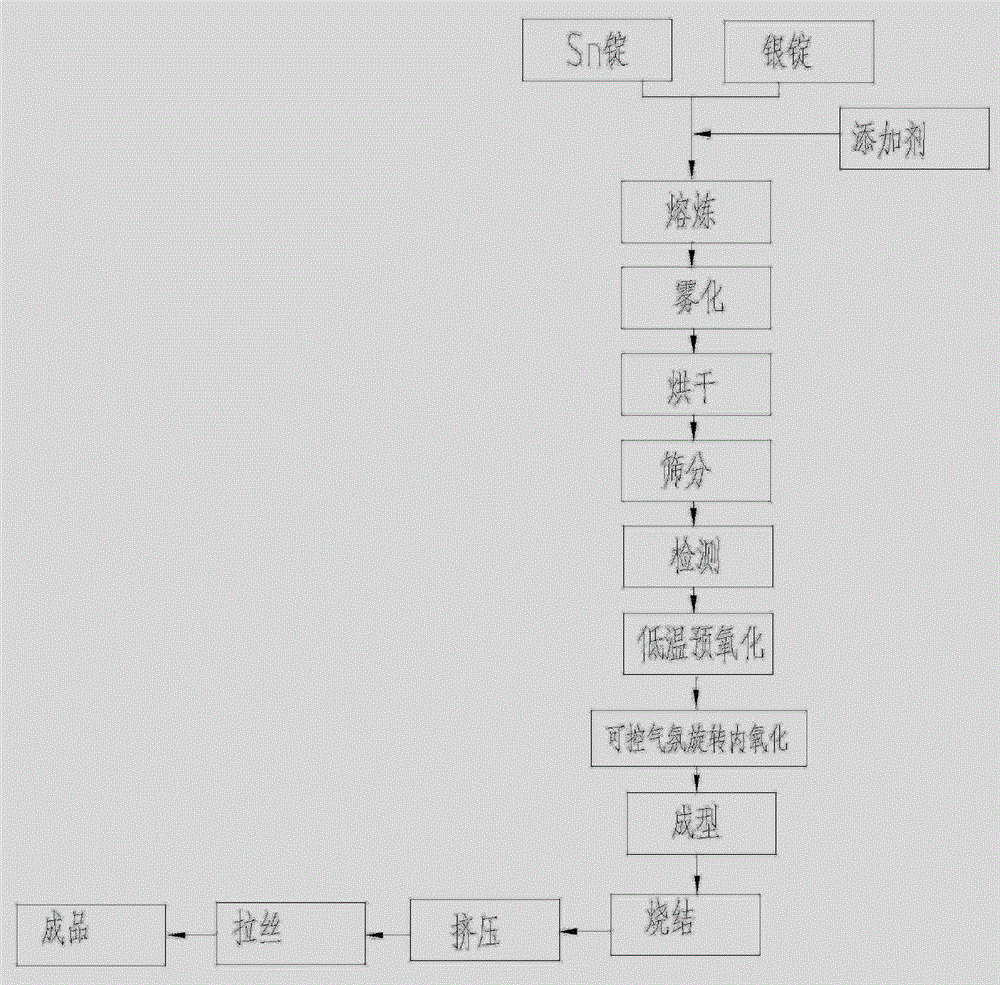

Method used

Image

Examples

Embodiment 1

[0036] Weigh 22.596 kilograms of silver ingots, 1.968 kilograms of Sn ingots, 0.336 kilograms of Bi ingots, and 0.100 kilograms of Cu ingots, a total of 25 kilograms of raw materials are melted and alloyed in an intermediate frequency melting furnace. The water is atomized into alloy powder under the pressure of the nozzle, the powder is dried at 200°C for 24 hours, sieved on a 200-mesh sieve to remove the oversize, and the particle size of the undersize powder is detected by a laser particle size analyzer to ensure that the particle size of the powder is less than 80 microns. The powder extraction rate is 80-90%.

[0037] The -200 mesh alloy powder was pre-oxidized in an oven, and the pre-oxidation was kept at 300°C for 2 hours, at 400°C for 2 hours, and at 500°C for 2 hours.

[0038] Pour the pre-oxidized powder into a controlled atmosphere rotary oxidation furnace for oxidation. The inclination angle of the rotary furnace is 15°, the compressed air flow rate is 5 liters per...

Embodiment 2

[0044] Weigh 22.596 kilograms of silver ingots, 1.968 kilograms of Sn ingots, 0.336 kilograms of Bi ingots, and 0.100 kilograms of Cu ingots, a total of 25 kilograms of raw materials are melted and alloyed in an intermediate frequency melting furnace. The alloy powder is gas-atomized under the pressure of the nozzle, and the powder is dried at 200°C for 24 hours, sieved on a 200-mesh sieve to remove the oversize, and the particle size of the undersize powder is detected by a laser particle size analyzer to ensure that the particle size of the powder is less than 80 microns. The powder extraction rate is 85-95%. Others are with embodiment 1.

[0045] The results of scanning electron microscope analysis of the cross-section of the wire product show that SnO 2 The particle size is between 0.2-0.5 microns, and no SnO2 particles larger than 1.2 microns are seen. The EDX scanning of the components of tin, indium and nickel shows that the added elements are evenly distributed in the...

Embodiment 3

[0049] Pour the pre-oxidized powder into a controlled atmosphere rotary oxidation furnace for oxidation. The inclination angle of the rotary furnace is 0°, the compressed air flow rate is 20 liters per minute, and the rotary furnace rotates in a unidirectional manner with a rotation speed of 60 rpm. / min, keep warm at 620°C for 2 hours, 680°C for 2 hours, and 770°C for 5 hours. Others are the same as embodiment 1.

[0050] The metallographic observation of the wire products was carried out at 100 to 1000 times the cross-section and the longitudinal section respectively. Both the low-magnification and high-magnification observation results showed that SnO 2 The particles are evenly distributed in the silver matrix. Ten different parts of the wire product were sampled for chemical composition analysis, and the average silver content was 87.99%, with a relative standard deviation of 0.50%, indicating that the composition of the product was uniform.

[0051] The results of scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com