Chemical reaction method for reducing free TDI (toluene diisocyanate) in non-toxic polyurethane curing agent

A chemical reaction and polyurethane technology, applied in the field of trimerization catalyst synthesis, can solve the problems of high free diisocyanate TDI content, low free TDI content, complex process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

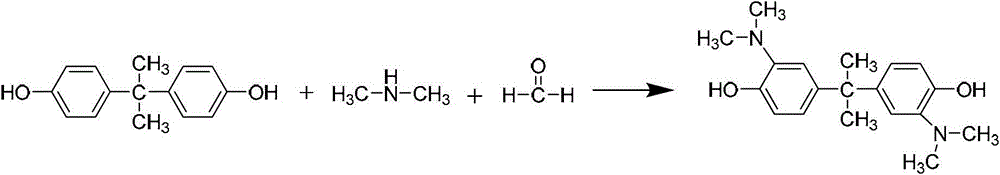

[0027] The preparation of Mannich base: in parts by weight, 188 parts of bisphenol A, 720 parts of 25% dimethylamine solution (the aqueous solution of dimethylamine, mass concentration) and 425 parts of 40% formaldehyde solution (formaldehyde aqueous solution, mass concentration) was heated at 80°C for 2 hours, after cooling, after the organic phase was separated, vacuum distillation was carried out at 90°C / 1.33Kpa to obtain the Mannich base to be prepared, and the reaction equation was as follows:

[0028]

[0029] In a four-neck flask equipped with a thermometer, an electromagnetic stirrer, and a reflux condenser, under the protection of nitrogen, add 153g of TDI-80 and 194.49g of butyl acetate, keep the water bath at 40°C, and stir for 10 minutes to make it evenly mixed. The mass ratio of 2,4-TD to 2,6-TDI in TDI-80 is 8:2. 26.19g of trimethylolpropane (TMP) was dehydrated with benzene, heated and melted, and kept in a liquid state using a heat preservation device. Then...

Embodiment 2

[0031] Preparation of Mannich base: The preparation method is the same as in Example 1, except that the phenol used is tert-butylphenol.

[0032] The NCO / OH molar ratio of toluene diisocyanate (TDI-80) and diethylene glycol is 3:1, and the water content of diethylene glycol is removed with xylene, and TDI-80 is added to the reaction kettle. The alcohol was added dropwise in half an hour, and under the protection of nitrogen, ethyl acetate was added as a solvent, and the reaction was carried out at 55° C. for 2 hours. Add 2,4-TDI whose mass is 10% of the initial isocyanate mass into the polyurethane prepolymer, and dropwise add the Mannich base catalyst prepared from p-tert-butylphenol, the amount of the catalyst is 0.1% of 2,4-TDI , 30 minutes to drop. The temperature was raised to 60° C. to continue the reaction for 4 hours, and phosphoric acid was added to terminate the reaction. Inhibitor phosphoric acid consumption is 1% of raw material gross weight. Cool down, stop and...

Embodiment 3

[0034] Preparation of Mannich base: The preparation method is the same as in Example 1, except that the phenol used is hexafluorobisphenol A.

[0035]The ratio of TDI-80 and glycerol is 4:1 according to the NCO / OH molar ratio, wherein the glycerol is dehydrated with cyclohexanone; add TDI-80 to the reaction kettle, and the glycerol is added dropwise in 40 minutes , under the protection of nitrogen, add toluene and xylene in a mass ratio of 1:1 and mix as a solvent, and react at 50° C. for 3 hours. Add 2,4-TDI whose mass is 20% of the initial isocyanate mass into the polyurethane prepolymer, then dropwise add hexafluorobisphenol A as the catalyst of the raw material, the amount of the catalyst is 0.05% of 2,4-TDI, drip for 40 minutes Finished adding. The temperature was raised to 75°C to continue the reaction for 4 hours, and acetyl chloride was added as a polymerization inhibitor. The amount of polymerization inhibitor acetyl chloride is 1% of the total weight of raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com